B21, China Town Mall, Midrand

Automation Robots Suction Smt Production Assembled Line Smt Machine Turnkey Solar Panel Production Line For Pcb

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600898586698

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the purpose of the Automation Robots Suction SMT Production Line?

The Automation Robots Suction SMT Production Line is designed to automate the assembly and production of solar panels and printed circuit boards (PCBs), increasing efficiency and precision in manufacturing.

2. What types of products can be produced using this SMT machine?

This SMT machine is capable of producing solar panels and various types of PCBs, making it ideal for industries focused on renewable energy and electronic manufacturing.

3. Is the production line suitable for small-scale operations?

Yes, the production line can be configured for both small-scale and large-scale operations, allowing flexibility in production volume.

4. How does the automation feature improve the production process?

The automation feature reduces human error, increases speed, and ensures consistent quality in the production process, leading to higher output and efficiency.

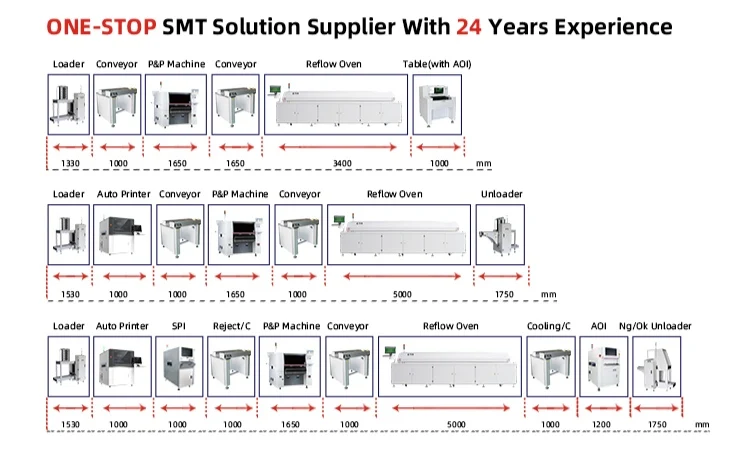

5. What are the key components of the SMT production line?

Key components include automated suction robots, solder paste printers, pick-and-place machines, and reflow ovens, all integrated to streamline the production workflow.

6. Can this production line be customized for specific production needs?

Yes, the production line can be customized with various configurations and components to meet specific production requirements and product types.

7. What is the average setup time for this production line?

Setup time can vary based on the configuration, but typically it ranges from a few days to a couple of weeks, depending on the complexity and customization.

8. What is the maintenance requirement for the SMT machine?

Regular maintenance is necessary to ensure optimal performance, which includes cleaning, calibrating, and inspecting parts. It is recommended to follow the manufacturer's guidelines for maintenance schedules.

9. Does the production line come with a warranty?

Yes, the production line typically comes with a warranty that covers manufacturing defects and certain components for a specified period. Please check with the manufacturer for specific warranty details.

10. What is the expected lifespan of the SMT machine?

With proper maintenance, the SMT machine can last several years, often exceeding a decade, depending on usage and operating conditions.

11. What training is provided for operators of the SMT production line?

Training is usually provided by the manufacturer, covering operation, maintenance, and troubleshooting of the SMT production line to ensure efficient use and safety.

12. Can the SMT production line handle different sizes of PCBs?

Yes, the SMT production line can be adjusted to accommodate various sizes of PCBs, depending on the specific machine configuration you select.

13. What is the energy consumption of the entire production line?

Energy consumption varies based on the specific components and configurations of the production line. It is advisable to consult the manufacturer for detailed energy efficiency ratings.

14. Are there any specific software requirements for the SMT machine?

Yes, the SMT machine typically requires specific software for operation, which is usually provided with the machine. Compatibility with existing systems should be checked prior to purchase.

15. How can I get technical support for the SMT production line?

Technical support is generally available from the manufacturer, which may include online assistance, phone support, and on-site service options depending on the warranty and service agreement.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading