B21, China Town Mall, Midrand

300tph Copper Mineral Processing Plant copper Gold Ore

- Section : Machinery

- Category : Mineral Separators

- SKU : 1601038418880

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

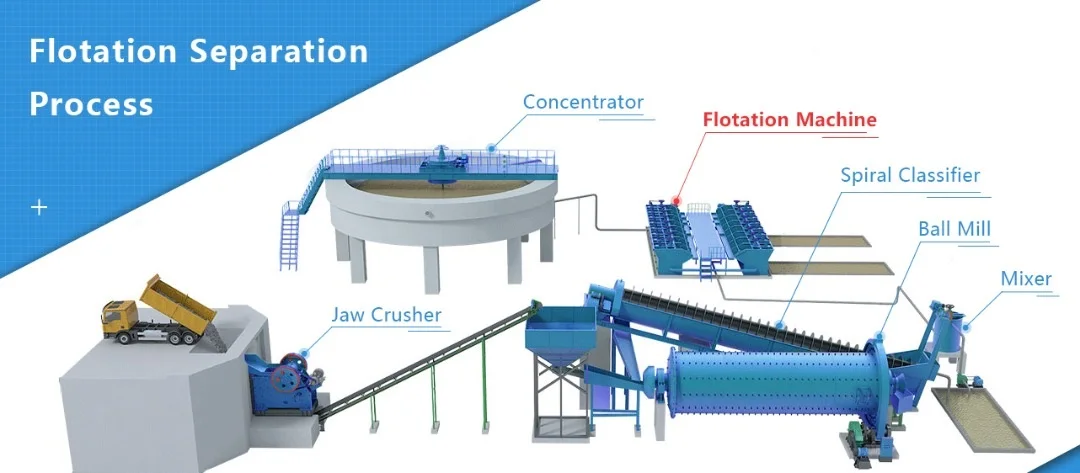

1. What is the main function of the 300tph Copper Mineral Processing Plant?

The main function of the 300tph Copper Mineral Processing Plant is to separate valuable minerals, particularly copper and gold, from non-valuable minerals using the flotation process.

2. How does the flotation process work?

The flotation process works by mixing ore pulp with chemicals to create a slurry, which is then aerated. Valuable minerals adhere to air bubbles and float to the surface, forming a froth that can be collected, while other minerals remain in the slurry.

3. What types of ores can be processed with this flotation machine?

This flotation machine can process a variety of ores, including ferrous metal ores (like iron and manganese), precious metal ores (like gold and silver), non-ferrous metal ores (like copper and lead), sulfide minerals, oxide minerals, and non-metallic minerals.

4. What is the capacity of the flotation machine?

The flotation machine has varying capacities depending on the model, ranging from 36 tons per hour to 129 tons per hour.

5. What is the recovery rate for copper using this processing plant?

The recovery rate for copper can be as high as 95.24%, depending on the specific ore characteristics and processing conditions.

6. What are the benefits of using this flotation machine?

The benefits include high recovery rates, cost-effectiveness, the ability to process various types of minerals, and minimized environmental impact during the flotation process.

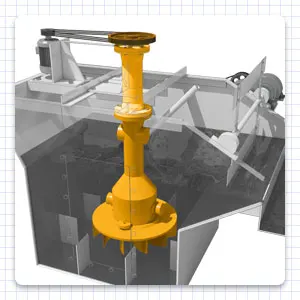

7. What is the role of the aeration device in the flotation machine?

The aeration device is responsible for introducing air into the slurry, creating bubbles that facilitate the attachment of valuable minerals and their subsequent flotation to the surface.

8. What are the specifications of the flotation machine?

Specifications vary by model, including cylinder diameter, length, field strength, rotating speed, dry ore processing capacity, pulp concentration, motor power, and dimensions.

9. Is the flotation machine self-priming?

Yes, the flotation machine is designed to be self-priming, which enhances its operational efficiency.

10. Can this flotation machine be customized for different projects?

Yes, the flotation machine can be customized based on specific project requirements and ore characteristics.

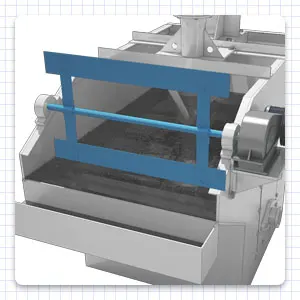

11. What is the maintenance requirement for the flotation machine?

Regular maintenance is essential to ensure optimal performance, including checking the impeller, aeration device, and slurry levels, as well as replacing worn parts as necessary.

12. What materials are used in the construction of the flotation machine?

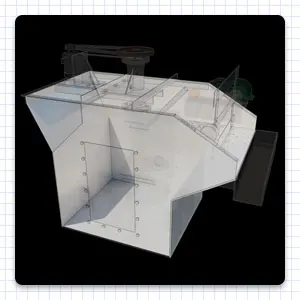

The flotation machine is primarily constructed from high-quality steel plates to ensure durability and performance.

13. How does the flotation machine minimize environmental impact?

The flotation machine is designed to maximize recovery and minimize waste, which helps to reduce the overall environmental footprint of the mineral processing operation.

14. What types of chemicals are used in the flotation process?

Chemicals used in the flotation process typically include collectors, frothers, and modifiers, which help enhance the separation of valuable minerals.

15. What safety features does the flotation machine have?

Safety features include emergency stop buttons, protective covers, and safety interlocks to prevent accidental operation during maintenance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading