B21, China Town Mall, Midrand

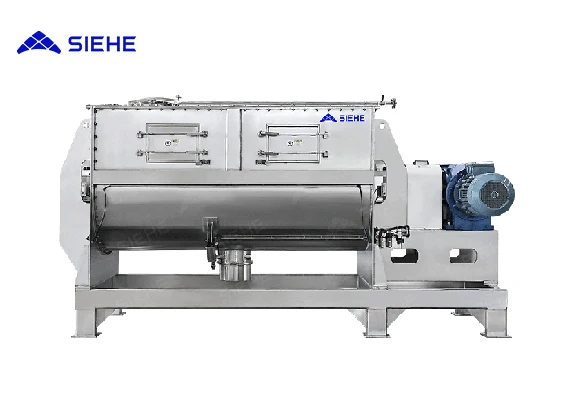

100-5000 Liter Food Spice Ingredients Powder Granular Blender Powder Mixing Machine

- Section : Machinery

- Category : Mixing Equipment

- SKU : 1601221133886

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries can the Ribbon Blender Mixing Machine be used in?

The Ribbon Blender Mixing Machine is suitable for various industries including food processing, chemical manufacturing, and the plastic industry. It can blend spices, food ingredients, powdered chemicals, and granules.

2. What is the capacity range of this mixing machine?

The machine is available in capacities ranging from 100 liters to 30,000 liters, providing flexibility for different production scales.

3. What materials is the Ribbon Blender made of?

The Ribbon Blender is constructed from high-quality stainless steel materials such as SUS304, SUS304L, SUS316, and SUS316L, ensuring durability, corrosion resistance, and hygiene for food-grade processing.

4. Is the Ribbon Blender safe for use in hazardous environments?

Yes, the machine is ATEX certified, making it explosion-proof and safe for operation in hazardous environments.

5. How efficient is the blending process?

The ribbon mixing design of the machine allows for highly efficient and even mixing of powders and granules, ensuring consistent results every time.

6. What is the power requirement for the mixer?

The Ribbon Blender is equipped with a powerful 15 kW motor, and it operates on a voltage range of 220-600V.

7. Can the mixing machine handle both powders and liquids?

Yes, the Ribbon Blender can mix powders, granular materials, and liquids with fluidity, such as putty and reactive dyes.

8. What are the options for controlling the machine?

The machine comes with button control or PLC control options, allowing for easy operation and customization based on user needs.

9. How does the machine ensure uniform mixing?

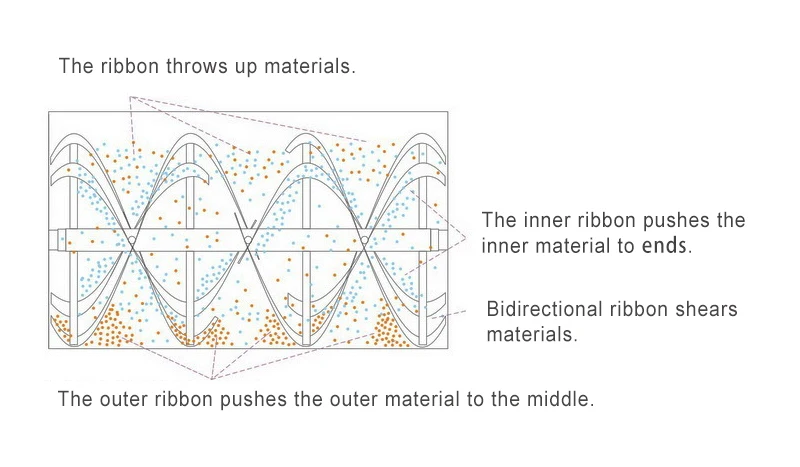

The design features an inside and outside double ribbon agitator that drives materials from both ends to the middle, resulting in higher mixing efficiency and uniformity.

10. What is the weight of the Ribbon Blender?

The machine weighs approximately 2300 kg, which contributes to its stability during operation.

11. Are there customizable features for the Ribbon Blender?

Yes, the mixer can be customized with options such as spray systems, vacuum systems, heating systems, and different sealing methods, among others.

12. What is the spindle speed range for this mixer?

The spindle speed range of the Ribbon Blender is 0 to 47 r.p.m, which allows for various mixing operations.

13. What type of maintenance is required for the machine?

The machine is designed for ease of maintenance, primarily due to its stainless steel construction, which facilitates cleaning and upkeep.

14. Can this blender handle high-temperature materials?

Yes, the machine can be designed to handle materials with temperatures around 180º-300ºC, depending on the configuration.

15. What types of valves are available for this machine?

The Ribbon Blender can be equipped with various types of valves, including plum blossom valves, butterfly valves, flap valves, and ball valves, depending on the application.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading