B21, China Town Mall, Midrand

1000 Ton Hot Metal Forging Machinery Press

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600303628438

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

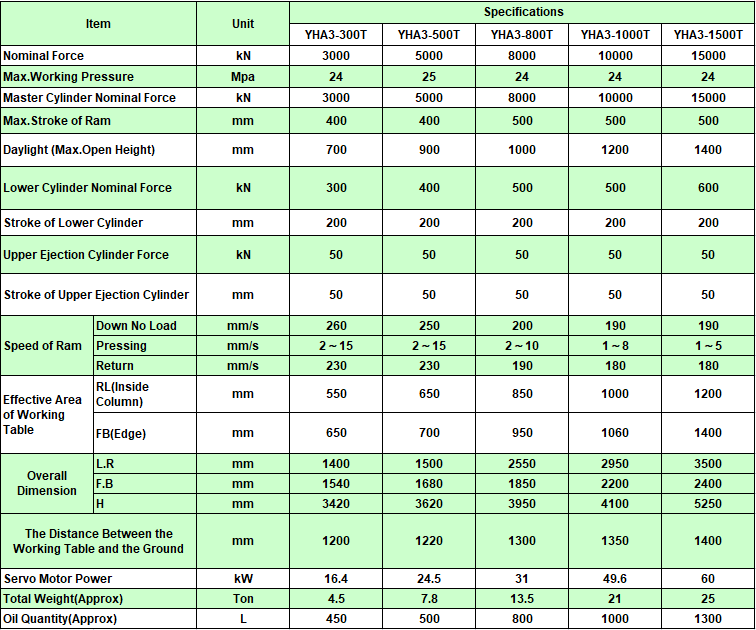

1. What is the capacity of the 1000 Ton Hot Metal Forging Machinery Press?

The 1000 Ton Hot Metal Forging Machinery Press has a capacity of 1000 tons, making it suitable for heavy-duty metal forming operations.

2. What industries can benefit from using this press?

The 1000 Ton Hot Metal Forging Machinery Press is ideal for industries such as automotive, manufacturing, aerospace, and heavy machinery.

3. How does the servo motor drive system improve efficiency?

The servo motor drive system reduces power consumption by up to 65% and provides high control precision with speed errors as low as 0.0001/r.

4. What safety features are included with the press?

Safety features include password protection, operation instructions, and real-time monitoring to ensure safe and effective usage.

5. Is the press suitable for high-speed operations?

Yes, the press has a speed overload function that allows for achieving 2-3 times the rated speed for versatile operations.

6. What materials are the main components sourced from?

The main components are sourced from Germany, Italy, and Japan, ensuring top-tier quality and reliability.

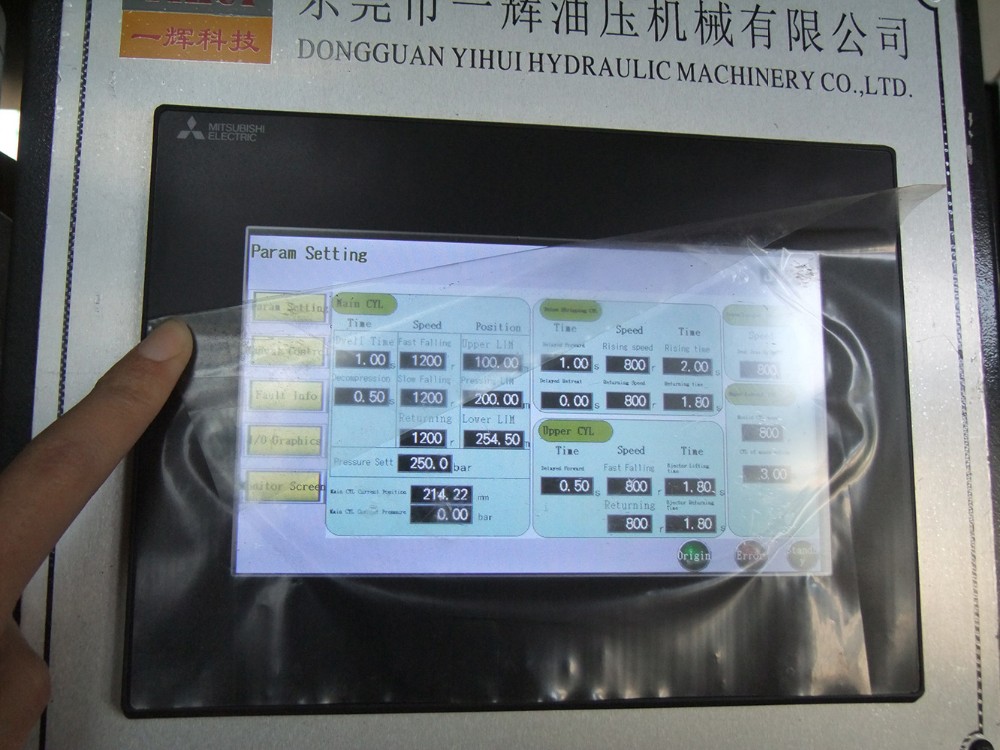

7. Can the touch screen control system be customized?

Yes, the advanced touch screen control allows for customizable settings for speed, pressure, and strike force according to specific needs.

8. What types of metal forming processes can this machine handle?

This press is suitable for various metal forming processes including fine blanking, cold extrusion, and stamping of metallic and non-metallic parts.

9. How does the leak-proof design benefit the machine?

The leak-proof design with clip-on oil pipes prevents oil leakage, ensuring reliability and reducing maintenance needs.

10. What is the construction quality of the press?

The press features a sturdy construction using a bending structure for added strength, making it more durable than typical welding structures.

11. Is this press easy to maintain?

Yes, the press is designed for easy maintenance with an integrated oil manifold block that facilitates troubleshooting and upkeep.

12. What are some examples of parts that can be produced with this press?

Examples include auto spare parts, LED radiators, cellphone casings, and various hardware tools.

13. Does the press offer real-time monitoring?

Yes, the touch screen system provides real-time monitoring of working status, production progress, and error reports.

14. What is the advantage of using this press for production?

The 1000 Ton Hot Metal Forging Machinery Press delivers high precision, energy efficiency, and durability, ensuring top-notch results while reducing operational costs.

15. Are there related products available?

Yes, related products include the 200 ton 4 column stamping automatic servo hydraulic press machine and the 400 ton gib guided sliding servo hydraulic press machine for metal forming.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading