B21, China Town Mall, Midrand

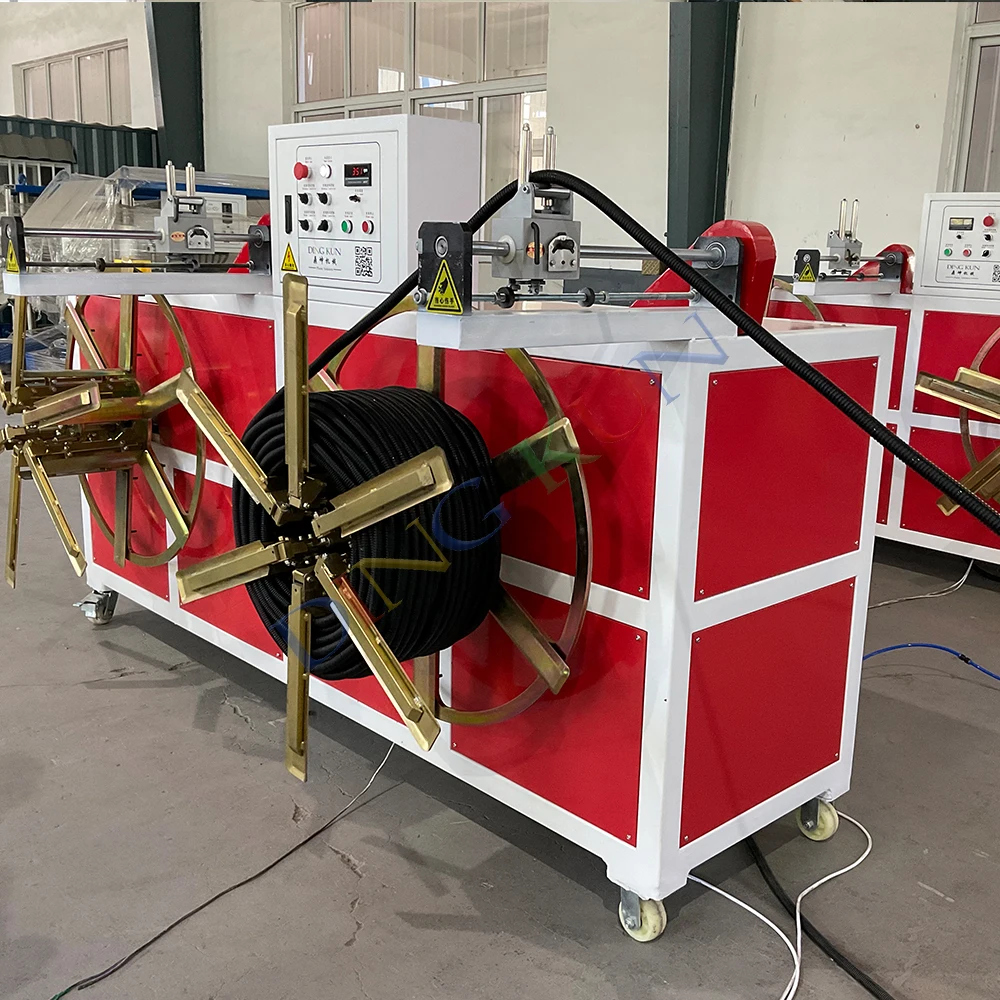

30m/minute High speed Water smoking Shisha Hookah hose making machine / plastic corrugated pipe extrusion line

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 1600964893366

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the 30m/minute High Speed Water Smoking Shisha Hookah Hose Making Machine process?

The machine is designed to process PVC, PP, and PE materials for producing single-wall corrugated pipes.

2. What is the diameter range for pipes produced by this machine?

This machine can produce pipes with diameters ranging from 5mm to 110mm.

3. What is the production speed of the machine?

The machine operates at speeds of 3 to 12 meters per minute, ensuring efficient production.

4. Can the molds be customized for different production needs?

Yes, the molds can be customized with 52, 64, or 72 pairs based on customer requirements.

5. How long does it take to change the size of the machine?

The machine allows for quick size changes without needing to disassemble it, saving over two hours in setup time.

6. What is the capacity of the extruder?

The extruder capacity varies by model: SJ305 can handle 10 kg/h, SJ509 can handle 40 kg/h, and SJ6516 can handle 80 kg/h.

7. What type of control system is used in the machine?

The machine is equipped with a Siemens touch control system, RKC, or Omron table control for ease of operation.

8. What is the power requirement for the machine?

The motor power options available are 18.5 kW, 22 kW, or 30 kW, depending on the extruder model.

9. Does the machine support automatic winding?

Yes, the machine features a double station winding system that automatically winds 50m or 100m rolls.

10. What are the cooling methods used in the high-speed forming machine?

The high-speed forming machine uses water cooling to maintain consistent production quality.

11. Can I engrave a logo on the molds?

Yes, the molds can be customized to include logo engravings.

12. What industries can benefit from this machine?

This machine is ideal for industries such as wiring protection, automotive, air conditioning, and drainage systems.

13. What are the electrical specifications of the machine?

The machine is equipped with high-quality electrical components, including ABB inverters, Siemens motors, and Schneider contactors, complying with CE export standards.

14. Is the machine suitable for high-volume production?

Yes, the advanced technology and efficient production speed make it a cost-effective choice for high-volume production needs.

15. What is the production process for the pipes?

The production process includes raw material mixing, vacuum feeding, material drying, single screw extrusion, forming, double disc winding, and finished product inspection & packing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading