B21, China Town Mall, Midrand

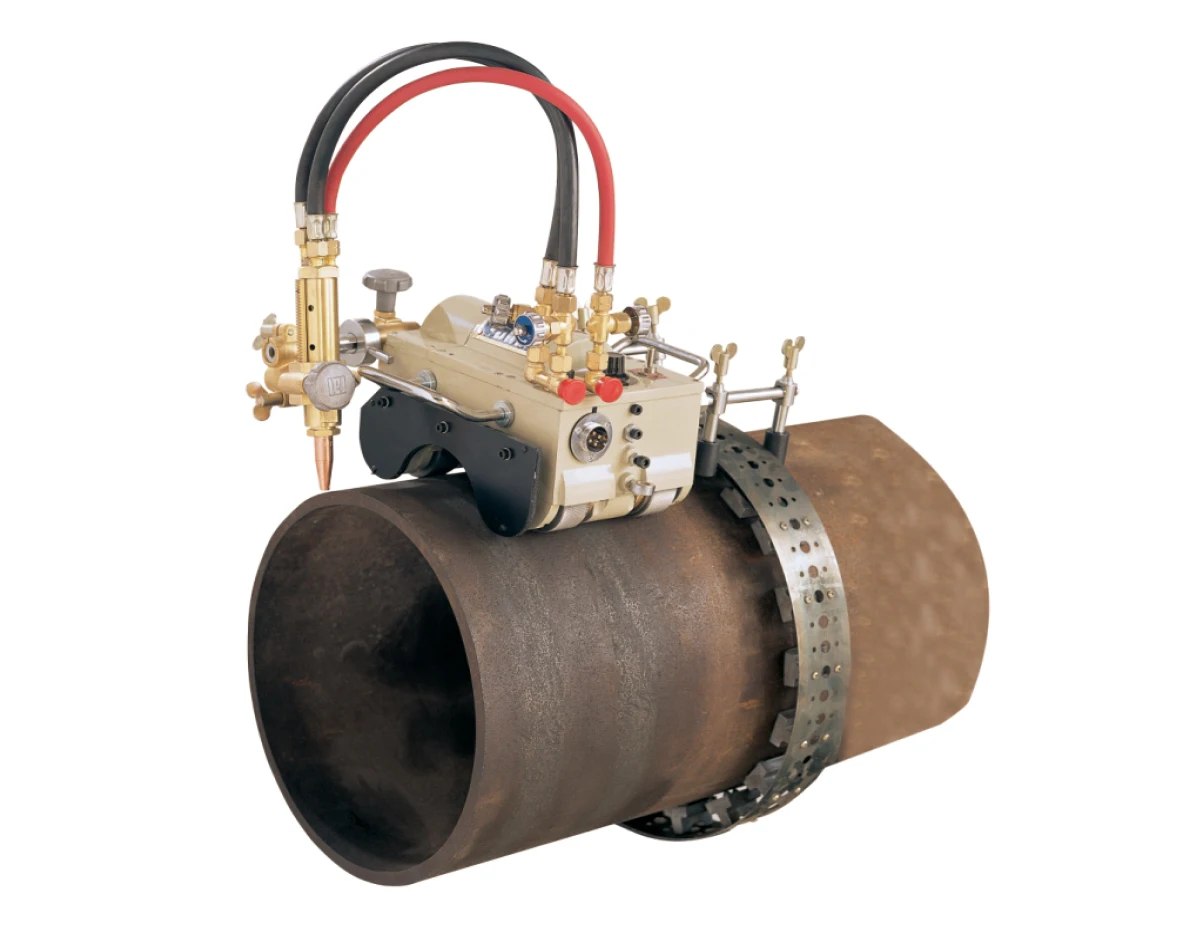

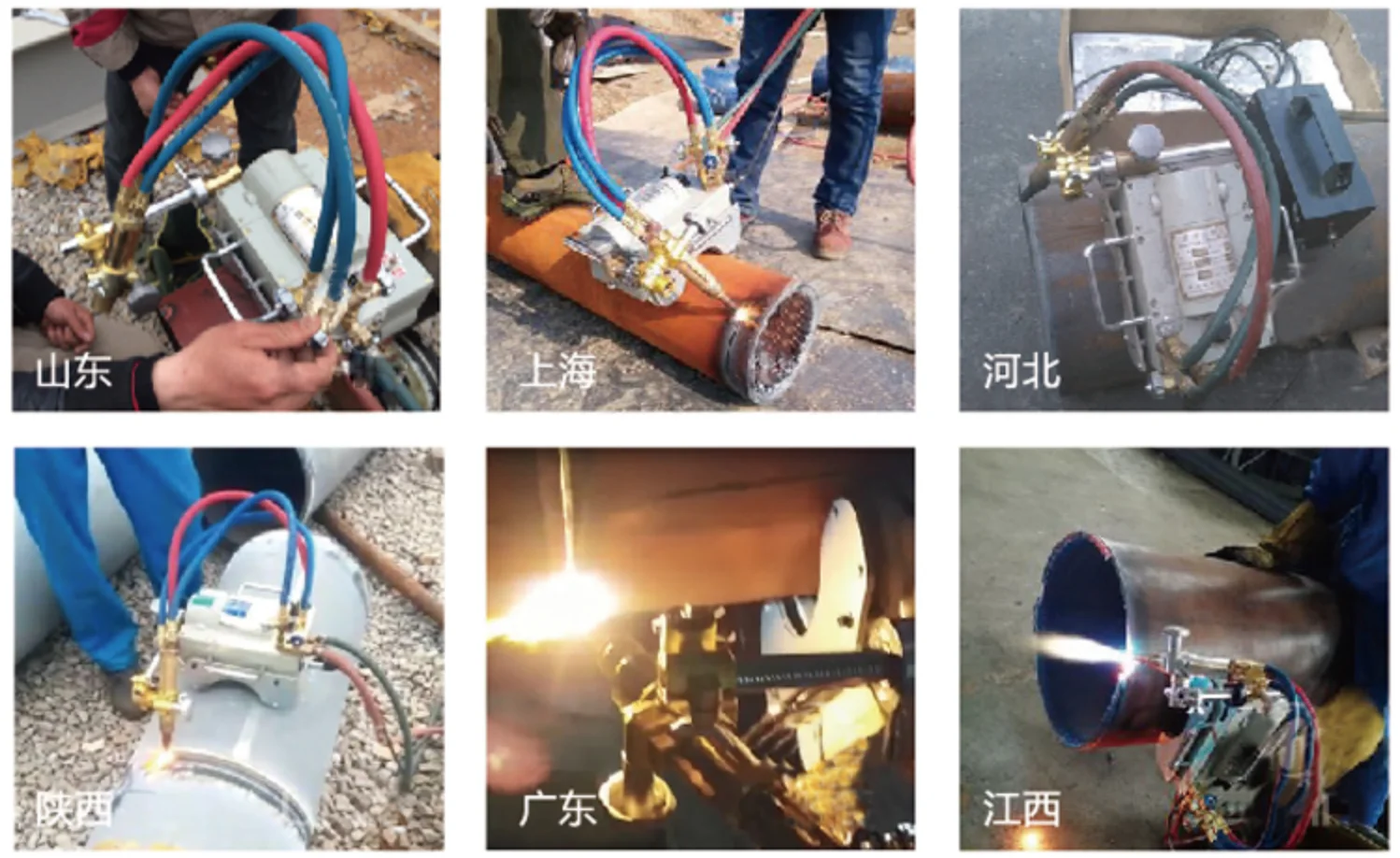

CG2-11 Magnetic Automatic Pipe Gas Cutting Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62016494537

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries is the CG2-11 Magnetic Automatic Pipe Gas Cutting Machine suitable for?

The CG2-11 is widely used in industries such as oil production and chemical piping, making it a versatile tool for various industrial pipe cutting applications.

2. What are the key features of the CG2-11 cutting machine?

Key features include a lightweight aluminum alloy body, magnetic wheel movement, versatile cutting orientations (parallel, upright, face-up), beveling capability up to 45°, and specialized design for pipe cutting.

3. What is the minimum diameter pipe that the CG2-11 can cut?

The CG2-11 can cut pipes with a minimum diameter of 108 mm.

4. How does the magnetic wheel system work?

The magnetic wheel system allows the machine to crawl smoothly along the pipe surface, ensuring stable movement during the cutting process.

5. What materials can the CG2-11 cut?

The CG2-11 can effectively cut through various materials, primarily designed for pipes used in oil and chemical industries.

6. Is the CG2-11 portable?

Yes, the CG2-11 is designed to be lightweight and portable, making it easy to handle during operations.

7. What is the cutting speed of the CG2-11?

The cutting speed of the CG2-11 ranges from 5 to 750 mm/min, allowing for flexibility based on the material and cutting requirements.

8. What safety features does the CG2-11 have?

The CG2-11 includes a thermal baffle to prevent overheating, a reversing switch for direction control, and a speed regulating knob for safe operation.

9. Can the CG2-11 perform bevel cuts?

Yes, the CG2-11 supports beveling at angles of up to 45°, enabling a variety of cutting profiles.

10. What type of gas hoses are included with the CG2-11?

The CG2-11 comes with three hoses for gas distribution: preheating oxygen, fuel gas, and cutting oxygen hoses.

11. Is training required to operate the CG2-11?

While the CG2-11 is designed for ease of operation, users are recommended to undergo proper training to ensure safe and effective use.

12. What is the weight of the CG2-11?

The CG2-11 weighs approximately 20 kg, making it manageable for on-site operations.

13. Does the CG2-11 have a warranty?

Warranty details may vary by supplier, so it's best to check with the retailer for specific warranty information.

14. How is the CG2-11 powered?

The CG2-11 operates on AC220/50 power supply.

15. How do I maintain the CG2-11 cutting machine?

Regular maintenance includes checking the hoses for leaks, cleaning the cutting area, and ensuring the magnetic wheels are functioning properly.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading