B21, China Town Mall, Midrand

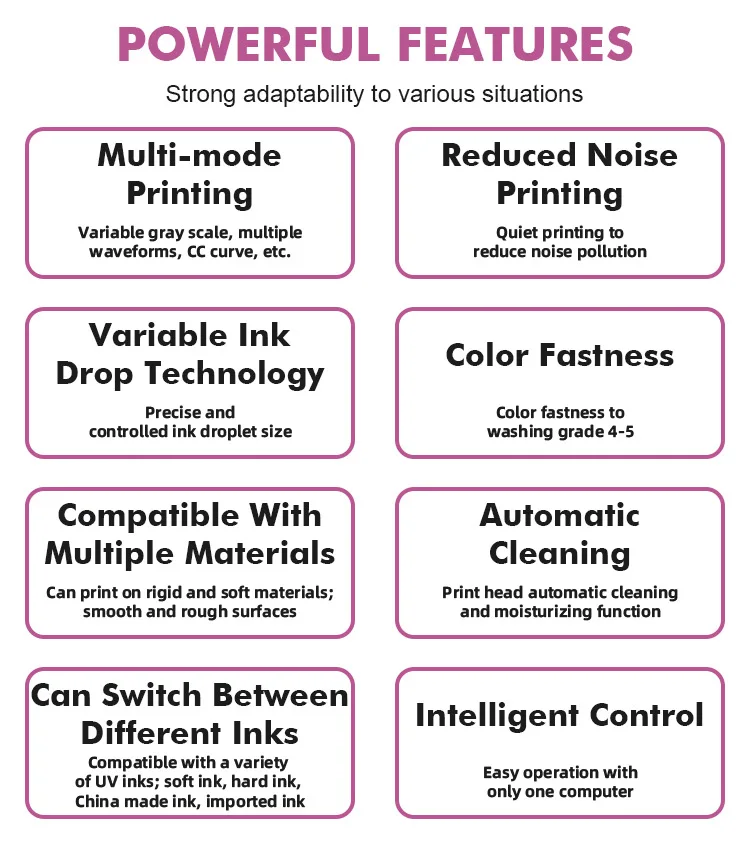

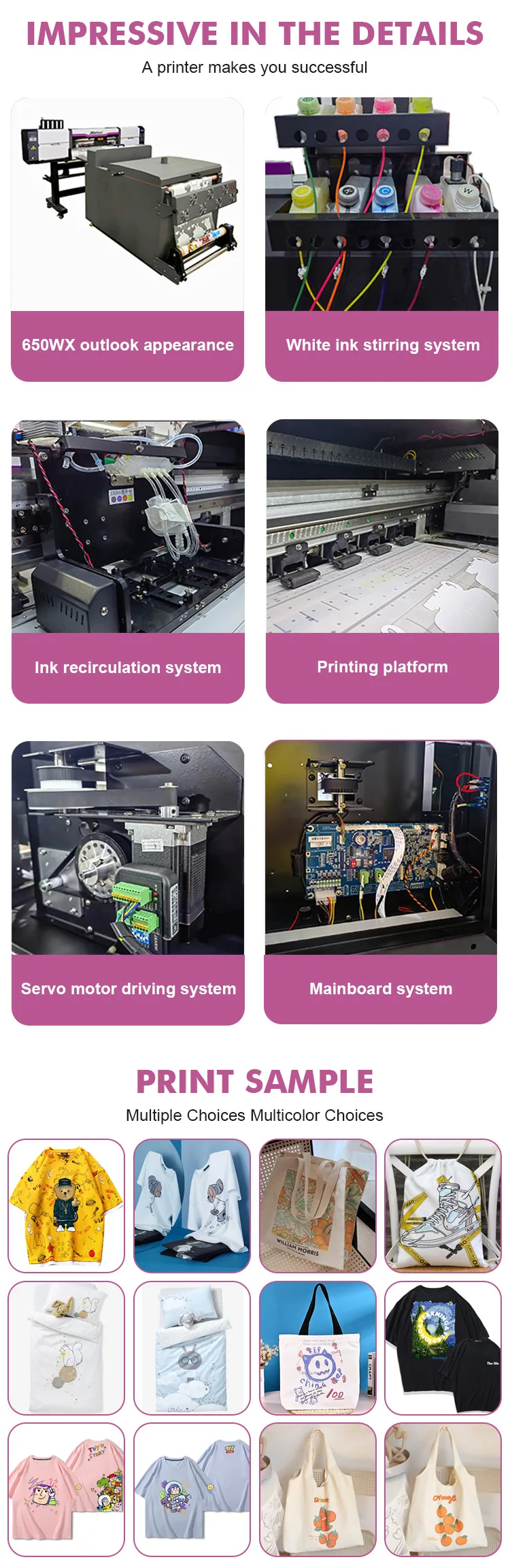

60cm i3200 A1 DTF Printer for Textiles and Labels

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600566565898

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum print width of the 60cm i3200 A1 DTF Printer?

The printer supports a maximum print width of 650 mm, suitable for larger textile panels and label work.

2. Which printhead configurations are available?

The i3200 A1 is available with either 2 or 4 Epson i3200 printheads, letting you choose higher throughput (4-head) or lower cost/entry (2-head) configurations.

3. What print resolution and image quality can I expect?

The machine produces high-quality output up to 1440 dpi, delivering detailed, vibrant designs suitable for garments, labels and graphics.

4. What are the print speeds for the 2-head and 4-head models?

2-head (Epson i3200×2): 6-pass ≈ 12 sqm/h, 8-pass ≈ 8 sqm/h. 4-head (Epson i3200×4): 6-pass ≈ 22 sqm/h, 8-pass ≈ 15 sqm/h. Actual throughput depends on RIP settings, media and environmental conditions.

5. What kind of ink and color set does the printer use?

It uses pigment-based DTF inks configured as CMYK plus White (CMYK+W), formulated for durability and good wash resistance when properly cured and transferred.

6. What substrates and applications is this DTF printer suitable for?

Designed for DTF workflows: prints onto PET transfer film which is then powdered and transferred to textiles (cotton, polyester, blends), leather, nylon and many other fabrics and flexible substrates. It also supports label production when using compatible film and adhesives.

7. Which RIP and software packages are supported?

The printer is compatible with professional RIP and color management tools including Maintop 6.1, PhotoPrint (PP) and PrintFactory (PF). These support common file formats and white-underbase workflows for DTF.

8. What are the recommended operating temperature and humidity ranges?

Recommended operating conditions are 18–29 °C and 50%–80% relative humidity for optimal ink performance and print stability.

9. What are the electrical requirements?

The printer supports 110 V or 220 V power supplies. Confirm the specific unit configuration and local electrical requirements with the supplier or installer before purchase.

10. What are the printer dimensions and weight? Are there packing dimensions?

Dimensions and weights vary by configuration. Typical packed machine dimensions are about 1920×760×1300 mm. Example component weights listed for some configurations: printer ≈ 204 kg and powder shaking machine ≈ 300 kg. (Some spec sheets also list other figures such as 1560×750×1500 mm and ~140 kg—please confirm the exact model spec with the seller.)

11. What is the typical DTF production workflow with this machine?

Typical workflow: prepare artwork in RIP → print mirror image onto PET transfer film → apply hot-melt powder to the wet print → use the powder shaker to remove excess powder → optionally pre-cure or dry the ink/powder → transfer to garment using a heat press or heat-transfer tunnel and finish with recommended press temperature/pressure/time for the media.

12. How should I maintain the white ink system and printheads?

DTF white ink requires regular circulation and cleaning to prevent sedimentation. Implement daily or per-shift white-ink circulation routines, perform scheduled head cleanings per the manual, and use manufacturer-approved cleaning solutions. Follow the supplied maintenance guide for nozzle checks and preventative care.

13. What consumables and spare parts will I need regularly?

Typical consumables include pigment DTF inks (CMYK+W), PET transfer film, hot-melt powder, wiper/cleaning kits, maintenance cartridges, and occasionally replacement printheads or pumps. Stock critical items like powder and white ink to avoid production downtime.

14. Is installation, training and warranty included?

Installation, training and warranty terms vary by vendor. Many suppliers offer onsite setup, operator training and a limited warranty/support package—confirm details, service levels and response times with your reseller before purchase.

15. Can I use third-party inks, films and powders with this printer?

Third-party consumables may work, but color accuracy, adhesion and long-term reliability can vary. For best results and warranty compliance, use supplier-recommended or manufacturer-approved inks, films and powders and validate any third-party materials before large production runs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading