B21, China Town Mall, Midrand

Agricultural Feed Silo

- Section : Machinery

- Category : Other Agricultural Equipment

- SKU : 1600266701966

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials are used in the construction of the Agricultural Feed Silo?

The Agricultural Feed Silo is made from 275g/㎡ hot-dip galvanized steel, which offers excellent corrosion resistance and durability.

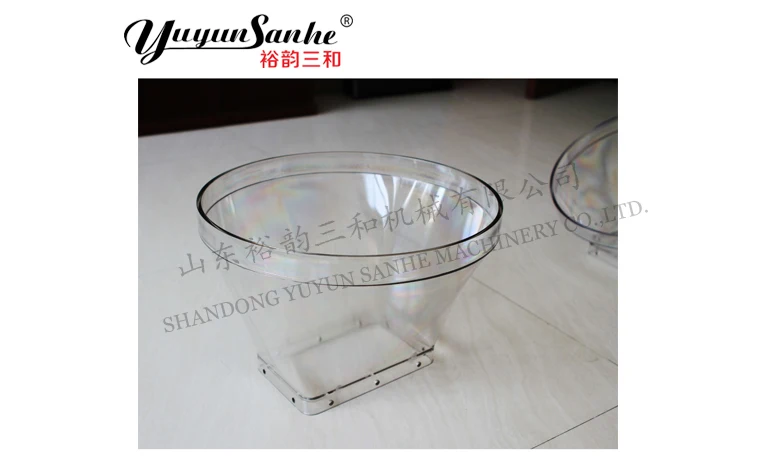

2. How can I monitor the feed levels in the silo?

The silo is equipped with an observation window made from plastic injection molding, allowing for easy monitoring of feed storage levels.

3. Is the silo resistant to harsh weather conditions?

Yes, the silo is designed to withstand strong storms and harsh weather conditions due to its durable and high-strength construction.

4. How is the silo assembled?

The silo features precision-cut components for easy assembly, making the installation process convenient.

5. What safety features does the silo include?

The silo includes a mounting ladder with a security cage for safe access and maintenance.

6. Can the silo prevent feed mold growth?

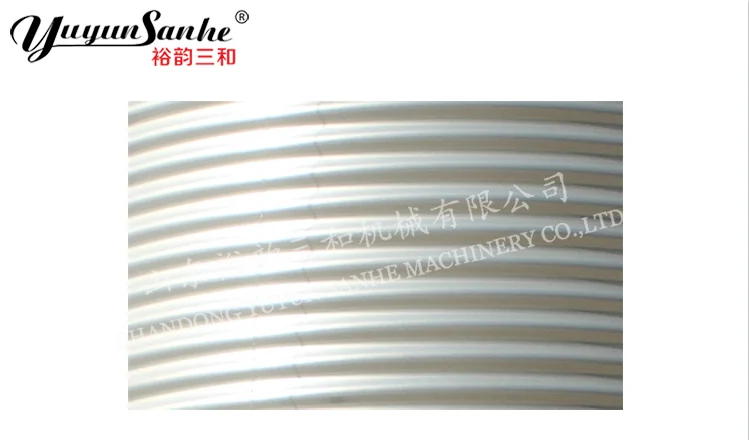

Yes, the corrugated design of the silo ring sheets reduces condensation inside the silo, helping to prevent mold growth and maintain feed quality.

7. What are the available capacities for the Agricultural Feed Silo?

The silo comes in various models with capacities ranging from 2.5 tons to 27.9 tons, depending on the specific model chosen.

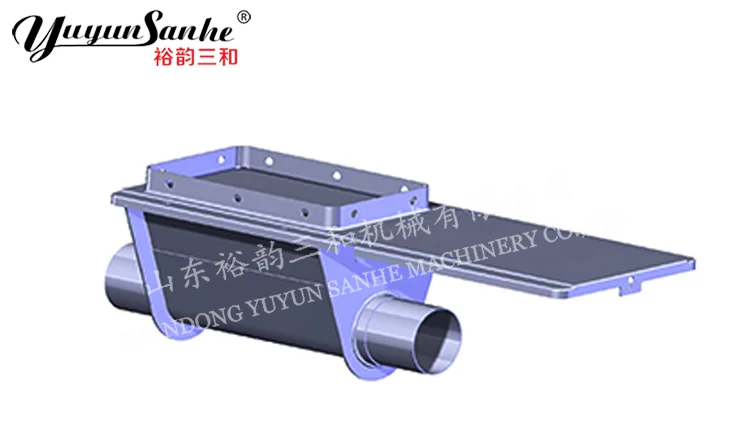

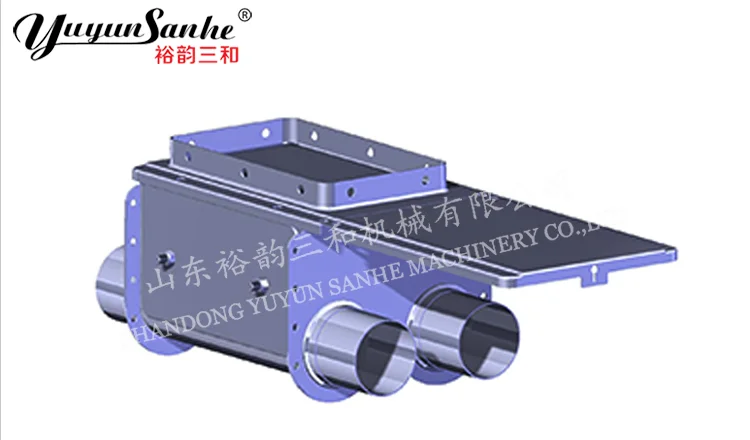

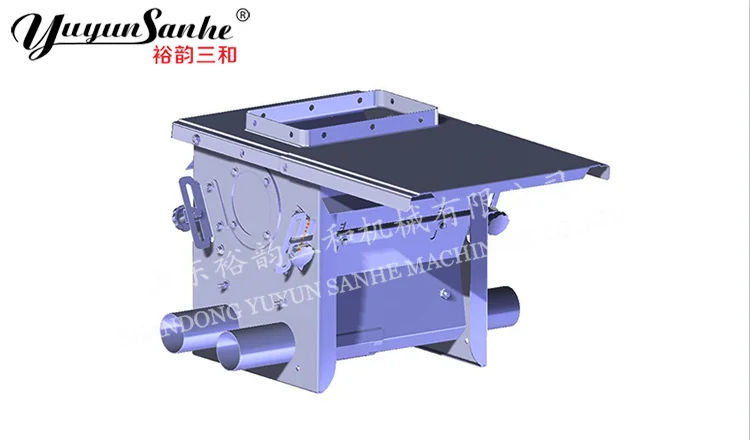

8. Are there optional parts available for the silo?

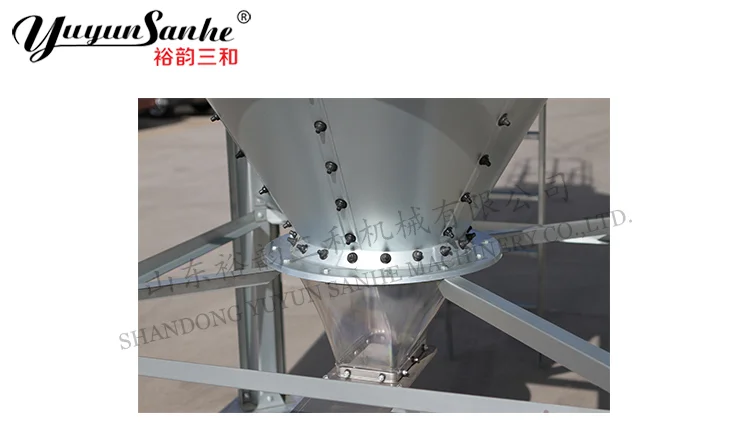

Yes, optional parts include auger hoppers for feed transportation, plug hoppers with single or double exits, and different configurations for complex feed conveyor needs.

9. What certifications does Yuyun Sanhe Company hold?

Yuyun Sanhe Company has achieved multiple certifications, including CE Certificate, CCC Certificate, and Quality Management System Certificate.

10. How does the air duct in the silo function?

The air duct helps balance air pressure inside and outside the silo, discharging gases and heat for smooth feeding and cleanliness.

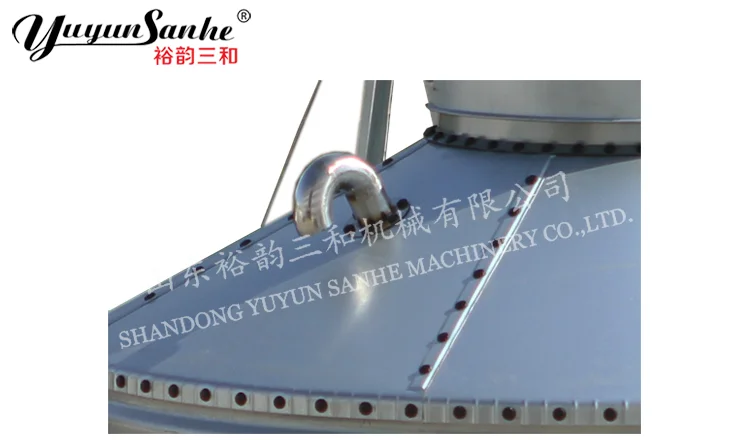

11. What type of bolts are used in the silo construction?

The silo is secured with 8.8-grade high-strength hot-dip galvanized bolts, which ensure durability and rust prevention.

12. Is the silo suitable for all types of animal feed?

Yes, the Agricultural Feed Silo is ideal for storing various types of animal feed, keeping it fresh and free from contamination.

13. How does the smooth inner wall of the silo benefit feeding?

The smooth inner walls facilitate efficient feeding and reduce feed accumulation, improving overall feed management.

14. What is the height of the silo?

The height of the silo varies by model, ranging from 4.8 meters to 8.5 meters, depending on the specific silo chosen.

15. Can the silo be customized for specific needs?

Yes, the silo can be customized with various optional parts to meet specific feed storage and transportation requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading