B21, China Town Mall, Midrand

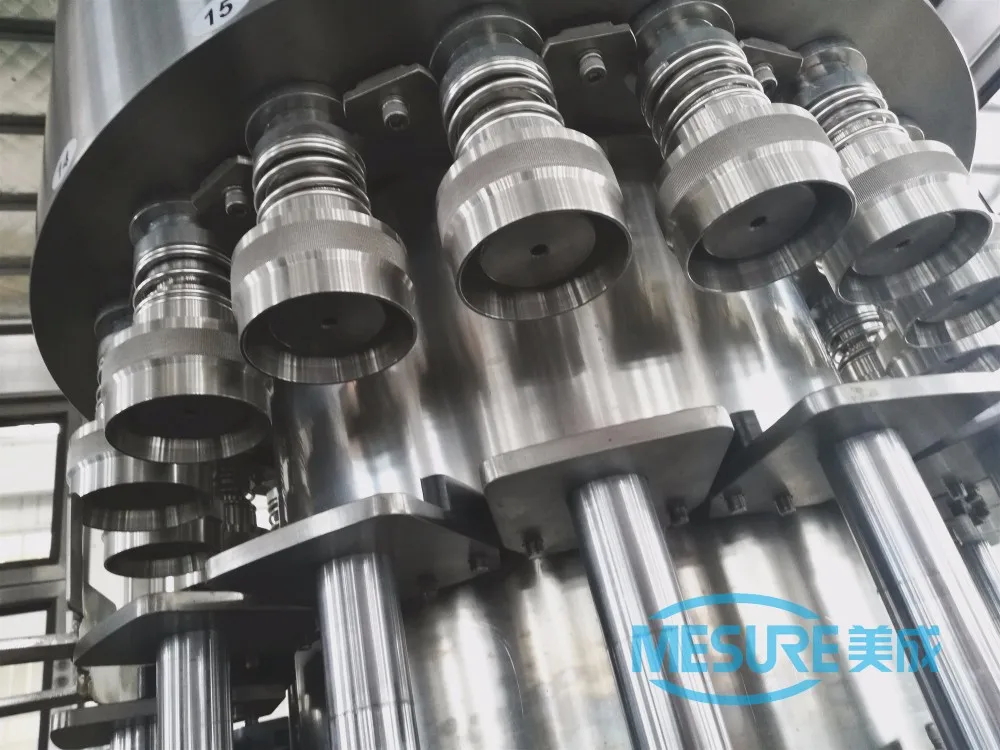

Automatic Spray Can / Gas / Aerosol Can Carbonated Soft Drink Filling Machines Production Line

- Section : Machinery

- Category : Industrial Machinery

- SKU : 62336680811

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 26 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of cans can this filling machine accommodate?

The machine can accommodate cans ranging from 200 to 600ml, with customization options available to suit specific production requirements.

2. What is the filling accuracy of the machine?

The machine achieves an impressive filling accuracy of 99.9%, ensuring precise and reliable results for each can.

3. Is the filling process automated?

Yes, the filling process is fully automated, which ensures consistency, reduces labor costs, and maintains high efficiency.

4. What materials is the machine made from?

The machine is constructed with high-quality Stainless Steel 304/316, ensuring durability and easy maintenance.

5. How many filling heads does the machine have?

The filling head configuration ranges from 6 to 32 heads, providing flexibility based on your production needs.

6. What is the production capacity of the machine?

The production capacity can range from 1500 to 27000 cans per hour, adjustable based on the specific model you choose.

7. What control system does the machine use?

The machine features an advanced PLC control system with a user-friendly touch screen interface for easy operation and monitoring.

8. Does the machine come with after-sales support?

Yes, comprehensive after-sales support is provided, including video technical support, field installation, commissioning, online support, and free spare parts.

9. Can the machine fill non-carbonated beverages?

While the machine is specifically designed for carbonated soft drinks, it can also be utilized for filling energy drinks and juices.

10. What kind of energy-saving features does the machine have?

The machine is engineered for energy efficiency, helping to reduce operational costs while maintaining peak performance.

11. Is a workshop layout design included with the purchase?

Yes, a free workshop layout design is offered to ensure optimal space utilization and workflow.

12. What brands are used for the electrical components?

The machine utilizes world-famous brands for its electrical components, including MITSUBISHI, SIEMENS, and SCHNEIDER.

13. How does the rinsing process work for empty cans?

Empty cans are sent to a turning device, then transferred into a rinsing machine where they are cleaned with 80℃ hot water to reach an aseptic state.

14. What is the overall weight of the machine?

The weight of the machine varies by model, ranging from 2500kg to 9000kg.

15. What are the dimensions of the machine?

The dimensions vary by model, ranging from 1850x1240x1900mm to 4600x2400x1900mm.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading