B21, China Town Mall, Midrand

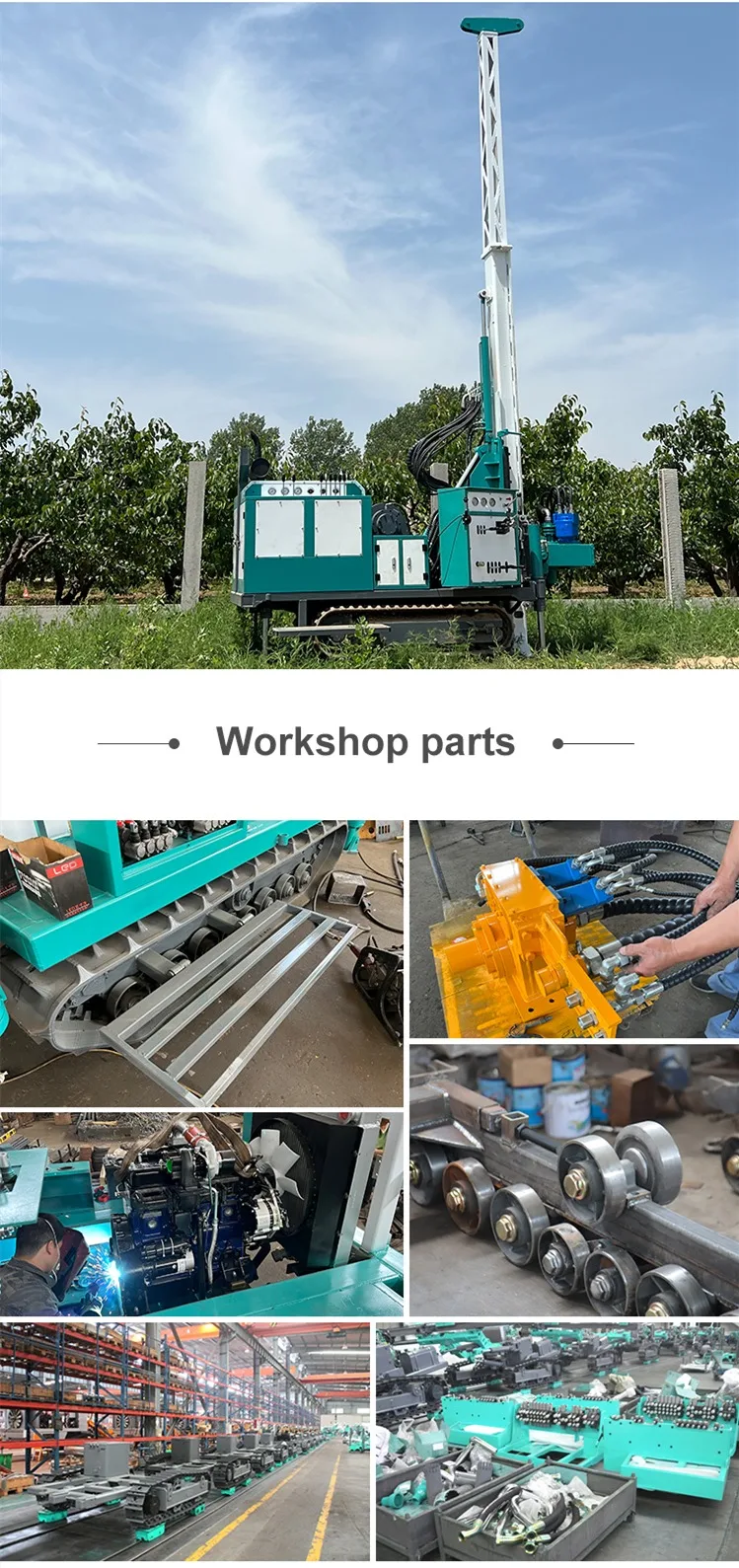

Crawler Mounted Water Well Bore Hole Diesel power Drilling Rig Mining Machinery

- Section : Electrical & Tools

- Category : Power Drills

- SKU : 1600541513006

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 13 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the HANFA Core Water Well Drilling Rig?

The HANFA Core Water Well Drilling Rig is a crawler-mounted, diesel-powered drilling machine engineered for water well and rock/core drilling up to 300 meters. It is compact, moveable, and built with motors, pumps and bearings for reliable field performance.

2. What are the main specifications of the rig?

Key specs: maximum drilling depth 300 meters; dimensions 3200mm (L) x 1400mm (W) x 1500mm (H); weight 430 kg; diesel-powered; core components include motors, pumps and bearings; 1-year warranty.

3. What applications is this drilling rig suitable for?

It is suitable for potable water well drilling, deep water wells, core sampling in rock/soil, construction and mining boreholes, and geotechnical or environmental drilling projects.

4. Is the rig truly mobile and easy to transport between sites?

Yes—at 430 kg and compact dimensions the rig is designed to be moveable. It can be relocated on site and transported on a small trailer or truck bed; specific transport requirements depend on local regulations and the vehicle used.

5. What does the 1-year warranty cover?

The 1-year warranty covers defects in materials and workmanship under normal use. Consumables, wear parts, damage from misuse, and routine maintenance are typically excluded. For full terms and claim procedures, consult HANFA's warranty documentation.

6. Are mechanical test reports and factory inspection videos available?

Yes. HANFA provides a mechanical test report and offers a video factory inspection upon request to demonstrate build quality and operation before shipment.

7. What safety equipment and protections are recommended when operating the rig?

Operators should use PPE including hard hats, safety glasses, hearing protection, gloves and steel-toe boots. Follow lockout/tagout procedures for maintenance, maintain clear exclusion zones around the rig, and adhere to local safety standards and operator training requirements.

8. What kind of drill bits and consumables are compatible?

The rig supports standard core and water-well drilling tooling appropriate for the bore size and formation (e.g., diamond core bits, tricone bits, augers, casing). Specific bit selection depends on geology; consult HANFA or your tooling supplier for recommendations.

9. How often does the rig require maintenance and what routine checks are recommended?

Routine maintenance includes daily visual checks, fluid levels and fuel, weekly lubrication of moving parts, regular inspection of pumps, hoses and electrical connections, and periodic replacement of filters and wear parts per the operator manual. A scheduled service every few hundred operating hours is recommended.

10. What are the site requirements and ground conditions for operation?

A relatively level staging area large enough for the rig and support equipment is required. The rig handles a variety of ground conditions, but very soft or unstable ground may require mats or temporary work platforms. For hard rock drilling, suitable drilling tools and procedures must be used.

11. What is the fuel consumption and running time on a full tank?

Fuel consumption depends on drilling depth, load, and duty cycle. Exact fuel use and tank capacity vary by engine configuration; please contact HANFA with your expected drilling profile to receive an estimated consumption and runtime.

12. Are spare parts and after-sales support available?

Yes. HANFA supplies spare parts and provides after-sales support. Common wear parts such as seals, bearings, filters and pump components are available; contact HANFA or an authorized dealer for parts lists and lead times.

13. Is operator training provided or required?

HANFA recommends trained operators. Training can be provided by HANFA or authorized partners and typically covers safe operation, routine maintenance, troubleshooting and transport/set-up procedures.

14. Can the rig be customized or adapted for specific projects?

HANFA can often provide customization options—such as different mast lengths, auxiliary pumps, or tooling interfaces—depending on project requirements. Contact HANFA with your specifications to discuss options and pricing.

15. How do I purchase the rig and what are typical lead times?

To purchase, contact HANFA or an authorized dealer for a quote, including shipping, customs and optional accessories. Lead times depend on stock and custom options; HANFA can provide estimated delivery times once order details are finalized.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading