B21, China Town Mall, Midrand

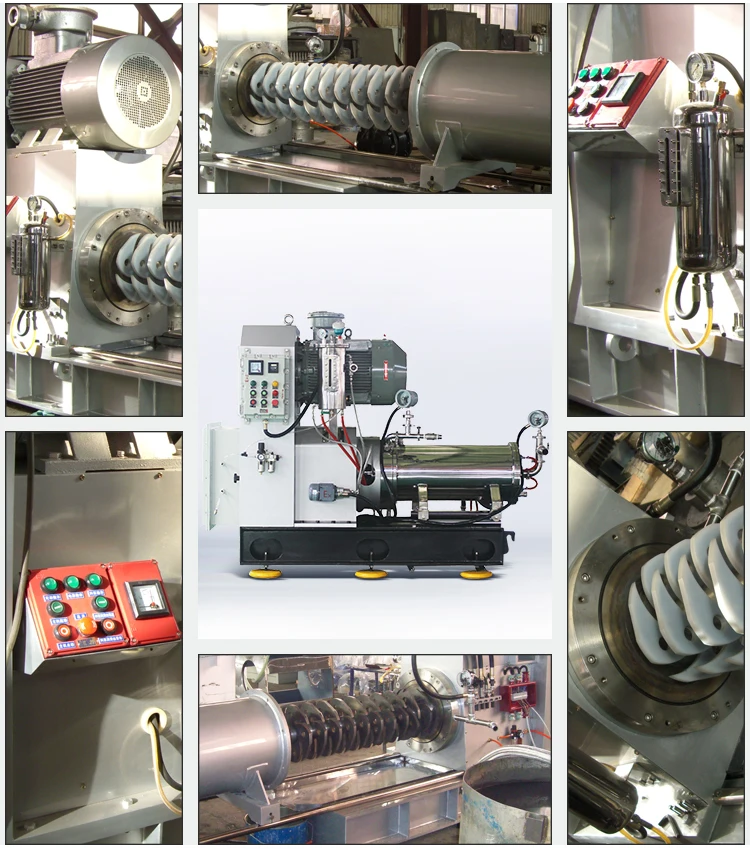

2L Laboratory Bead Mill for Biotechnology Grinding Equipment BSM-2

- Section : Machinery

- Category : Chemical Machinery

- SKU : 1601132565573

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 25 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

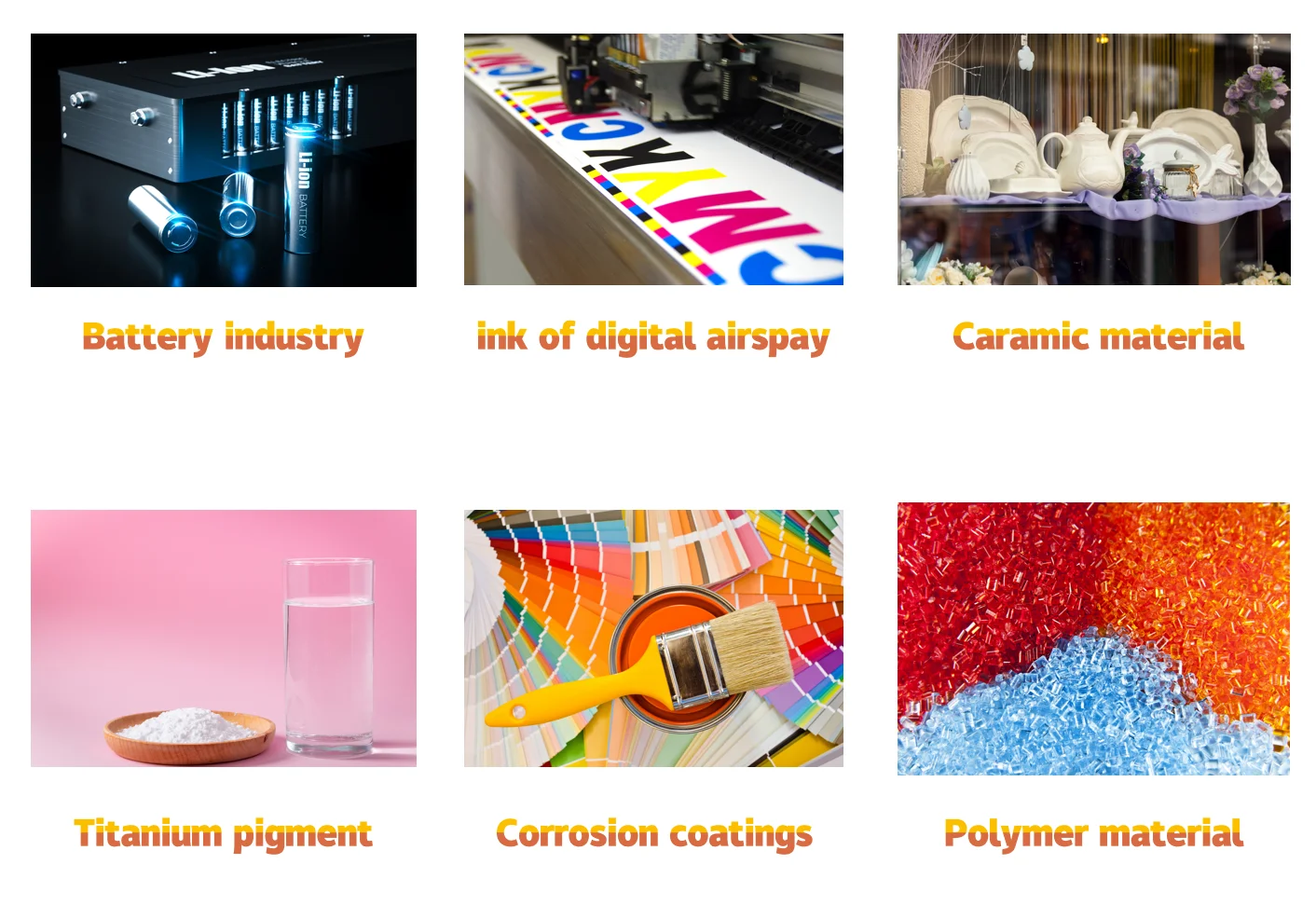

1. What materials can the 2L Laboratory Bead Mill grind?

The 2L Laboratory Bead Mill is designed for a wide range of applications including chemicals, plastics, food processing, and biotechnology. It is particularly effective for grinding battery materials and other fine materials.

2. What is the effective volume of the bead mill?

The effective volume of the 2L Laboratory Bead Mill is 2 liters.

3. Is the bead mill energy efficient?

Yes, the bead mill is designed to save energy while providing superior grinding results, ensuring long-term cost-effectiveness.

4. What is the range of particle sizes that can be achieved?

The bead mill can achieve extremely fine particle sizes using zirconia bead grinding media with diameters ranging from 0.3 to 1.0 mm.

5. Does the bead mill have automatic operation?

Yes, the 2L Laboratory Bead Mill features automatic operation, ensuring consistent performance with minimal operator intervention.

6. What type of motor does the bead mill use?

The bead mill is equipped with an explosion-proof motor that meets safety standards for hazardous environments, with customized motor options available.

7. What materials is the bead mill constructed from?

The bead mill is constructed from SUS304/SUS304L stainless steel, providing resistance to corrosion and long-lasting durability.

8. How does the cooling system work?

The bead mill features a circulating water cooling system that prevents overheating during operation, ensuring stable performance.

9. What voltage options are available for the bead mill?

The bead mill is customizable with different voltage options, including 220V, 380V, 440V, and 460V to meet various requirements.

10. What is the spindle speed range of the bead mill?

The bead mill offers an adjustable spindle speed range of 1 to 1120 r.p.m. to accommodate various grinding tasks.

11. What are the dimensions of the bead mill?

The dimensions of the bead mill are 1150 mm in length, 1110 mm in width, and 1250 mm in height.

12. Is there post-sales support available?

Yes, post-sales support is provided online after the warranty period to ensure continued satisfaction and assistance.

13. What certifications does the bead mill have?

The bead mill includes a machinery test report and video outgoing inspection for quality assurance.

14. Can the grinding chamber materials be customized?

Yes, the grinding chamber can be customized with options including polyurethane, silicon carbide, and cemented carbide.

15. What safety features does the bead mill have?

The bead mill includes multiple safety controls such as feeding pressure, output temperature, and mechanical seal lubricant oil level monitoring.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading