B21, China Town Mall, Midrand

2023 Metal Forging Bending Machine

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 60586338986

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of materials can the 2023 Metal Forging Bending Machine bend?

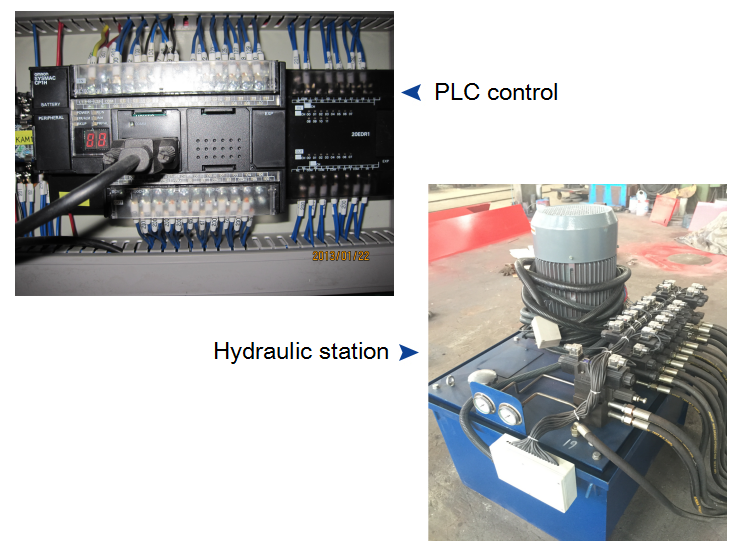

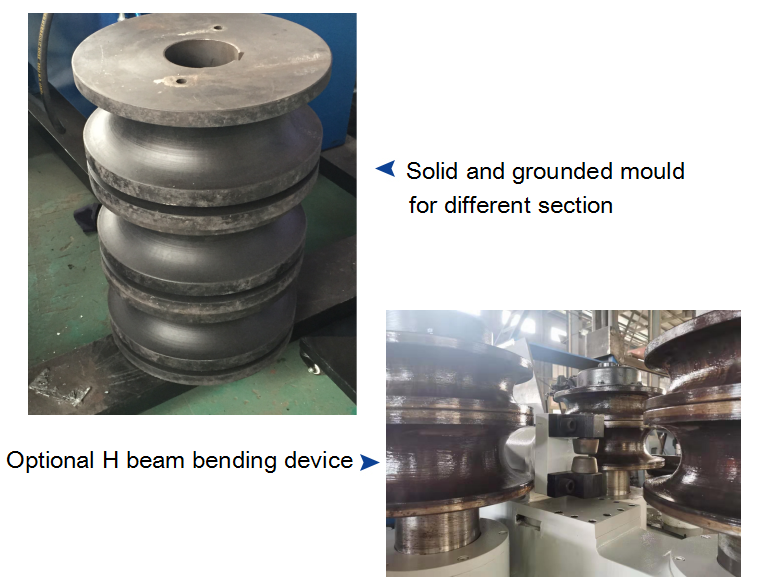

The W24S Full Hydraulics Profile Bending Machine can bend a wide variety of profiles including angle irons, channels, I-beams, flat bars, square tubes, and pipes.

2. How does the hydraulic system work in this bending machine?

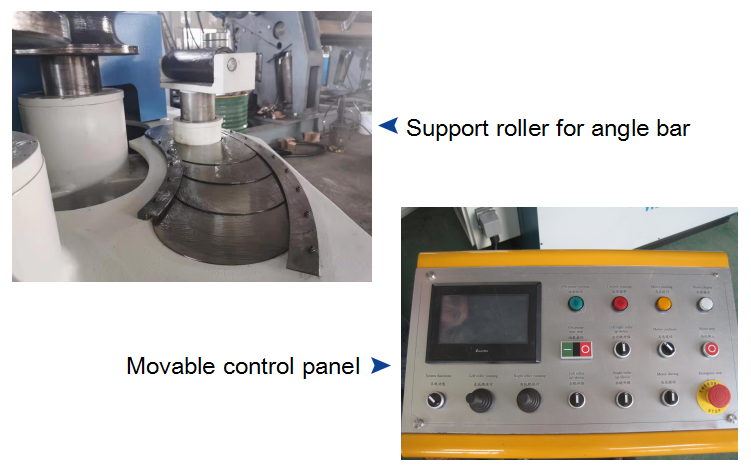

The machine utilizes a hydraulic motor drive system with a planetary/gear system to ensure smooth operation and precise bending control.

3. What is the maximum bending capacity of the machine?

The specific maximum bending capacity can vary based on the profile and material used; please refer to the technical specifications for detailed capacity information.

4. Is the bending machine easy to operate?

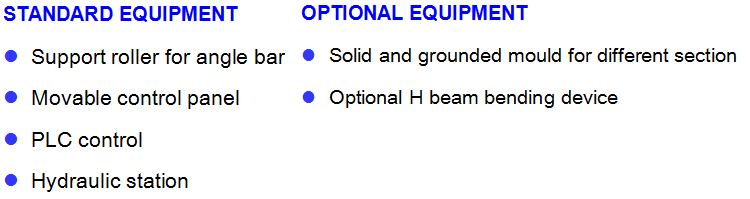

Yes, it features a portable control panel that is user-friendly, allowing for easy operation with minimal training required.

5. Can the bending machine operate in both horizontal and vertical positions?

Yes, the machine offers operational flexibility with both horizontal and vertical operation options.

6. What safety features does the machine have?

The machine is equipped with integrated hydraulic and electrical overload protection to ensure safe operation.

7. What is the construction material of the machine's body?

The machine's body is made from stress-relieved steel, ensuring stability and longevity during operation.

8. What brands are used for the components in this machine?

The machine includes components from reputable brands, such as Omron for the PLC, Yuken for the valves, and double-row self-aligning roller bearings by WFD.

9. How are the bottom rolls adjusted?

The bottom rolls can be adjusted hydraulically with a digital readout for precise bending control.

10. What is the hardness of the mould material used in this machine?

The mould material has a hardness of HRC50-55, sourced from Nangang/Huawei.

11. What type of oil tank is used in the hydraulic system?

The oil tank is made from Steel 45 with quenching, rated between HB217-255.

12. What is the function of side support rollers?

The side support rollers are specifically designed to assist in bending angle iron and facilitate leg-in-leg-out bending.

13. Is the machine suitable for high-efficiency production needs?

Yes, the W24S Full Hydraulics Profile Bending Machine is designed for high efficiency, making it suitable for various industrial applications.

14. What kind of maintenance does the machine require?

Regular maintenance includes checking the hydraulic fluid levels, inspecting seals, and ensuring that all components are functioning properly for optimal performance.

15. Where can I find support or service for this machine?

Support and service can typically be obtained through the manufacturer's website or authorized distributors. Please check the warranty information for further details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading