B21, China Town Mall, Midrand

1-100G Grain Snus Chilli Pepper Spice Bag Filling Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600892314016

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 02 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products can this machine pack?

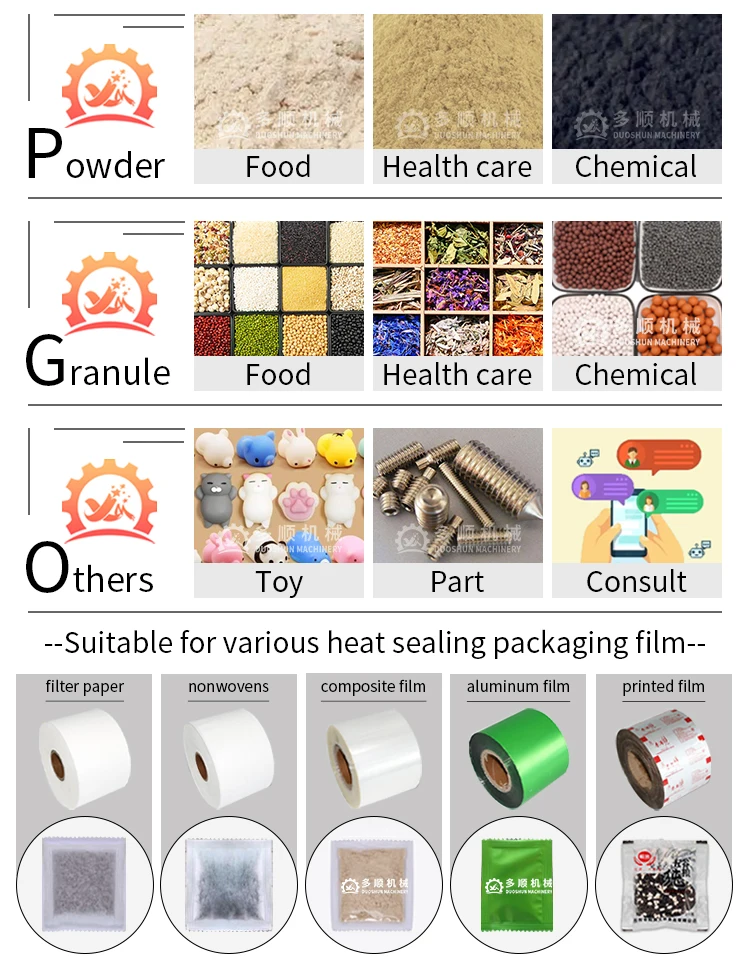

The machine is designed for particle and powder products such as grain snus, chilli pepper flakes, spices, powders and similar small-particle materials.

2. What is the production speed (bags per minute)?

Production capacity is 5–20 bags per minute, adjustable via the subpackage controller (fast, medium, slow).

3. What packaging weights and sizes does it support?

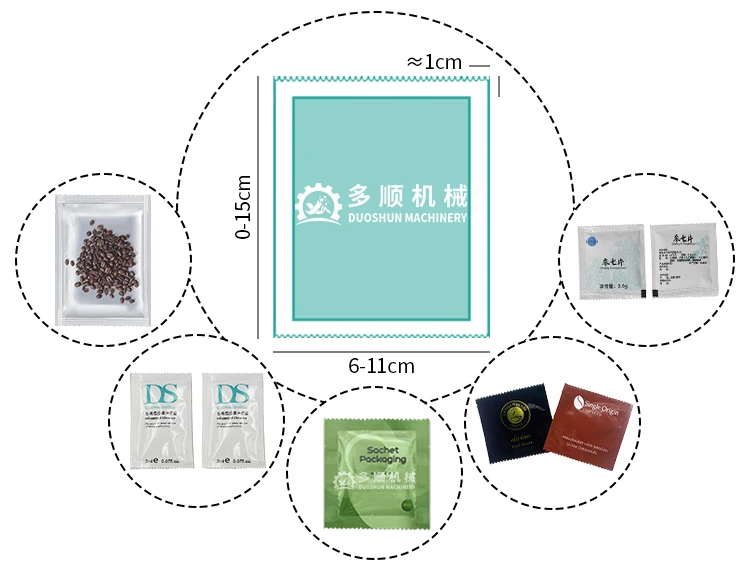

It supports packaging weights of 1–20g, 1–50g and 1–100g. The pouch length is up to 15 cm (0–15 cm or 1–15 cm depending on spec) and packaging width for the DZD-220SBF model is 6–11 cm (film width 12–22 cm).

4. How accurate is the dosing/weighting?

Packaging accuracy is typically between 0.1–0.3 g when using the standard electronic scale.

5. What are the electrical requirements and power consumption?

Standard power is 220V, 50Hz with a power consumption of 500W.

6. What are the machine dimensions and weight?

For the DZD-220SBF model the dimensions are 550 × 620 × 1800 mm and the machine weight is approximately 80 kg. Other models (DZD-220 / DZD-220B) have smaller footprints and weigh about 50 kg.

7. What materials and components contact the product?

Product-contact parts are made of stainless steel for hygiene and easy cleaning; other structural components are industrial-grade materials suited for food and spice applications.

8. What optional features are available?

Optional features include ribbon coding (automatic date/batch printing), film tracking cursor (for registered printed film), and alternate feeders such as screw feeding or counting feeding for custom applications.

9. Can the former and feeder be customized?

Yes. The former size (which determines final pouch width) can be customized and different feeder types (screw, counting, etc.) are available to match your product characteristics.

10. How does the machine seal and cut pouches?

The machine performs automatic vertical heat-sealing for the pouch side and horizontal heat-sealing for top/bottom seals. Temperatures are adjustable for different films. After sealing the horizontal seals, the machine cuts pouches one by one.

11. What safety and control features does it include?

The machine has an emergency stop switch, sealing and subpackage controllers, a barometer, and a sealing locker. Controls allow temperature adjustment, pouch length setting, speed selection and emergency shutdown.

12. How easy is it to change film or printed film registration?

Film changes are straightforward. If you use printed film, the optional cursor (photo eye) ensures accurate registration so each printed image aligns with pouch seals. Blank film does not require the cursor.

13. What cleaning and maintenance are required?

Regular cleaning of product-contact surfaces (stainless steel) is recommended, along with routine inspection of seals, heater blocks, belts and electrical connections. Power should be disconnected before cleaning or maintenance. Replace worn sealing elements and check the scale calibration periodically.

14. Is installation, commissioning or operator training provided?

Installation, commissioning and operator training are commonly offered by suppliers—please contact the vendor to arrange on-site support or remote guidance as required.

15. What warranty, spare parts and after-sales support are available?

Warranty terms, spare parts availability and after-sales support vary by supplier. Most suppliers provide spare parts (heaters, sealing elements, sensors) and technical support; contact the vendor for specific warranty and spare-parts details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading