B21, China Town Mall, Midrand

CNC lathe intelligent manufacturing

- Section : Machinery

- Category : CNC industrial Machinery

- SKU : 1600998348356

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a CNC lathe and how does it work?

A CNC lathe is a computer-controlled machine tool that uses rotating workpieces to perform various machining operations such as turning, drilling, and milling. It operates by following programmed instructions to achieve precise shapes and dimensions.

2. What industries can benefit from using a CNC lathe?

CNC lathes are versatile machines used in various industries including aerospace, medical, automotive, electrical, and hydraulic sectors for manufacturing high-precision components.

3. What are the key specifications of the FCL-280 CNC lathe?

The FCL-280 CNC lathe features a spindle speed of 4,000 rpm, a maximum cutting diameter of Ф300 mm, and a maximum workpiece length of 460 mm. It is powered by a 7.5/11 kW spindle motor and has a positioning accuracy of ±0.005 mm.

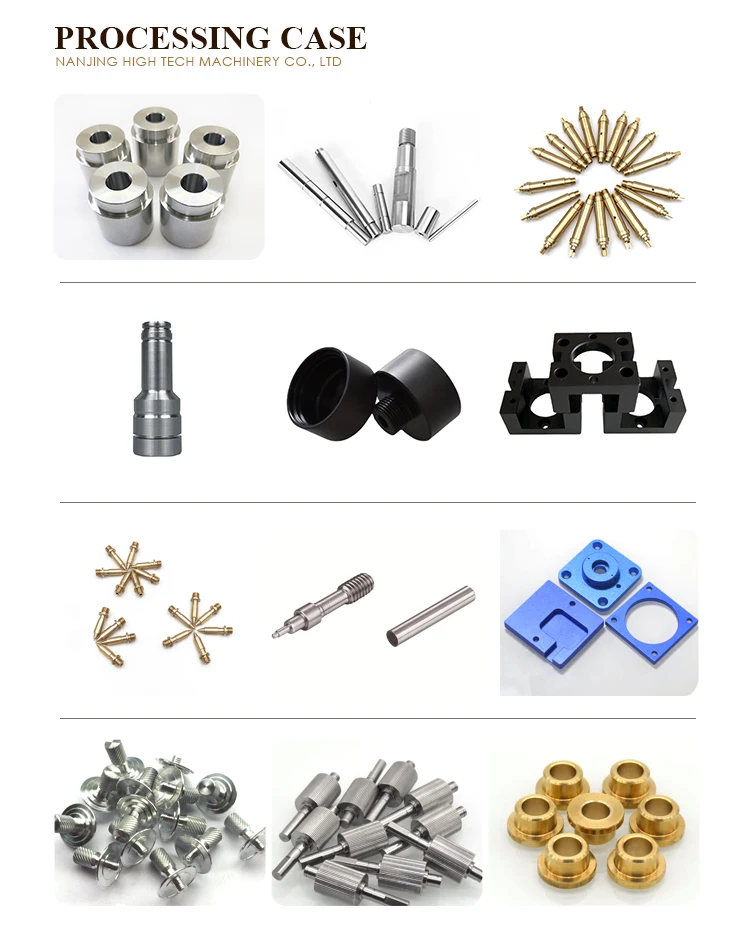

4. What types of components can be machined with this CNC lathe?

This CNC lathe can machine a wide variety of components, including shaft components, valve components, aerospace components, electrical components, medical components, automotive components, hydraulic components, mold components, precision gears, and sports equipment components.

5. What is the maximum weight and dimensions of the FCL-280 CNC lathe?

The FCL-280 CNC lathe weighs 3100 kg and has dimensions of 2000 mm in length, 1650 mm in width, and 1780 mm in height.

6. What is the importance of positioning accuracy in CNC lathes?

Positioning accuracy is crucial in CNC lathes as it ensures that the machined components meet tight tolerances and specifications, leading to better quality and reliability in the final products.

7. Can the FCL-280 CNC lathe be used for complex designs?

Yes, the FCL-280 CNC lathe is equipped with advanced technology and sophisticated programming capabilities, allowing it to easily handle complex designs and achieve tight tolerances.

8. What type of chuck does the FCL-280 CNC lathe use?

The FCL-280 CNC lathe uses a Taiwan hydraulic chuck, which provides strong clamping force and precision for securing workpieces during machining.

9. What is the spindle bore size of the FCL-280 CNC lathe?

The spindle bore size of the FCL-280 CNC lathe is Ф62 mm, which allows for the machining of larger workpieces.

10. Is training available for operating the CNC lathe?

Yes, training is typically available for operators to learn how to effectively use and maintain the CNC lathe, ensuring safe and efficient operation.

11. What is the role of the hydraulic tailstock in the CNC lathe?

The hydraulic tailstock provides support for longer workpieces during machining, improving stability and accuracy while reducing vibrations.

12. What power supply is required for the FCL-280 CNC lathe?

The FCL-280 CNC lathe requires a power supply of 220 V/380 V, accommodating different electrical systems.

13. How does the CNC lathe ensure repeatability in machining?

The CNC lathe achieves repeatability through precise programming and mechanical design, allowing it to consistently produce identical parts with a repeatability of ±0.004 mm.

14. What are the benefits of using a CNC lathe for medical components?

CNC lathes offer high precision and reliability, which are critical for manufacturing medical components like surgical instruments and implants, ensuring safety and functionality.

15. Can the CNC lathe handle materials of varying hardness?

Yes, CNC lathes can be equipped with different tooling and settings to machine materials with varying hardness, making them suitable for diverse applications.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading