B21, China Town Mall, Midrand

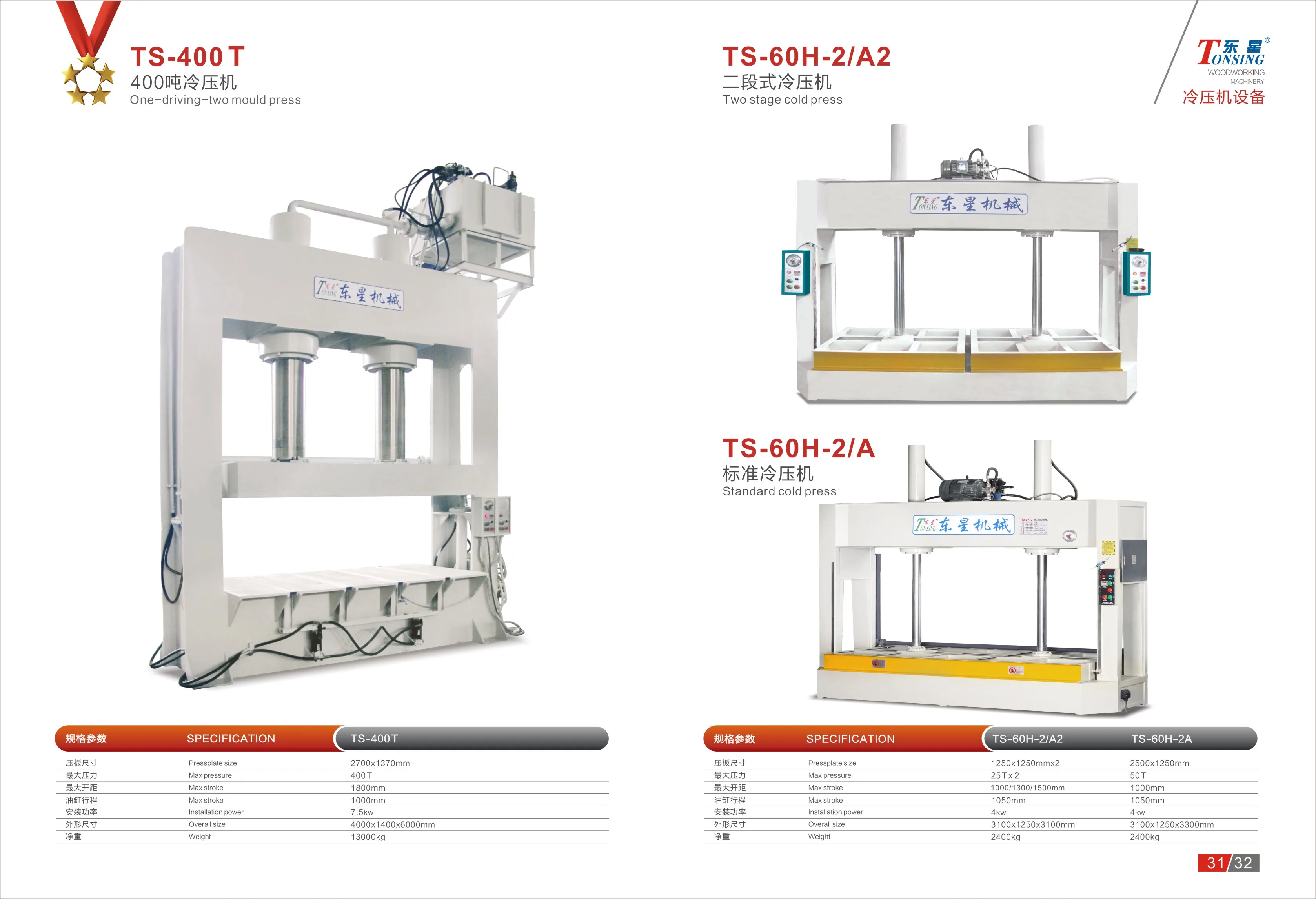

400T Hydraulic Cold Press Machine Furniture door Cold Press Machine Plywood Cold Press Machine

- Section : Machinery

- Category : Woodworking Machinery

- SKU : 1601000869688

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 400T Hydraulic Cold Press Machine used for?

It's used for laminating, veneering and bonding operations in woodworking and furniture production — for MDF, plywood, veneer, furniture doors, sound boxes, upholstery, advertising boards, plastic sheets, shaving boards and other laminated or veneered panels.

2. What does 'cold press' mean and how does this machine bond materials?

A cold press applies hydraulic pressure (without heating the platen) to hold parts together while adhesive cures. The machine provides controlled pressure and timing so adhesives set under consistent pressure and flatness.

3. What model options are available?

The product listing refers to model TS-60H-2/A2. A 2-stage cold press configuration is offered as an option. The machine can also be customized for different layer counts, pressures and worktable sizes.

4. What are the key features of this cold press?

Easy operation and reasonable design, stable performance, fast and efficient pressing, emergency safety braking, trip limit device, automatic compression and unloading pressure function, timing and pressure controls, EMG stop button, and ergonomic worktable height.

5. What safety features does the machine include?

Safety features include an emergency stop (EMG) button, emergency safety braking, and a trip limited device to prevent over-travel or unsafe operation.

6. How is the machine controlled (pressure/time)?

The machine includes timing control and pressure control systems and supports automatic compression and pressure unloading functions to simplify repetitive pressing cycles.

7. Can the machine be customized for different product sizes and layer counts?

Yes — the manufacturer offers customization of worktable size, number of layers (stages), and maximum pressure to match specific production requirements.

8. What are the electrical and installation requirements?

Exact electrical supply, foundation and installation requirements depend on the configured model and options. The supplier will provide detailed specifications and installation guidance with the order; onsite installation support is often available.

9. What maintenance is required to keep the press running reliably?

Routine maintenance includes checking and topping hydraulic fluid, inspecting seals and hoses, tightening fasteners, keeping platen and table surfaces clean, checking safety devices, and following the manufacturer's scheduled service instructions.

10. What is the typical cycle time for pressing?

Cycle time depends primarily on the adhesive, substrate and product design. The manufacturer can provide recommended pressing times for common adhesives and applications; typical times can range from minutes to hours depending on the bonding method.

11. What are the machine's capacity and maximum pressure (400T reference)?

The '400T' designation commonly indicates a press capacity class, but exact maximum working pressure and platen load depend on the configured hydraulic system. Ask the supplier for the specification sheet for exact capacity and rated working pressure.

12. Do you provide operator training and user manuals?

Yes. The supplier typically provides operator manuals, and training can be arranged to cover safe operation, routine maintenance and troubleshooting — either at the factory or on site, depending on the purchase agreement.

13. Are spare parts and after-sales support available?

Spare parts and after-sales support are available from the manufacturer or authorized dealer. Contact the seller for details on warranty, spare parts kits and service packages.

14. How do I get a quote and what is the lead time?

Contact the supplier or dealer with your desired configuration (number of layers, table size, pressure rating, electrical supply). Lead time depends on customization level and current production schedule; the supplier will provide a quote and estimated delivery time.

15. What workspace or footprint considerations should I plan for?

Footprint, weight and required clearances depend on the model and options chosen. In addition to machine size, allow space for material handling, operator access and maintenance. The supplier can provide detailed dimensional drawings once a configuration is selected.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading