B21, China Town Mall, Midrand

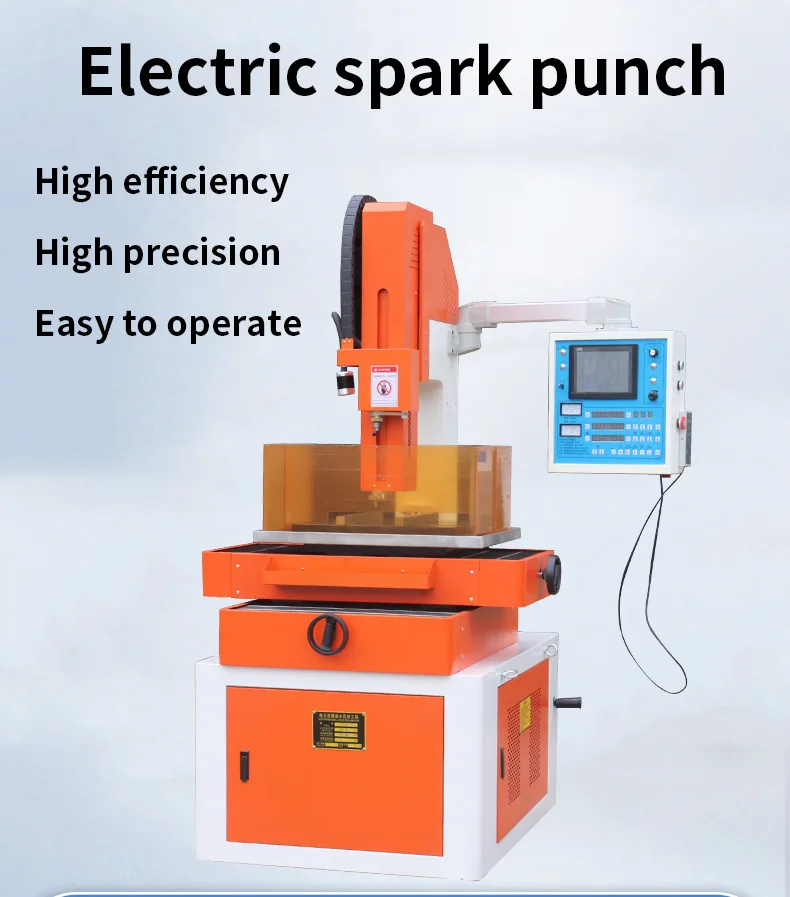

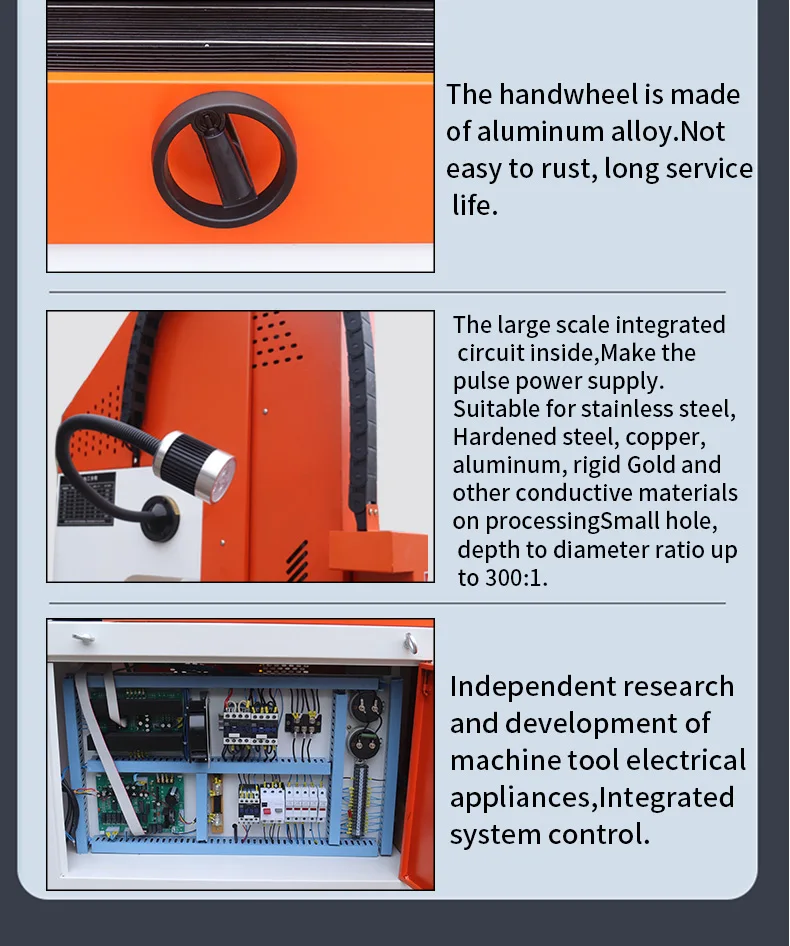

DD703.50 CNC Drilling Machine

- Section : Machinery

- Category : CNC industrial Machinery

- SKU : 1600717616915

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 18 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What are the key specifications of the DD703.50 CNC Drilling Machine?

Key specs: spindle speed range 20–130 r.p.m (see note below), drilling speed 30–60 mm/min, motor power 3 kW, machine weight ~2500 kg, worktable 700 × 1000 mm, X-Y travel 500 × 630 mm, spindle servo stroke 600 mm, electrode clamping diameter 0.3–3.0 mm, maximum distance between head (director) and table 500 mm. Dimensions (DD703.50): 2000 × 1500 × 1900 mm.

2. What is the spindle speed range?

The product description lists a variable spindle speed from 20 to 130 r.p.m. Note: the detailed spec table lists 20–120 r.p.m for both models. Please confirm the exact delivered spindle-speed range with your supplier if precise upper-end RPM is critical for your application.

3. What is the drilling/feed speed?

The drilling speed (feed) range is 30–60 mm/min, suitable for controlled, precision drilling across a variety of materials.

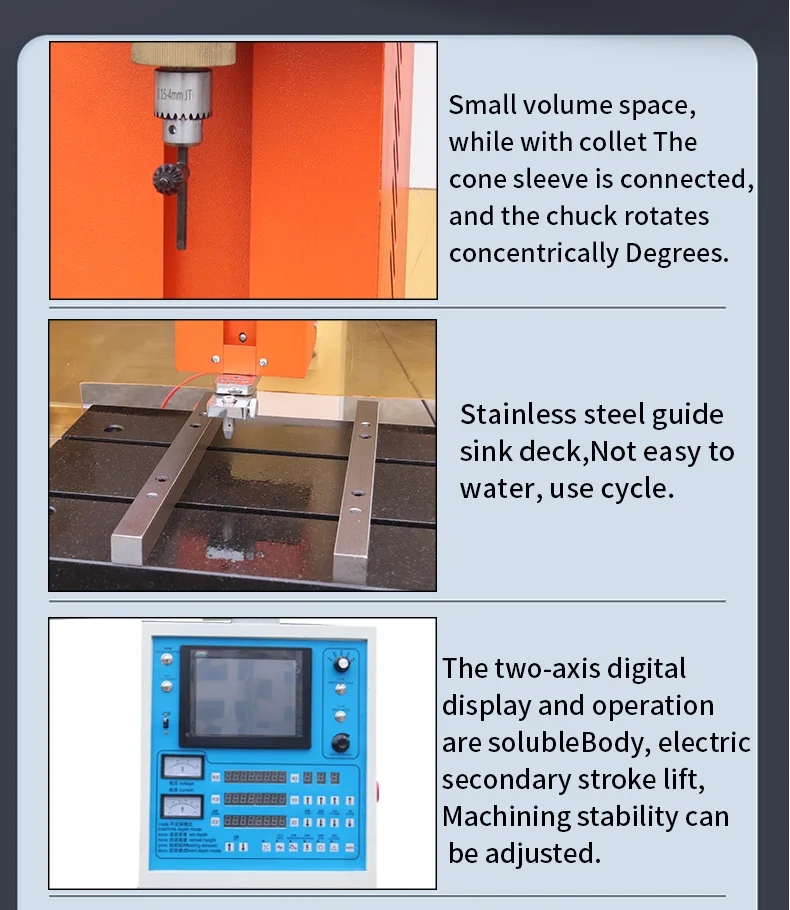

4. What electrode sizes does the DD703.50 accept?

It clamps electrode wires with diameters from 0.3 mm up to 3.0 mm, covering a wide range of small-diameter tooling and electrode applications.

5. What are the differences between model DD703.30 and DD703.50?

Main differences: X-Y travel (DD703.30: 300 × 400 mm; DD703.50: 500 × 630 mm), workbench size (DD703.30: 260 × 380 mm; DD703.50: 700 × 1000 mm), spindle servo travel (DD703.30: 300 mm; DD703.50: 600 mm), spindle head travel (DD703.30: 200 mm; DD703.50: 500 mm), and overall dimensions (DD703.30: 1260 × 1160 × 1900 mm; DD703.50: 2000 × 1500 × 1900 mm). Choose DD703.50 for larger workpieces and greater travel.

6. What materials can the DD703.50 drill?

The DD703.50 is designed for a wide range of materials including common metals, plastics and composite materials used in precision drilling. Material-specific performance depends on tooling, electrode type, feed/speed settings and coolant; consult the vendor for recommendations for very hard or exotic materials.

7. What power and electrical requirements does the machine have?

The machine’s input power is 3 kW. Exact electrical requirements (voltage, phase, breaker size) depend on the configuration and your region—confirm with the supplier or your electrician for proper supply and circuit protection.

8. What are the machine weight and footprint?

The DD703.50 weighs approximately 2500 kg. Its nominal dimensions are 2000 × 1500 × 1900 mm. Ensure your floor/load-bearing structure can support this weight and that you have sufficient space for access and maintenance.

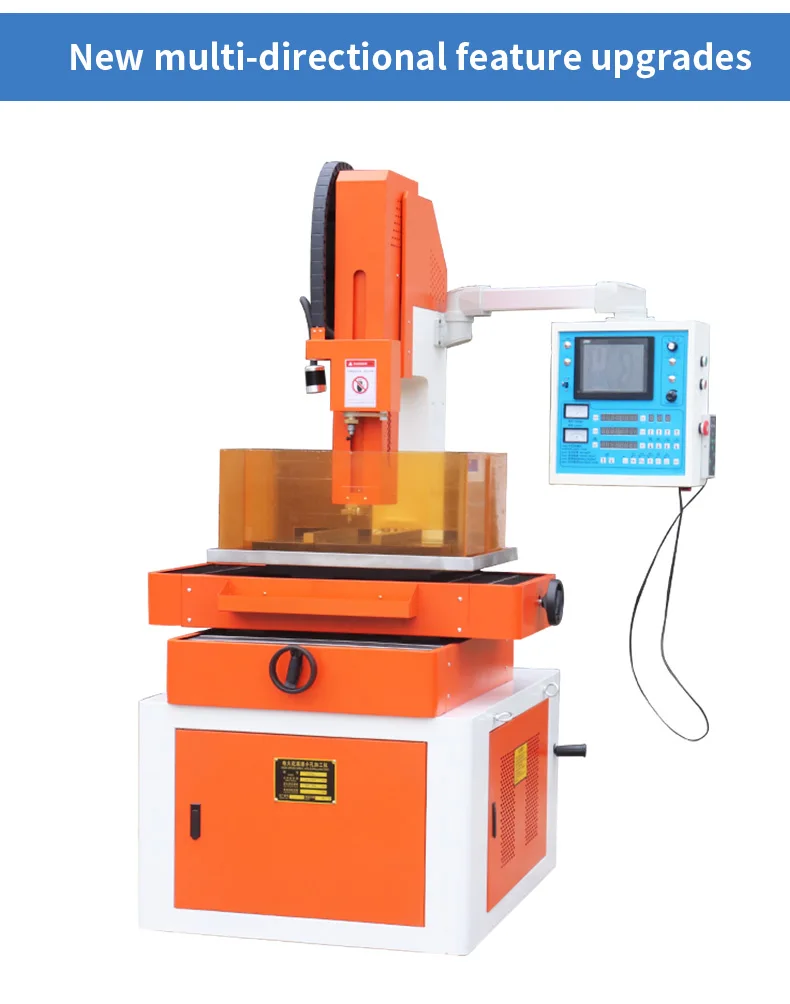

9. What CNC control and software does the machine use? Is it compatible with standard G-code?

The DD703.50 is equipped with CNC control for precise drilling. Controller type and software compatibility can vary by configuration—many units support standard G-code or vendor-specific control software. Confirm the exact controller model and file/communication formats with the supplier if you require specific CAM/CNC integration.

10. What installation and foundation requirements are there?

The machine should be placed on a level, stable floor capable of supporting its weight. Some installations may require anchoring or a reinforced foundation to minimize vibration. Professional installation and alignment by authorized technicians is recommended.

11. What routine maintenance does the DD703.50 require?

Routine maintenance typically includes regular cleaning of chips/contaminants, lubrication of guides and moving parts, inspection and tightening of fixtures, periodic spindle checks and calibration, and replacement of worn consumables (electrodes, clamps, seals). Follow the vendor’s maintenance schedule for intervals and procedures.

12. Are spare parts and after-sales service available?

Spare parts and after-sales service availability depend on your supplier and region. Ask your vendor about local stocking of critical spares, recommended spare parts list, service contracts and authorized service providers before purchase.

13. What safety features should I expect, and is operator training provided?

Typical safety features include emergency stop, guarded moving parts, electrical protection and interlocks. Operators should receive training on safe operation, PPE use, machine controls and emergency procedures. Confirm with the supplier what safety equipment and training are included or available as add-ons.

14. Can the DD703.50 handle large workpieces and how is workpiece fixturing handled?

The 700 × 1000 mm worktable and 500 × 630 mm X-Y travel allow handling of relatively large workpieces within those travel limits. Workpiece fixturing is application-dependent—use appropriate clamps, fixtures or vacuum tooling rated for precision drilling; consult the supplier for recommended fixturing solutions for your parts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading