B21, China Town Mall, Midrand

Construction Equipment Automatic PLC Mortar Cement Mixer Intelligent Grouting Trolley

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600254299704

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 25 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

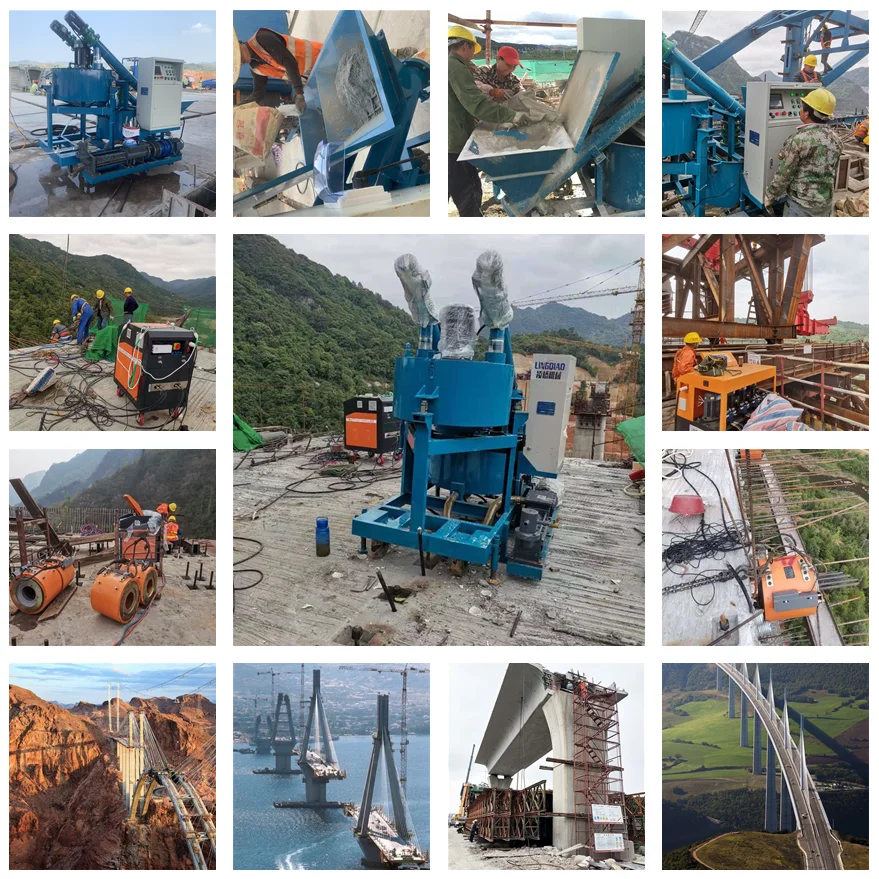

1. What is the Construction Equipment Automatic PLC Mortar Cement Mixer Intelligent Grouting Trolley?

A mobile grouting trolley that automatically mixes, measures and delivers mortar/cement slurry. It combines an automatic feeding system, precision weighing, PLC-based microcomputer control, high- and low-speed mixing, water supply and a walking system for continuous grouting on construction sites.

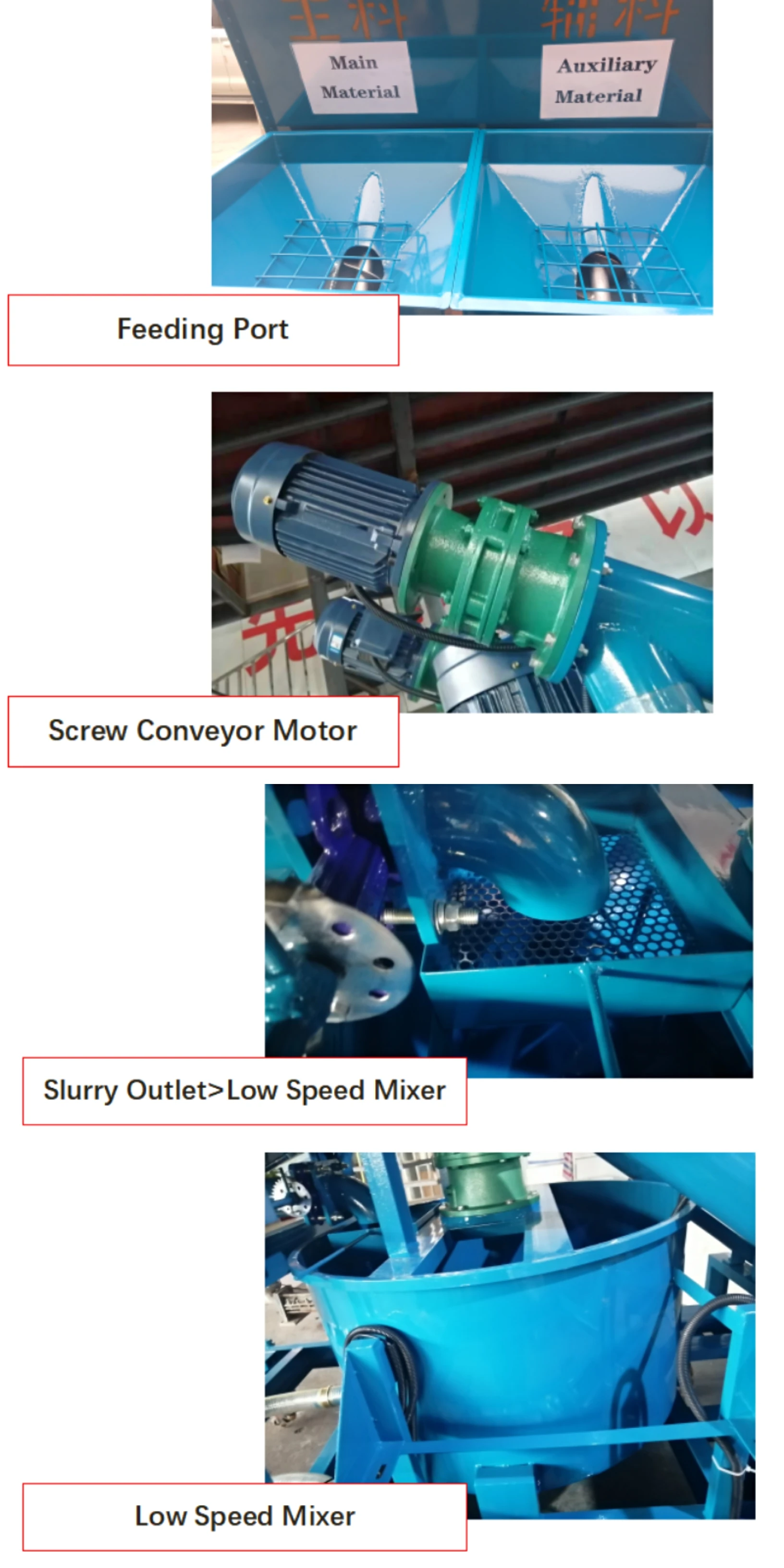

2. What are the main components of the machine?

Automatic screw feeding system, automatic weighing system, microcomputer/PLC control system (with memory), high-speed mixing drum, low-speed storage drum, water supply system and a walking/dragging frame.

3. What is the mixing capacity and hourly output?

High-speed mixing batch capacity is 350 kg. When manually controlled, the machine can produce approximately 4,000–7,000 kg of slurry per hour. The low-speed storage barrel holds 400 kg to enable continuous feeding.

4. What are the mixing speeds and motor powers?

High-speed agitator: 1430 r/min with a 7.5 kW motor. Low-speed (storage) agitator: 45 r/min with a 2.2 kW motor. Automatic charging uses two screw conveyors, each powered by a 1.5 kW motor.

5. How accurate is the weighing and control system?

The microcomputer automatic control system offers accurate measurement to two decimal places with measuring accuracy better than ±1% of the rated mixing volume. The system includes memory functions for repeatable mixes.

6. What type of feeding/charging system does it use?

The machine uses a screw conveying automatic charging system (two 1.5 kW screw conveyors) to feed raw material into the mixer reliably and consistently.

7. What are the machine dimensions, weight and mobility specs?

Overall dimensions: 2800 × 1450 × 2200 mm (L × W × H). Total weight: 887 kg. Dragging (travel) speed is less than 20 km/h, making it suitable for site mobility. For transport on public roads, follow local regulations.

8. What is the control system used?

The machine uses the Liuzhou automatic grouting control system — a PLC/microcomputer-based controller providing automatic and manual operation modes, memory of mix recipes and precision weighing control.

9. Where is this trolley typically used?

Used in building construction, bridge construction and other civil engineering projects requiring grout, mortar or cement slurry application and continuous grouting operations.

10. What power supply is required?

The specification lists individual motor powers (high-speed 7.5 kW, low-speed 2.2 kW, charging 2 × 1.5 kW). Exact site power voltage, phase and total supply configuration should be confirmed with the supplier or in the machine's technical manual.

11. How is the machine installed and commissioned on site?

Place the trolley on a stable, level surface; secure power and water connections; check and connect the screw conveyors and motors; calibrate the weighing system per the manual; run initial no-load and trial mixes to verify settings. Installation and commissioning should be done by trained personnel or authorized technicians.

12. What routine maintenance is required?

Daily cleaning of mixing drums and conveyors after use, inspect and tighten fasteners, lubricate bearings and moving parts as recommended, check seals and wear parts (agitator blades, screws), verify sensor and weighing accuracy periodically, and schedule motor/electrical inspections per the manual.

13. What safety features and operator protections are provided?

The machine is controlled by a PLC with automatic control functions. Operators should follow the supplier's safety manual, use required PPE, and rely on built-in safety interlocks/emergency stop functions if provided. Confirm specific safety devices and certifications with the manufacturer.

14. What spare parts are commonly needed and how to obtain them?

Common spares include agitator blades, screw conveyor augers, seals, wear liners, sensors and electrical/PLC components. Obtain genuine parts and service from the manufacturer or authorized dealers to ensure fit and performance.

15. Is training or warranty provided?

Training, warranty terms and after-sales service vary by supplier. Contact the manufacturer or your equipment provider for details on operator training, commissioning support and warranty coverage.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading