B21, China Town Mall, Midrand

3D Vertical UV Wall Printer | VPJet4.0 Wall Painting Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600903817898

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum printable area of the 3D Vertical UV Wall Printer (VPJet4.0 / DXonJet)?

The printer supports prints up to 2500 mm x 6000 mm (width x height), allowing large murals and full-wall graphics.

2. What print resolution and speed does this wall printer offer?

It can print up to 1440 DPI for high-detail output and achieves print speeds up to approximately 3 square meters per hour (actual speed depends on resolution and print mode).

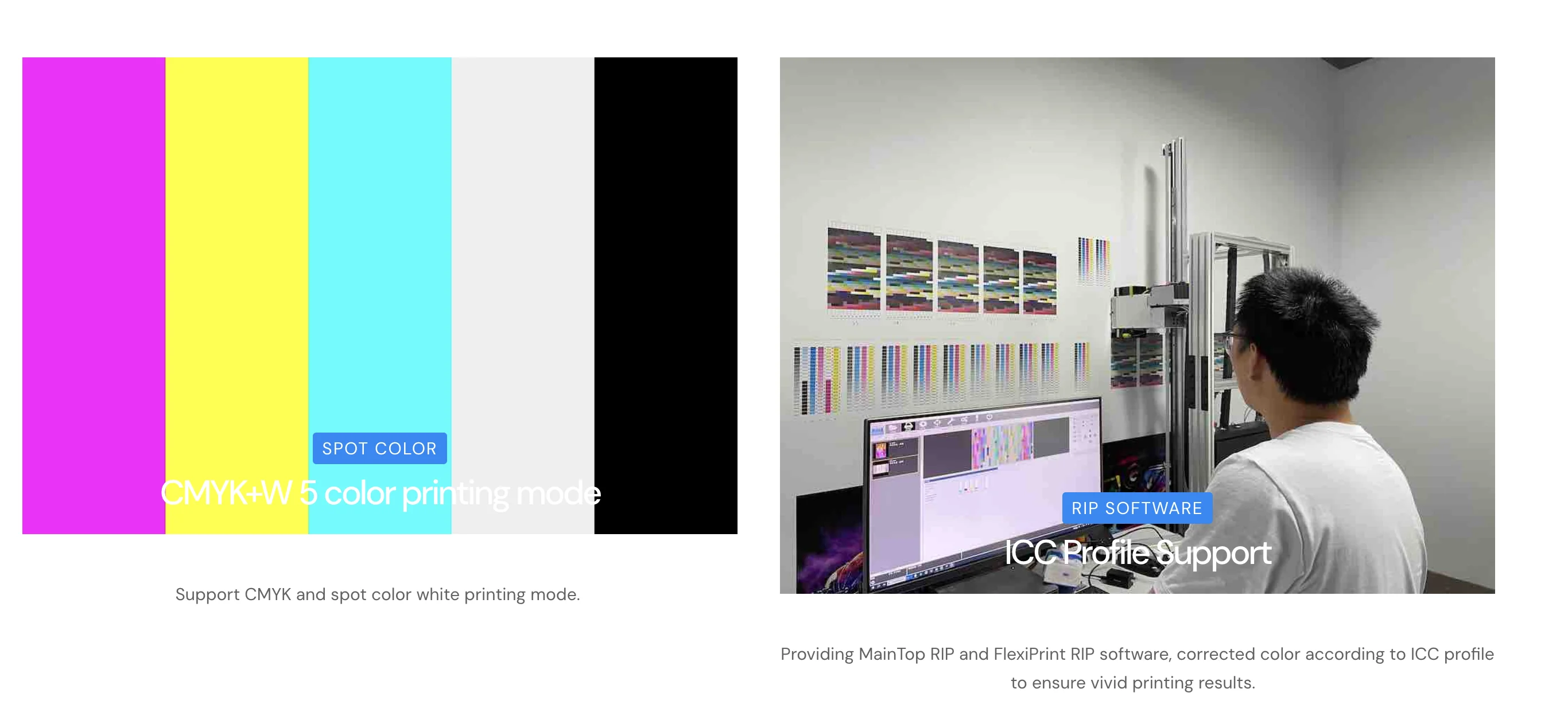

3. Which ink system and colors are used?

The machine uses UV-curable inks with a CMYKWW color configuration (Cyan, Magenta, Yellow, Black, plus two White channels) to produce vibrant colors and strong white/opacity on many substrates.

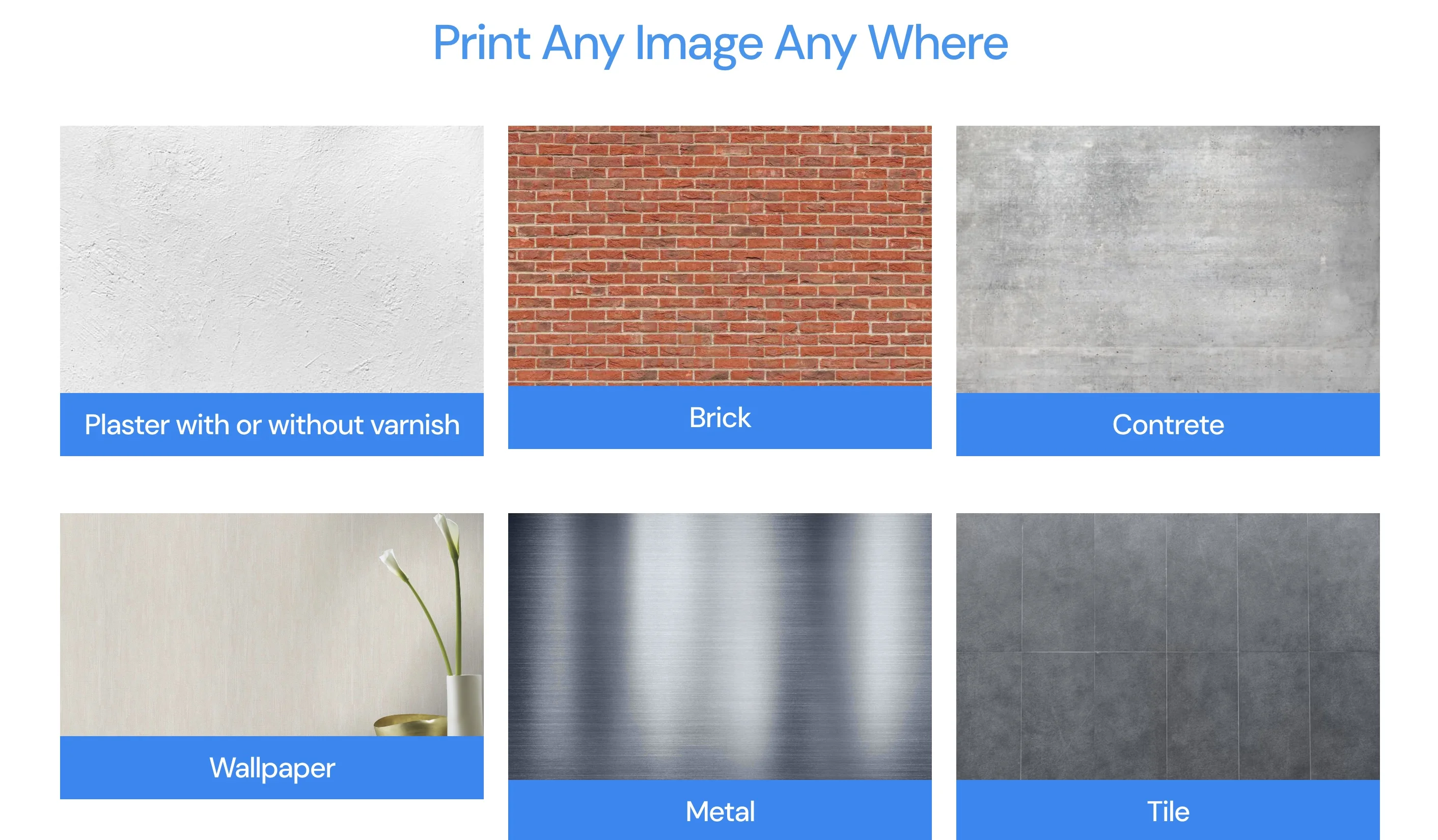

4. What materials can the printer print on?

It is designed to print on many flat substrates including paper, cloth, leather and wallpaper. For non-porous or specialty surfaces, surface preparation or primer may be required to ensure adhesion and durability.

5. Which print head does the printer use?

The unit is equipped with a DX7 print head, a widely used industrial print head known for image quality and reliability.

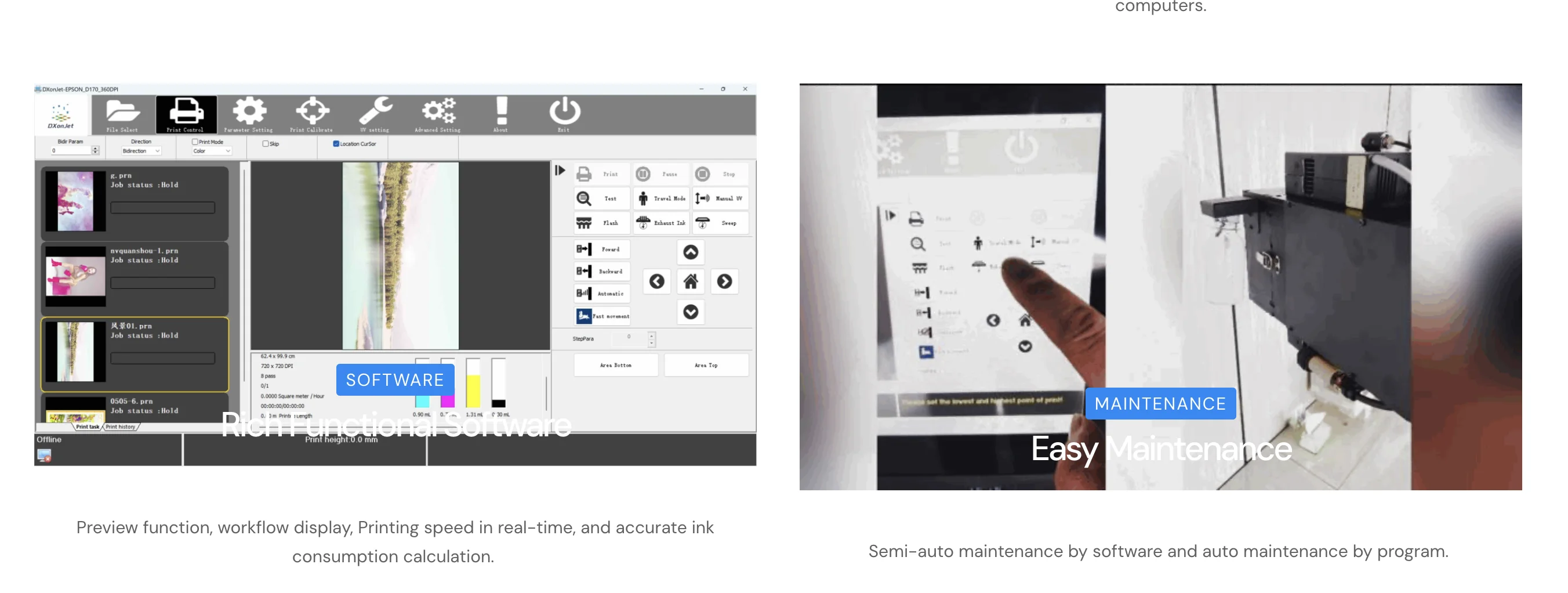

6. What software does the printer use and what file types are supported?

The printer is compatible with Maintop RIP software (main) and PhotoPrint (optional). These RIP packages handle common image formats and workflows (JPEG, TIFF, PDF, etc.) — confirm exact supported formats with your vendor or software manual.

7. Is the printer easy to operate for new users?

Yes. The DXonJet is designed with automatic functions and a user-friendly workflow to suit both experienced operators and beginners. Video technical support is provided; additional instruction can be requested from the vendor.

8. What are the physical dimensions, weight and power requirements?

The printer measures 232 cm x 50 cm x 60 cm (L x W x H), weighs approximately 80 kg, and supports 110 V / 220 V power supplies (confirm required voltage for your region).

9. What warranty and after-sales support are included?

A 1-year warranty is provided for core components. The product comes with a machinery test report and video outgoing inspection; video technical support is available. For on-site service or extended warranties, contact the vendor.

10. What routine maintenance is required?

Routine maintenance includes regular print-head nozzle checks and cleaning, periodic flushing or capping-station care, monitoring ink levels and pumps, and replacing consumables as needed. Using recommended/ genuine inks and maintenance fluids helps maintain performance and longevity.

11. Are printed graphics suitable for outdoor use?

UV inks generally offer good outdoor durability, but longevity depends on substrate, ink, curing quality and environmental exposure. For outdoor installations, use appropriate substrates, consider protective coatings, and verify curing to maximize durability.

12. Does the printer include UV curing, or is additional curing equipment required?

The product uses UV-curable inks. Some units include integrated UV curing, while others may require external curing equipment depending on configuration. Confirm with the seller whether your specific unit includes on-board UV lamps or requires separate curing solutions.

13. What safety and handling precautions should I take when using this wall printer?

Follow the ink manufacturer's MSDS and vendor safety guidance: use gloves and eye protection when handling inks, ensure adequate ventilation when printing/curing, avoid direct skin contact with uncured ink, and dispose of waste per local regulations.

14. Are spare parts and consumables available for this model?

Core components listed include motor, pressure vessel, pump, gear, bearing and gearbox. Spare parts and consumables (ink, maintenance kits, replacement parts) are typically available—contact the vendor for part numbers, pricing and lead times.

15. How can I get pricing, lead time, installation and customization information?

For accurate pricing, lead times, shipping, on-site installation or customization (e.g., custom mountings, integrated UV curing, or software bundles), provide your project details (desired print size, substrates, destination) and contact the vendor or authorized reseller for a formal quote and service options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading