B21, China Town Mall, Midrand

Digital Printer for Sublimation Paper Using by Best Model GB1823

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62362896791

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the exact model name and purpose of this printer?

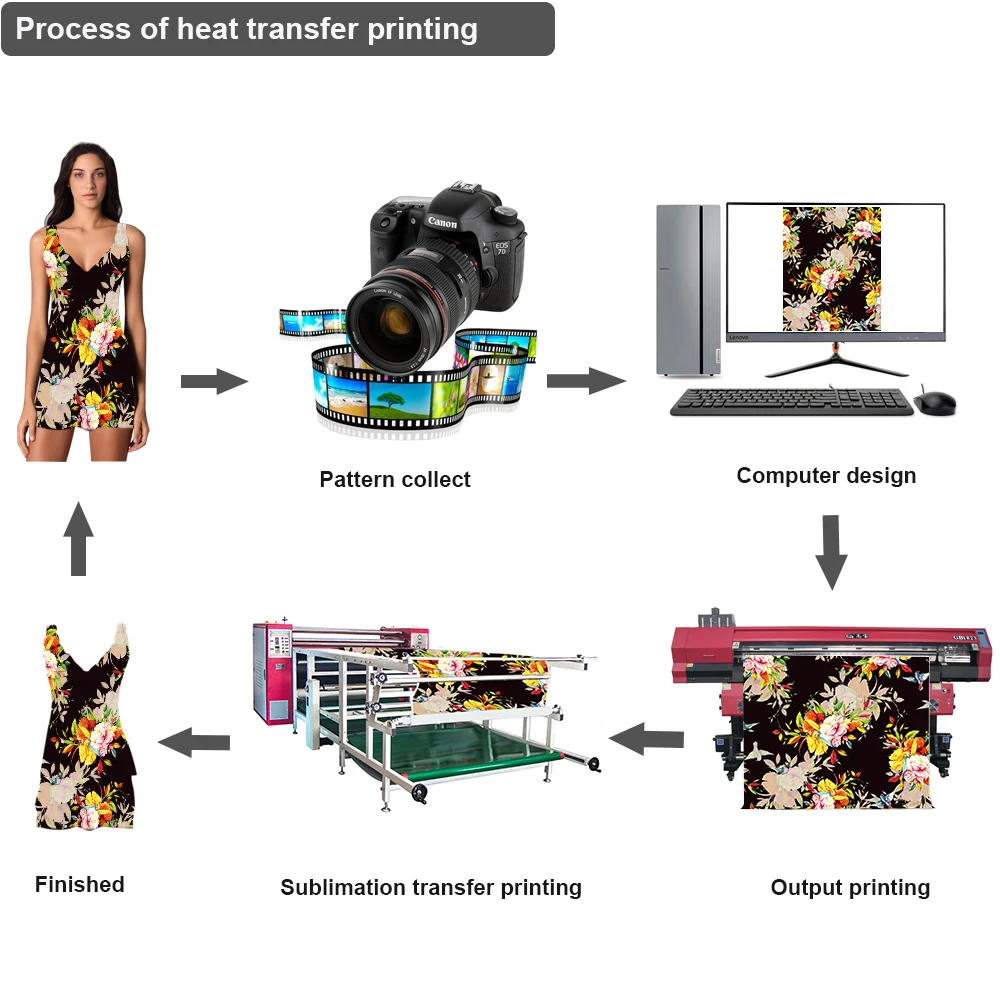

The model is GB1823 — the High Effects Digital Printer for Sublimation Paper Using. It is an automatic flatbed digital printer designed to print high-quality, multicolor images onto sublimation paper for subsequent heat transfer to polyester textiles and coated substrates.

2. What is the maximum printing width/size?

The printer supports a maximum printing width of 1.8 meters, making it suitable for large-format sublimation paper and large production runs.

3. How fast does the printer operate?

Rated printing speed is up to 60 square meters per hour, depending on print mode, resolution, RIP settings and media used.

4. Which print heads does the GB1823 use?

The GB1823 is equipped with double Epson 5113 print heads for consistent multicolor output.

5. What type of ink and media should I use?

This model is designed for sublimation workflows: use heat-transfer (sublimation) inks and compatible sublimation paper. Use inks recommended or certified by the supplier/manufacturer to ensure color stability and avoid damaging the Epson 5113 heads.

6. What are the electrical and power requirements?

Operating voltage is AC 220V, 50–60 Hz. The listed power range is 200–2500 W. Always provide a stable, properly grounded power supply; consider a surge protector or UPS for production environments.

7. What are the machine dimensions, packing size and weight?

Machine dimensions: 3.07 m (L) × 0.75 m (W) × 1.38 m (H). Packing size: 3.25 m × 0.95 m × 0.95 m. Net weight: approximately 300 kg.

8. Which software or RIP does the printer work with?

The GB1823 is compatible with common RIP software and standard printer drivers used for industrial sublimation workflows. For best results, request the specific driver and recommended RIP from the supplier to ensure correct color management and workflow integration.

9. Is installation and training provided?

The printer is automatic and user-friendly, but professional installation and initial training are recommended. Availability of onsite setup and training varies by supplier — confirm with your vendor at the time of purchase.

10. What regular maintenance is required?

Regular maintenance includes print head cleaning (automatic/manual routines), using recommended inks and media, keeping the environment dust-free, checking and replacing maintenance parts (wipers, capping stations) as needed, and periodic inspection of electrical and mechanical components.

11. What are common troubleshooting steps for print quality issues?

For banding, missing nozzles or color shifts: run nozzle checks and head cleaning routines, verify ink supply and flow, check RIP settings and color profiles, ensure stable power, and inspect for clogged or damaged nozzles. Contact technical support for persistent issues.

12. What consumables and spare parts should I budget for?

Typical consumables include sublimation inks, sublimation paper, maintenance fluids, cleaning kits, wipers and caps. Wear parts include print head maintenance components; keep spare inks and basic maintenance parts on hand. For print head replacement (Epson 5113) consult the supplier for availability and cost.

13. Can the GB1823 print directly on fabrics or only on sublimation paper?

The GB1823 prints onto sublimation paper. Final image transfer to fabrics or hard substrates is achieved by heat transfer (sublimation) onto polyester textiles or specially coated items — it does not perform the heat transfer step itself.

14. Is this printer suitable for small workshops or home use?

The printer has a compact industrial footprint for its capacity (3.07 m × 0.75 m) but weighs ~300 kg and requires 220V power and a stable production area. It's suitable for small-to-medium production shops rather than typical home environments.

15. What warranty and technical support are available?

Warranty terms and support packages vary by seller and region. Ask your supplier for warranty period, what is covered (heads, electronic parts, onsite support), and availability of spare parts and service before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading