B21, China Town Mall, Midrand

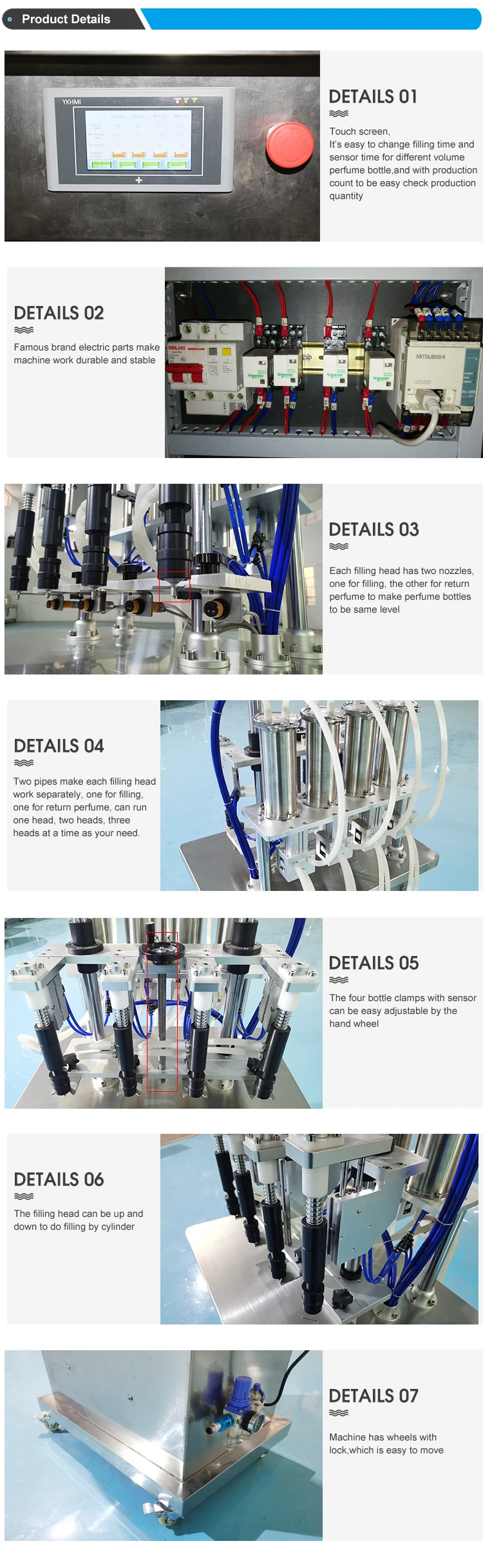

Automatic Filling Machine Production Equipment Machinery

- Section : Machinery

- Category : Filling Machines

- SKU : 1600332637234

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this machine used for?

This Automatic Filling Machine is designed for accurately filling perfume and other low-to-medium viscosity liquids into bottles or containers in a production setting.

2. What are the machine dimensions and footprint?

Overall dimensions are approximately 790 mm (L) × 510 mm (W) × 1680 mm (H). Allow extra space around the machine for operator access, maintenance and material handling.

3. What power supply does the machine require?

The machine accepts single-phase power and is available for 220 V or 110 V configurations. Confirm required voltage when ordering.

4. What filling accuracy and consistency can I expect?

The machine is engineered for precise metering to deliver consistent fills suitable for perfume. Actual accuracy depends on the filling head type and calibration; consult the supplier for measured accuracy for your product.

5. What production speed does the machine achieve?

Output depends on product properties, container size and configuration. Production speed varies by model and setup—contact the manufacturer with your target container and volume for an estimated bottles-per-minute rate.

6. What bottle types and sizes are compatible?

The machine supports a range of bottle sizes and shapes commonly used for perfumes. Changeover for different containers is possible; provide specific bottle dimensions so the supplier can confirm compatibility or recommend fixtures.

7. Can it handle different perfume viscosities and formulations?

Yes. The machine is intended for perfumes and other low-to-medium viscosity liquids. For thicker formulations or suspensions, confirm compatibility and recommended pump/nozzle options with the supplier.

8. What filling method does the machine use?

Filling method may vary by unit (e.g., piston, pump or peristaltic metering). The supplier can specify the exact metering system used on the model you purchase and recommend the best option for perfume.

9. How easy is product changeover and cleaning?

The machine is designed for routine cleaning and product changeovers. Some configurations support simplified disassembly and optional CIP (clean-in-place) features; request details based on your hygiene requirements.

10. What materials are used in product-contact parts?

Product-contact components are typically stainless steel (often 304 or 316) and inert materials suitable for perfumes. Confirm exact materials if you have specific compatibility or regulatory needs.

11. What maintenance is required?

Regular maintenance includes cleaning, inspection of seals and hoses, periodic lubrication of mechanical parts and calibration checks. The supplier can provide a recommended maintenance schedule and a spare-parts list.

12. Are spare parts and technical support available?

Yes. Manufacturers typically supply spare parts, consumables and technical support. Ask about lead times for common wear parts and options for service or remote support.

13. What certifications and quality standards does the machine meet?

Certification availability (CE, ISO, etc.) varies by manufacturer and configuration. Request certificates and documentation from the supplier to meet your regulatory and quality requirements.

14. Is installation, commissioning and operator training provided?

Many suppliers offer installation, commissioning and operator/maintenance training either onsite or remotely. Confirm what's included in your purchase or available as an add-on service.

15. What warranty and shipping/packaging options are offered?

Warranty terms and shipping/packaging options vary by manufacturer. Commonly a limited warranty is provided and machines are shipped in protective crates. Confirm warranty length, coverage and shipping method with the supplier before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading