B21, China Town Mall, Midrand

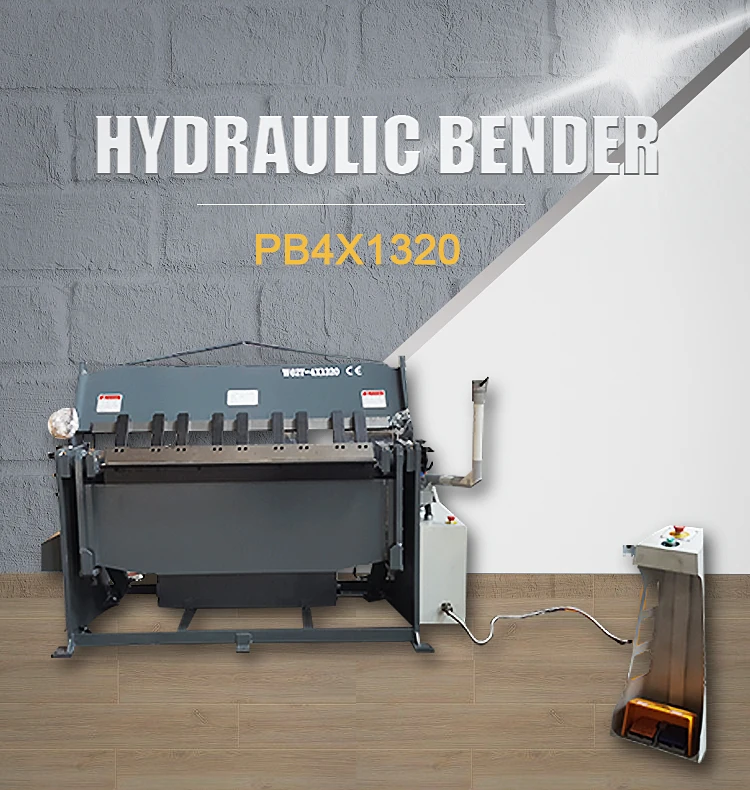

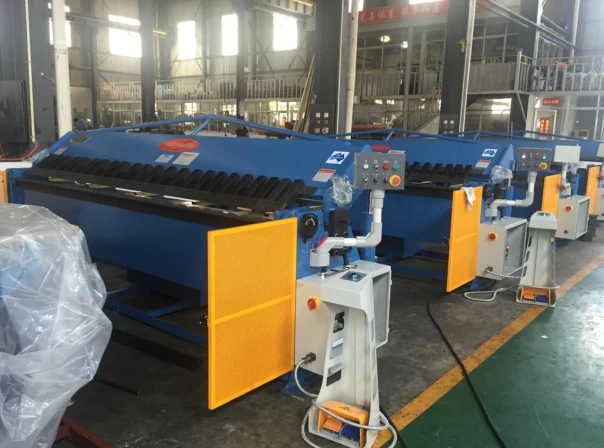

Bending Machines Hydraulic Sheet Metal Folder

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 1600142417442

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum thickness of sheet metal that the hydraulic folding machine can handle?

The hydraulic folding machine can bend sheet metal up to a maximum thickness of 2.5 mm TDF sheet plate.

2. How does the hydraulic folding machine compare to pneumatic folding machines?

The hydraulic folding machine has a higher working speed than pneumatic folding machines and is easier to operate.

3. What is the maximum bending angle of the machine?

The machine allows for a bending angle of up to 130 degrees, making it suitable for flattening light materials.

4. Can the hydraulic folding machine be used with other duct forming machines?

Yes, it can be used in conjunction with other rectangular air duct forming machines to complete a whole duct processing system.

5. What is the function of the foot switch on the machine?

The foot switch is used to control the clamp and unclamp operations, allowing for hands-free operation.

6. What kind of angle control options are available?

The machine features a 10-station NC angle control with 99-job storage for enhanced flexibility and efficiency.

7. What is the significance of the Epic electronic 3 station angle control?

The Epic electronic 3 station angle control allows operators to store three programs, each consisting of the desired bend angle and the open height of the clamp.

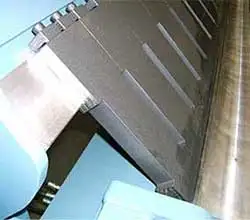

8. What are the dimensions of the fingers used in the machine?

Fingers sizes range from 75 mm to 210 mm, with a thickness capability of 50 mm on the 6.5 mm capacity pan brakes.

9. How is the depth of the pan measured?

The depth of the pan is measured at 150 mm, providing adequate space for various bending operations.

10. Is the hydraulic folding machine suitable for beginners?

Yes, the machine is designed for easy operation, making it suitable for both beginners and experienced operators.

11. What materials can be processed with this machine?

The machine is primarily designed to process TDF sheet plates, but it can also handle light materials effectively.

12. How is the bending angle displayed during operation?

The angle of the apron is continuously displayed on the machine, allowing for precise angle adjustments during the bending process.

13. Can I adjust the head of the machine for different material thicknesses?

Yes, the machine features rapid head adjustments marked from 0.5 mm up to 6.5 mm steel, accommodating various material thicknesses.

14. What is the advantage of having a ball screw back gauge?

The ball screw back gauge works in conjunction with the 10-station controller, providing a 2-axis pan brake for improved accuracy and efficiency.

15. What kind of maintenance does the hydraulic folding machine require?

Regular maintenance includes checking hydraulic fluid levels, ensuring electrical components are functioning properly, and keeping the machine clean to ensure longevity and performance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading