B21, China Town Mall, Midrand

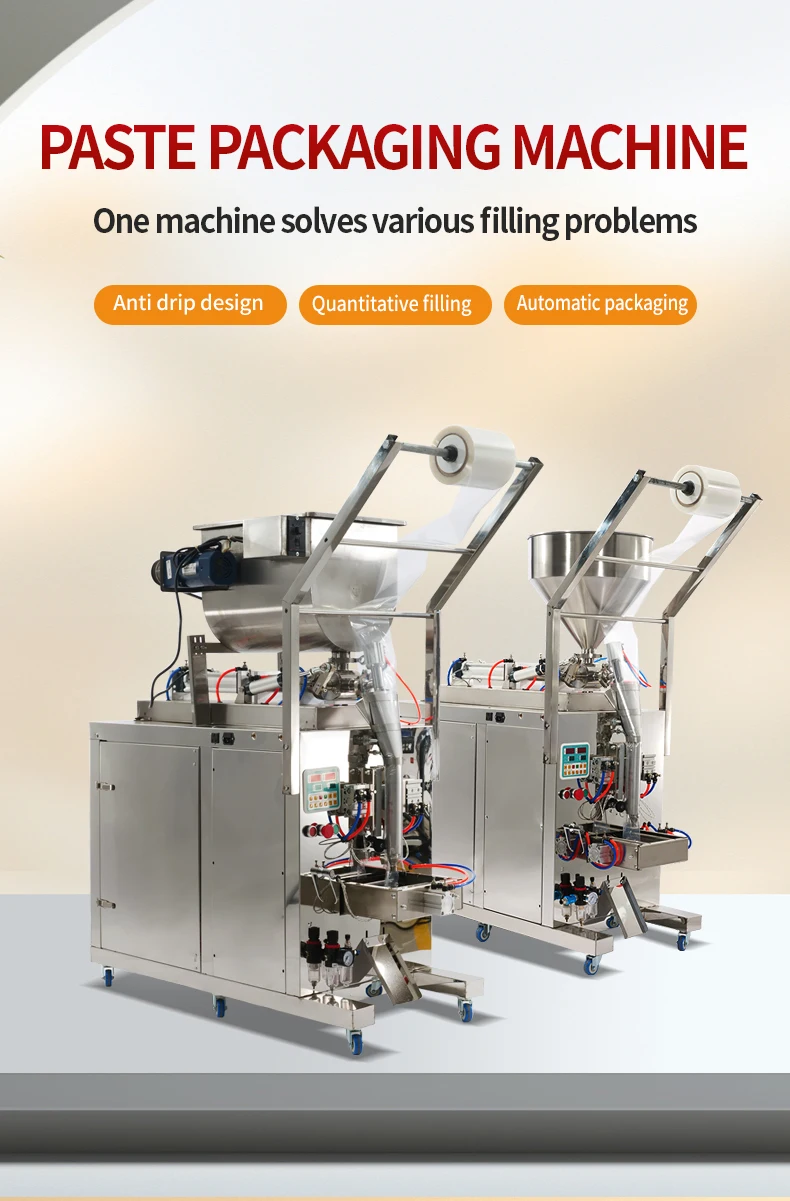

Automatic butter syrup And sealing tomato paste packaging machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600336832832

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products can this Automatic Liquid Paste Filling and Packaging Machine handle?

The machine is designed for a wide range of liquids and pastes, including butter, syrups, tomato paste, honey, sauces, salad dressings, jams, peanut butter, shampoos, creams and other high-viscosity products.

2. Is this machine food-grade and suitable for hygienic production?

Yes. The machine is constructed fully of stainless steel, meeting food safety requirements and providing rust-proof durability for hygienic, food-grade production.

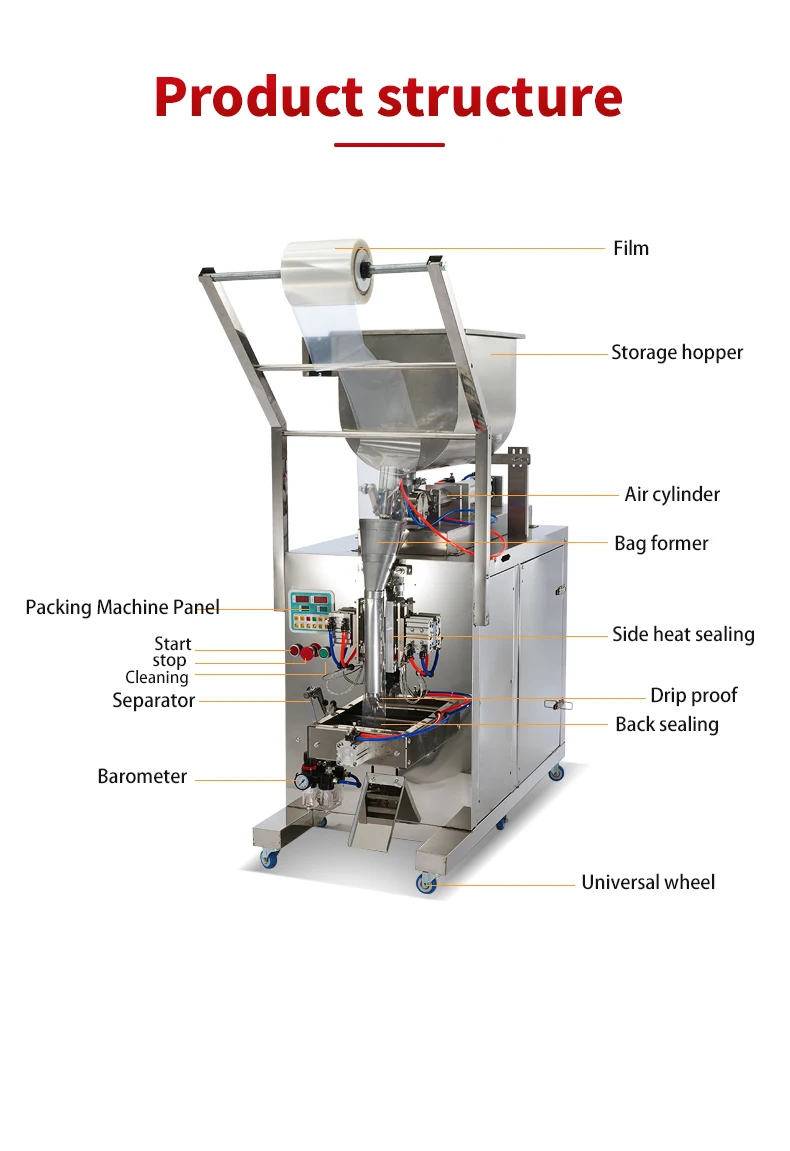

3. How does the machine dose viscous products like tomato paste or butter?

It uses a pneumatic pump dosing unit which is ideal for viscous and paste-like products. The pump provides precise, repeatable fills and handles thicker fluids better than gravity or piston-only systems.

4. What packaging formats and film sizes does the machine support?

The machine forms pouches from roll film. Supported roll film widths are 5.0 cm to 20.0 cm, finished bag widths 2.5 cm to 10.0 cm, and adjustable bag lengths from 0 to 16 cm.

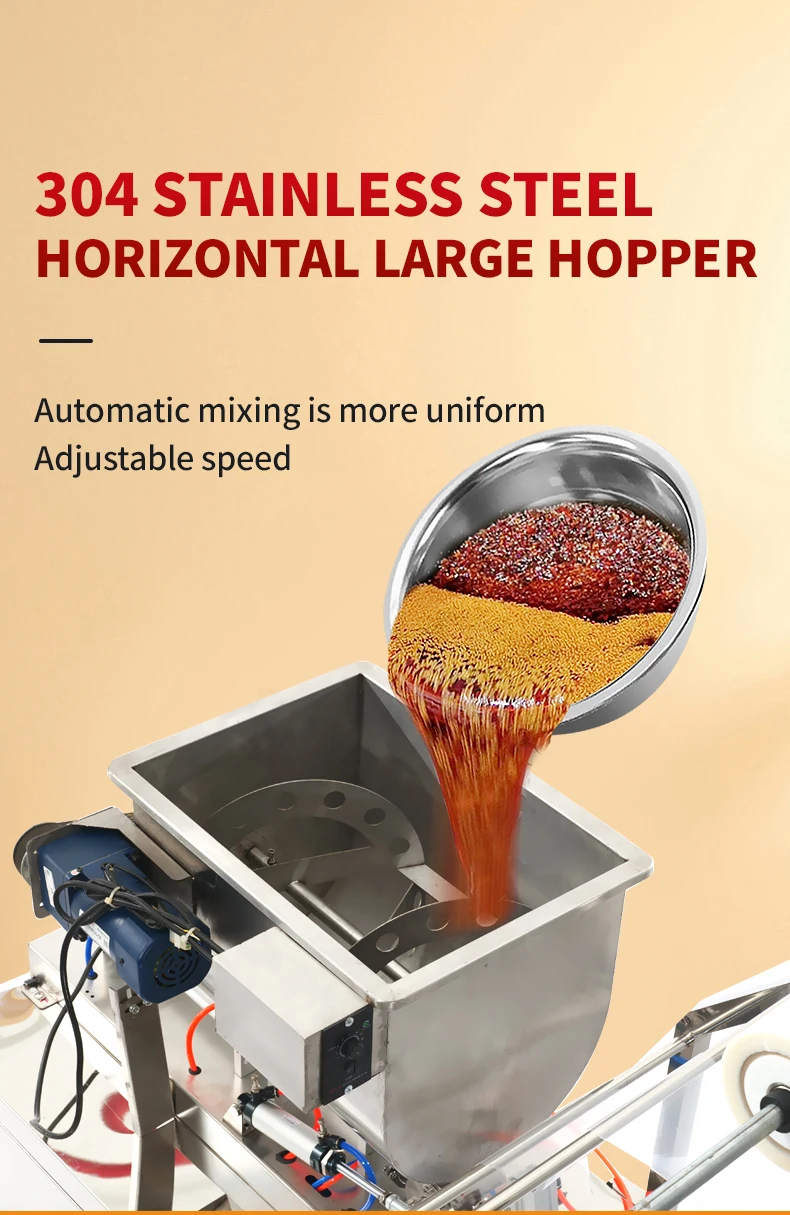

5. Does the machine mix product and prevent settling before filling?

Yes. An integrated small horizontal ribbon blender provides uniform mixing to reduce product deposit and maintain homogeneity prior to filling.

6. What functions are automated?

The machine automates measuring, filling, pouch forming, sealing, and cutting — producing finished pouches with minimal operator intervention.

7. What sealing method does the machine use and are the seals reliable for sauces and pastes?

It uses heat sealing to form and seal pouches. The seals are designed for paste and sauce applications; proper film selection and process settings ensure leak-free, attractive seals.

8. Can the machine handle particulates (e.g., seeds, chunks) in products like salsa?

The machine is best suited for homogeneous, pumpable pastes and sauces. Small particulates may be handled depending on pump and nozzle size; large chunks may require a specialized pump or filler. Consult us with product samples for evaluation.

9. What is the machine's production speed?

Production speed depends on product viscosity, bag size and film type. The machine is high-speed compared with manual filling; please provide product details and desired bag specs so we can offer estimated throughput (bags per minute).

10. What utilities and site requirements are needed (power, air, footprint)?

The machine requires electrical power and a compressed air supply for the pneumatic pump and controls. Exact voltage/phase, air pressure and flow, and machine footprint depend on model/configuration—please contact sales with your local utility specs for precise requirements.

11. How easy is it to clean and maintain the machine?

The stainless steel design simplifies cleaning. Components in contact with product are accessible for disassembly and cleaning. Routine maintenance includes sanitizing contact parts, checking seals, inspecting hoses and pump components, and lubricating moving parts per the maintenance schedule.

12. Can I run different bag sizes or changeover between products quickly?

Yes. Bag width and length are adjustable within the machine's supported range. Changeover time depends on film roll change and minor mechanical adjustments; quick-change design principles reduce downtime. We can provide training and guidance to optimize changeovers.

13. Is customization available (nozzles, pumps, control options, material handling)?

Yes. We offer customization such as different pump types or nozzle sizes for specific viscosities/particulates, electronic control options, integration with upstream mixers or conveyors, and alternative sealing heads or film-handling options. Discuss your product and line requirements for a tailored solution.

14. Do you offer testing, samples or trial runs with our product before purchase?

Yes. We recommend running trials with your product so we can confirm fill accuracy, seal integrity and throughput. Provide product samples and desired pouch specs and we will perform tests and share results.

15. What after-sales support, spare parts and warranty do you provide?

We provide technical support, operator training, recommended spare parts lists and warranty terms. Specific warranty duration and support packages depend on the model and purchase agreement—please request details when inquiring.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading