B21, China Town Mall, Midrand

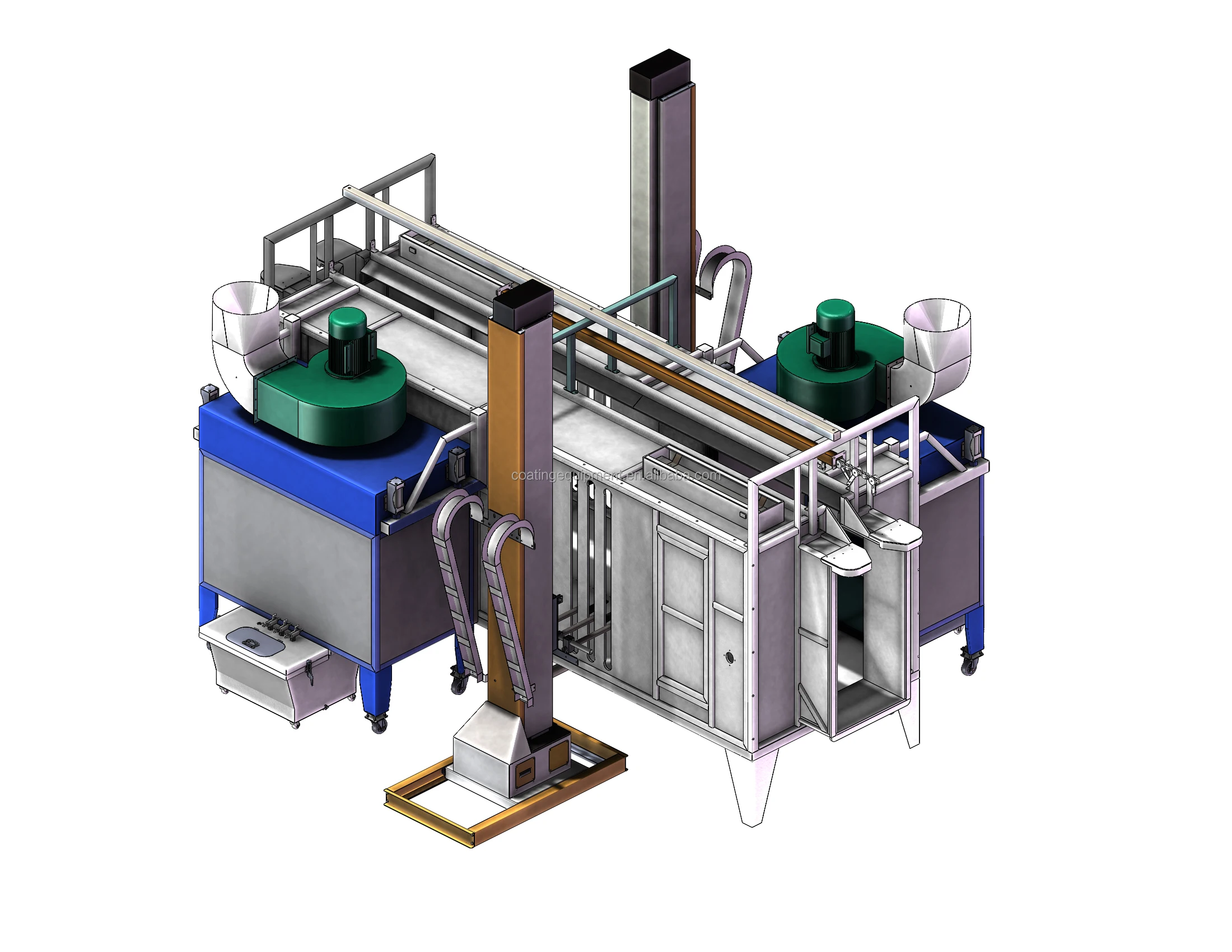

Automatic Electrostatic Powder Coating Line

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600260490652

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is an Automatic Electrostatic Powder Coating Line?

An automatic electrostatic powder coating line is a production system that applies dry powder paint to metal (and some non-metal) parts using electrostatic charge, then cures the coating in an oven. It combines pretreatment, powder application, recovery, conveyor transport and curing into a continuous or semi-continuous workflow for consistent, high-quality finishes.

2. What components are included in your turnkey powder coating solution?

Typical components are a pretreatment system (dip tank or spray), conveyor/transfer system (manual or fully automatic, ground rail if required), electrostatic powder spray booths and guns, powder recovery system (cyclone + secondary filter or simple filter), curing oven (tunnel, bridge or box), control cabinets, and all necessary piping, fixtures and 3D assembly drawings.

3. How do you decide between manual delivery and automatic conveyor systems?

We analyze the customer's budget, production capacity, workpiece weight, size, shape and handling needs. Manual delivery is cost-effective for low-volume or large/irregular parts; fully automatic conveyors are chosen for higher throughput, consistent cycle times and smaller standardized parts.

4. What is a ground rail mode and when is it recommended?

Ground rail mode uses floor-mounted rails to transport heavy or bulky parts reliably. It is recommended when workpieces are large, heavy, or oddly shaped and when a robust, low-maintenance transport method with flexible run length is required.

5. What pretreatment options do you offer and why are they important?

We offer dip tank (immersion) and spray pretreatment systems. Pretreatment removes oils, rust and contaminants and activates the surface to improve powder adhesion, corrosion resistance and coating longevity. Choice depends on part geometry, throughput and environmental requirements.

6. What powder recovery systems are available and how do they differ?

Options include a cyclone with secondary filter recovery for high-efficiency reclaim and minimal dust emissions, or a simpler filter recovery for lower-cost installations. Cyclone systems recover more overspray and are best for frequent color changes and higher material savings.

7. Which types of curing ovens do you supply?

We supply tunnel ovens for continuous throughput, bridge ovens for medium throughput or special layouts, and box ovens for batch or large single-piece curing. Selection depends on line layout, part heat tolerance and production rate.

8. Can the line be customized to fit my workshop space and product dimensions?

Yes. We design the whole line to minimize workshop footprint and adapt transport routes and oven lengths to your part sizes and production flow. All details are confirmed with client-provided specifications and 3D assembly drawings are provided to aid installation.

9. Do you test and assemble the line before shipment?

Yes. The line is assembled and tested at our facility before delivery. Clients are welcome to visit for inspection and witnessing of tests. We also provide 3D drawings and coordinated delivery schedules to ensure timely installation.

10. How long does it take to change colors and how is fast color change achieved?

Color change time depends on the recovery system and booth layout. Systems with efficient cyclone recovery, dedicated color change procedures and proper booth design can achieve fast color changes by minimizing residual powder and enabling quick cleaning cycles.

11. What maintenance is required and what are typical operating costs?

Routine maintenance includes cleaning and replacing filters, checking powder guns and hoppers, inspecting conveyors and oven elements, and periodic calibration of controls. Operating costs include powder material, energy for ovens and conveyors, consumables (filters, nozzles) and occasional spare parts. We design for low maintenance and provide a recommended maintenance schedule.

12. What environmental and safety features are included?

We provide powder recovery systems and filtration to minimize airborne powder and emissions, enclosed booths to reduce overspray, proper ventilation and explosion-proof electrical components as needed. Safety interlocks, CE/UL-compliant controls and operator training are part of the standard offering.

13. What lead times and delivery arrangements do you offer?

Lead time depends on scope and customization; typical planning, fabrication, testing and delivery schedules are provided after specification confirmation. We arrange shipping and can coordinate installation timelines to meet client requirements, with advance scheduling to ensure on-time delivery.

14. Do you provide installation, commissioning and training?

Yes. We offer on-site installation and commissioning services, pre-shipment assembly guidance via 3D drawings, and operator/maintenance training to ensure safe, efficient operation. Ongoing technical support and spare parts supply are available.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading