B21, China Town Mall, Midrand

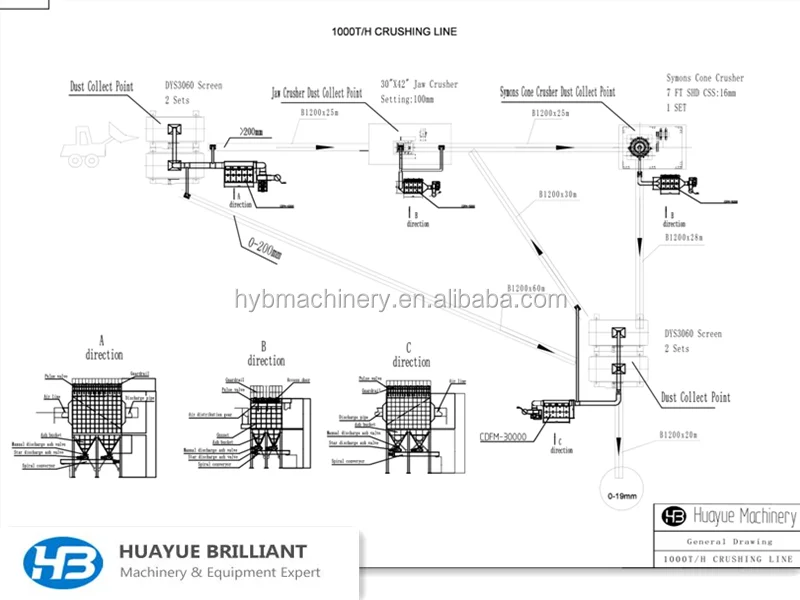

Aggregate Processing Plant Mining Machinery Quarry Crushing Line Stone Ore Rock Granite Limestone Crusher Plant

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600536159383

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 29 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is included in the Aggregate Processing Plant?

The Aggregate Processing Plant includes a Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyor, and Control System.

2. What types of materials can this plant crush?

The plant is capable of crushing limestone, marble, granite, basalt, river gravel, and other hard stone materials.

3. What is the production capacity range for this plant?

We can design and manufacture complete crusher plants with capacities ranging from 30tph to 500tph.

4. How does the crushing process work?

Large stone materials are fed into the jaw crusher for primary crushing, then transported to a cone or impact crusher for fine crushing, and finally separated by a vibrating screen.

5. Is the plant automatic?

Yes, the plant features a high degree of automatic operation, requiring minimal manual intervention aside from starting, stopping, and routine maintenance.

6. What are the benefits of using this crushing plant?

Benefits include high productivity, low investment, regular end product granularity, good grain shape, and low powder output.

7. Can the plant be customized based on my requirements?

Yes, we can provide optimum and economical solutions based on your specific requirements regarding stone specifications, output, and application.

8. What safety features are included in the plant?

The plant incorporates a high advanced control system to ensure security and reliable operation throughout the production line.

9. Are there environmental protection features available?

Yes, the plant can be equipped with dust removing facilities to protect the environment as per customer requests.

10. What types of control systems are available?

The plant uses advanced control systems that ensure security and reliable operation of the entire production line.

11. What is the role of the vibrating feeder in the process?

The vibrating feeder evenly and continuously feeds large stone materials into the jaw crusher for primary crushing.

12. What happens to oversized materials?

Oversized materials are returned to the cone or impact crusher for re-crushing to achieve the desired size.

13. How are the end products sorted?

After crushing, materials are transported to a vibrating screen where they are separated into different sizes.

14. What are the dimensions of the conveyor belts included?

The plant includes various conveyor belts, including 800mmx30m, 800mmx25m, 500mmx15m, and 650mmx30m, all with dust covers.

15. Is routine maintenance required for the plant?

Yes, routine maintenance is necessary to ensure optimal performance, although most operations are automated.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading