B21, China Town Mall, Midrand

CHUNKE Sea Water Desalination Plant – 20,000L/Hour

- Section : Machinery

- Category : Filtration Equipment

- SKU : 1600496879568

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

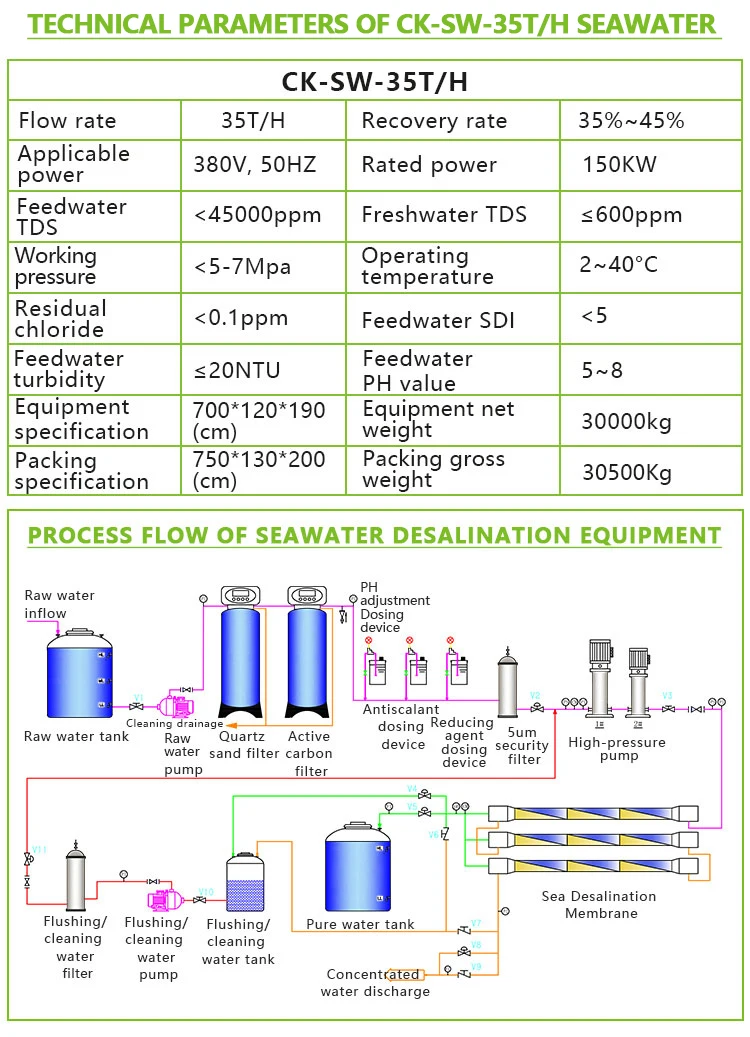

1. What is the production capacity of the CHUNKE Sea Water Desalination Plant – 20,000L/Hour?

The system is rated to process up to 20,000 liters of seawater per hour under standard operating conditions.

2. What level of desalination performance can I expect?

The plant achieves a desalinization efficiency of ≥97% (salt rejection). Actual treated water quality will depend on feedwater characteristics and system configuration.

3. Which reverse osmosis membranes are used and are they replaceable?

High-performance membranes are optional; commonly offered brands include DOW, Toray, and Vontron. Membranes are replaceable and configurable to match site requirements.

4. What materials are available for the system tanks?

Tank material options include durable carbon steel or FRP (fiberglass-reinforced plastic) so you can choose based on environmental conditions and corrosion considerations.

5. How is the system operated and controlled?

The plant includes a PLC control system with both automatic and manual operation modes, enabling customizable control, alarms, and integration with site-level automation.

6. What core components are included with the plant?

Core components include pressure vessels, high-pressure pumps (options from Danfoss or Chinese manufacturers), motors, PLC, pre-treatment filters, and optional CIP and energy recovery devices.

7. Does the system have cleaning and maintenance features?

Yes — the system supports self-cleaning functionality with automatic or manual cleaning options. A CIP (clean-in-place) system is also available as an option for scheduled membrane cleaning.

8. What pre-treatment equipment is supplied?

Standard pre-treatment equipment options include sand filters (e.g., 1800×2400 units in sets), cartridge filters (40" × 50 μm PP), and dosing systems for flocculant, fungicide, reductant and inhibitor as required by feedwater quality.

9. What are the typical applications for this desalination plant?

The system is designed for seawater conversion to drinking water, agricultural irrigation, and various industrial water supply needs.

10. How is brine (concentrate) handled and what is the recovery rate?

Brine disposal must comply with local regulations and is typically handled via discharge, evaporation ponds, or further treatment. Recovery rate depends on feed salinity and system configuration; please consult CHUNKE for an expected recovery percentage for your site.

11. What are the power and utility requirements?

Power and utility consumption vary with pump selection, energy recovery device presence, and local conditions. Please provide site voltage, desired configuration, and feedwater data so CHUNKE can supply detailed power and utilities specifications.

12. What quality assurance and test documentation is provided?

The product is supplied with video outgoing inspection and comprehensive machinery test reports. Additional certificates or factory acceptance test (FAT) documentation can be requested prior to shipment.

13. How often do membranes and consumables need replacement?

Membrane life depends on feedwater quality and maintenance practices; typical lifetimes range from 3–7 years. Pre-filters and cartridge filters require more frequent replacement (weeks to months) depending on turbidity and loading.

14. Can the plant be customized for my project?

Yes — CHUNKE offers configurable options including membrane brand/type, pump selection, tank material, dosing packages, CIP and energy recovery devices to match specific project requirements.

15. What is the typical delivery lead time and after-sales support/warranty?

Lead time and warranty terms vary by configuration and order size. CHUNKE provides after-sales support, commissioning assistance, and spare parts; contact the sales team with your configuration for exact lead times and warranty details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading