B21, China Town Mall, Midrand

316L Stainless Steel Pump

- Section : Electrical & Tools

- Category : Tools & Hardware

- SKU : 1600212843570-1710145765

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

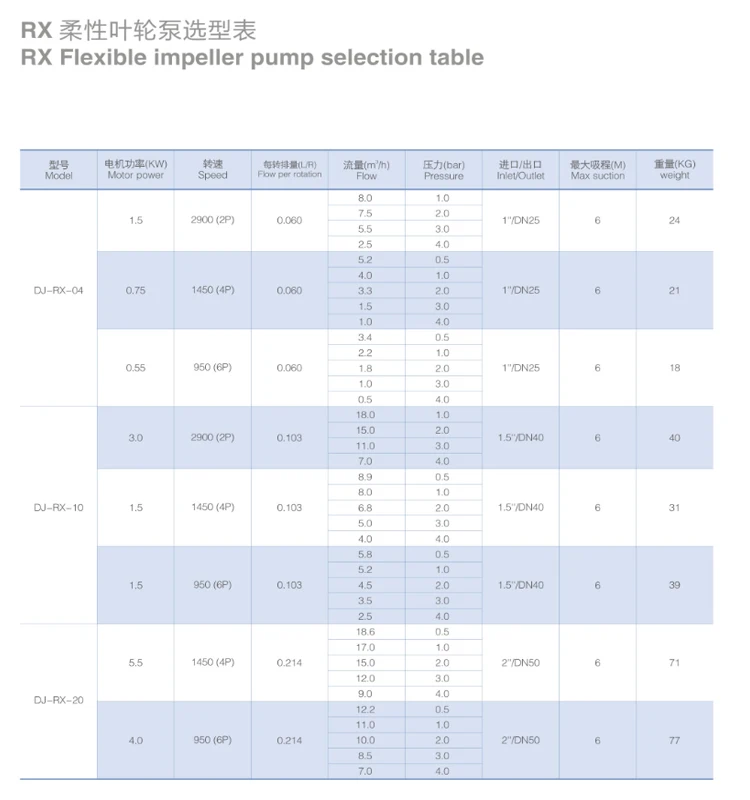

1. What are the pump's maximum operating limits (flow, pressure, suction, temperature, speed)?

Max flow: 20 m³/h; Max pressure: 4 bar; Max suction depth: 6 m; Max temperature: 80 °C; Rotating speed range: 950–2,900 RPM.

2. What material is the pump constructed from and why is that important?

The pump is made from 316L stainless steel. 316L offers excellent corrosion resistance, good mechanical strength, and chemical compatibility for food, pharmaceutical and many chemical applications, increasing longevity and reducing contamination risk.

3. What does the surface finish Ra ≤ 0.6 μm / Ra ≤ 0.4 μm mean and why does it matter?

Ra values indicate average surface roughness. Ra ≤ 0.6 μm and Ra ≤ 0.4 μm are smooth finishes that reduce residue retention, minimize bacterial harborage, improve cleanability and lower wear — important for hygienic and high-purity applications.

4. Which industries and applications is this pump suitable for?

Typical applications include food processing, pharmaceuticals, chemical handling and general industrial fluid transfer where corrosion resistance, hygiene and reliable performance are required.

5. Is the pump suitable for sanitary/CIP/SIP cleaning procedures?

The pump is designed for hygienic applications and its smooth surface finish supports effective cleaning. For validated CIP/SIP cycles (temperatures, chemicals and durations), confirm compatibility and any required options with the manufacturer.

6. What certifications does the pump carry and what do they signify?

The pump is certified 3-A-02-11 NO.1759 (a sanitary standard commonly used in the food and dairy industry) and CE-MD/06-42 NO.705201402401-00 (indicating conformity with applicable EU machinery directives).

7. How long does delivery take?

Typical delivery time is normally 10–15 working days after receipt of the down payment.

8. What installation considerations should I be aware of?

Ensure correct alignment and mounting, select a motor/drive compatible with the pump's RPM range, avoid running the pump outside its suction and pressure limits to prevent cavitation, and follow piping practices to minimize strain and air ingress. Refer to the manufacturer's installation manual for specifics.

9. What routine maintenance is recommended?

Regularly inspect seals, O-rings and fittings; check for leaks, vibration and abnormal noise; keep internal surfaces clean; replace wear parts per the manufacturer's schedule. Frequency depends on fluid properties and duty cycle — request the maintenance schedule from the supplier.

10. What types of fluids can this pump handle?

The pump handles a wide range of fluids used in food, pharma and many chemical processes. 316L is compatible with many acids, alkalis and organic solvents, but aggressive chloride environments or highly oxidizing media may require compatibility verification. Always confirm chemical compatibility for your specific fluid.

11. Can the pump handle liquids at the maximum temperature of 80 °C continuously?

Yes, the pump is rated for up to 80 °C; however, seals, gaskets and any connected motor or instrumentation must also be rated for continuous operation at that temperature. Consult the supplier to confirm full-system compatibility for your operating profile.

12. What spare parts should I keep on hand?

Common recommended spares include mechanical seals, O-rings/gaskets, impellers (if applicable), bearings and fasteners. The exact parts depend on the pump model and configuration — request a spare-parts list from your supplier.

13. How durable is the pump and what affects its service life?

Durability is high due to 316L construction and superior surface treatment, but actual service life depends on operating conditions (abrasiveness, temperature, pressure cycles), maintenance practices and chemical compatibility. Proper installation and preventive maintenance will maximize lifespan.

14. What motor and power options are available or required?

The pump requires a motor and drive sized to deliver the desired flow/pressure within the 950–2,900 RPM range. Specific motor power and mounting depend on system head, fluid viscosity and duty cycle. Contact the supplier with your line conditions for recommended motor options.

15. How do I order or request a quote, and can the pump be customized?

Contact the pump supplier or sales representative with your required flow, head/pressure, fluid type, temperature, and any hygiene or certification needs. Customization (different end connections, seal materials, or documentation) may be available — ask the supplier for lead times and any additional costs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading