B21, China Town Mall, Midrand

ZTRFM Purlin Roll Forming Machine Steel Frame Machine C Z Purlin Roll Forming Machine Full Automatic

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600979011645

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 12 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

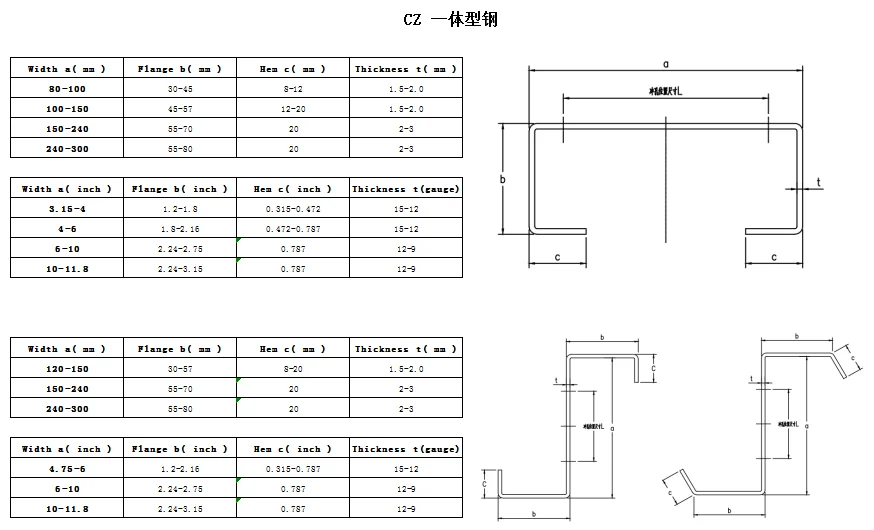

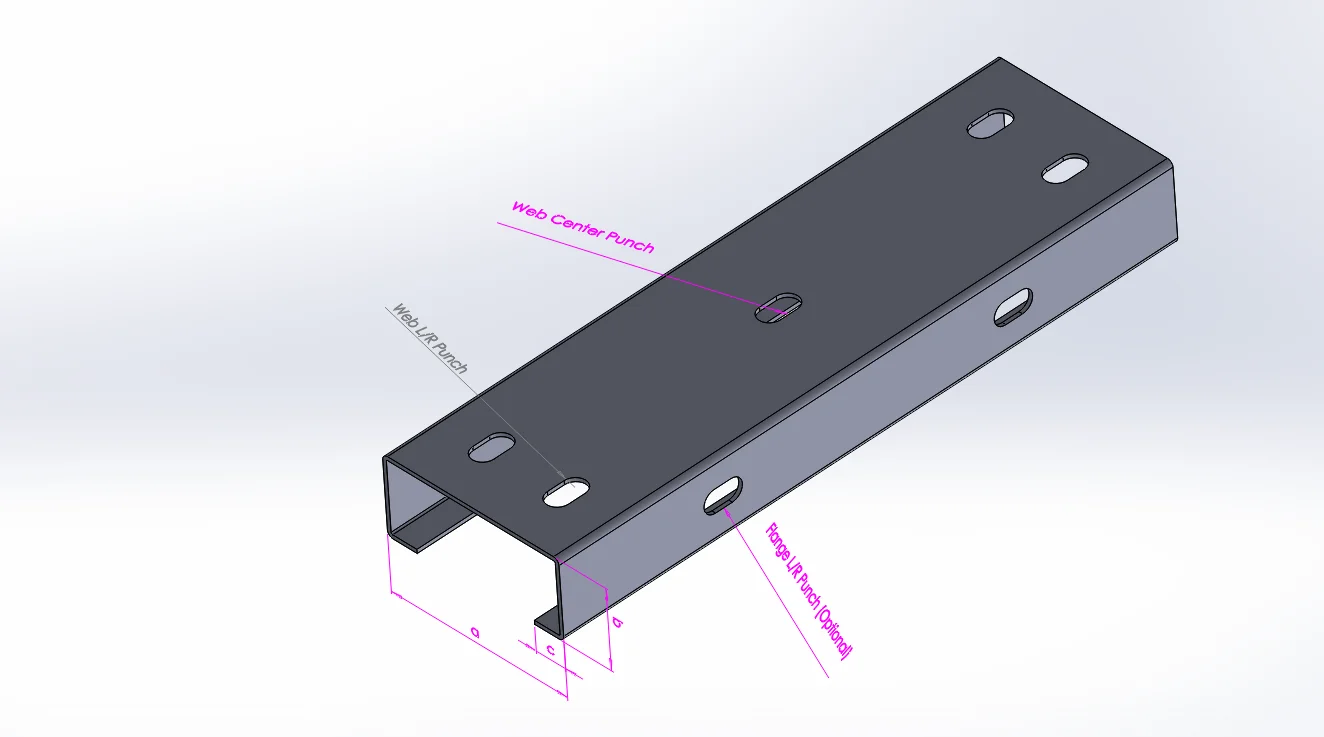

1. What types of purlins can the ZTRFM Purlin Roll Forming Machine produce?

The ZTRFM Purlin Roll Forming Machine can produce both C and Z purlins, with sizes ranging from 80 to 300 mm in width and thickness from 1 to 3 mm.

2. What is the maximum forming speed of the machine?

The maximum forming speed of the ZTRFM Purlin Roll Forming Machine is 30 meters per minute.

3. What type of power system does this machine use?

This machine uses a fully hydraulic system instead of a normal power system, which helps to save energy and reduce operating costs.

4. Can the machine be customized for different specifications?

Yes, the ZTRFM Purlin Roll Forming Machine can be customized for special sizes beyond the standard specifications.

5. What materials can be processed by this machine?

The ZTRFM Purlin Roll Forming Machine can process PPGI and PPGL materials, with a thickness range of 1 to 3 mm.

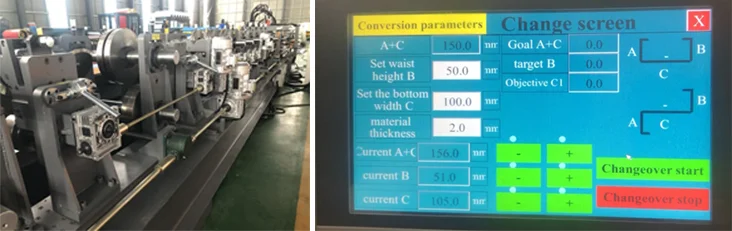

6. How does the machine control size adjustments?

Size adjustments are controlled by a PLC system, allowing for automatic changes in specifications and easy switching between C and Z purlins.

7. What safety features does the machine have?

The machine is equipped with two emergency stop buttons and a robust frame made of welded U beam steel for safety during operation.

8. What is the voltage requirement for the machine?

The ZTRFM Purlin Roll Forming Machine operates on a voltage of 380V, 50Hz, and 3-phase power, but it can be adjusted as requested.

9. What is the material used for the rollers and shafts?

The rollers are made of high-grade 45# forged steel, while the shafts are made of 40 Cr steel, both processed to ensure durability and longevity.

10. Is the machine easy to operate?

Yes, the machine features a user-friendly PLC control system with an interface in English and Chinese, making it easy to set orders and adjust parameters.

11. What is the cutting method used in this machine?

The ZTRFM Purlin Roll Forming Machine uses a hydraulic post-cutting method, which allows for precise cuts and easy size adjustments.

12. Can the machine handle heavy coils?

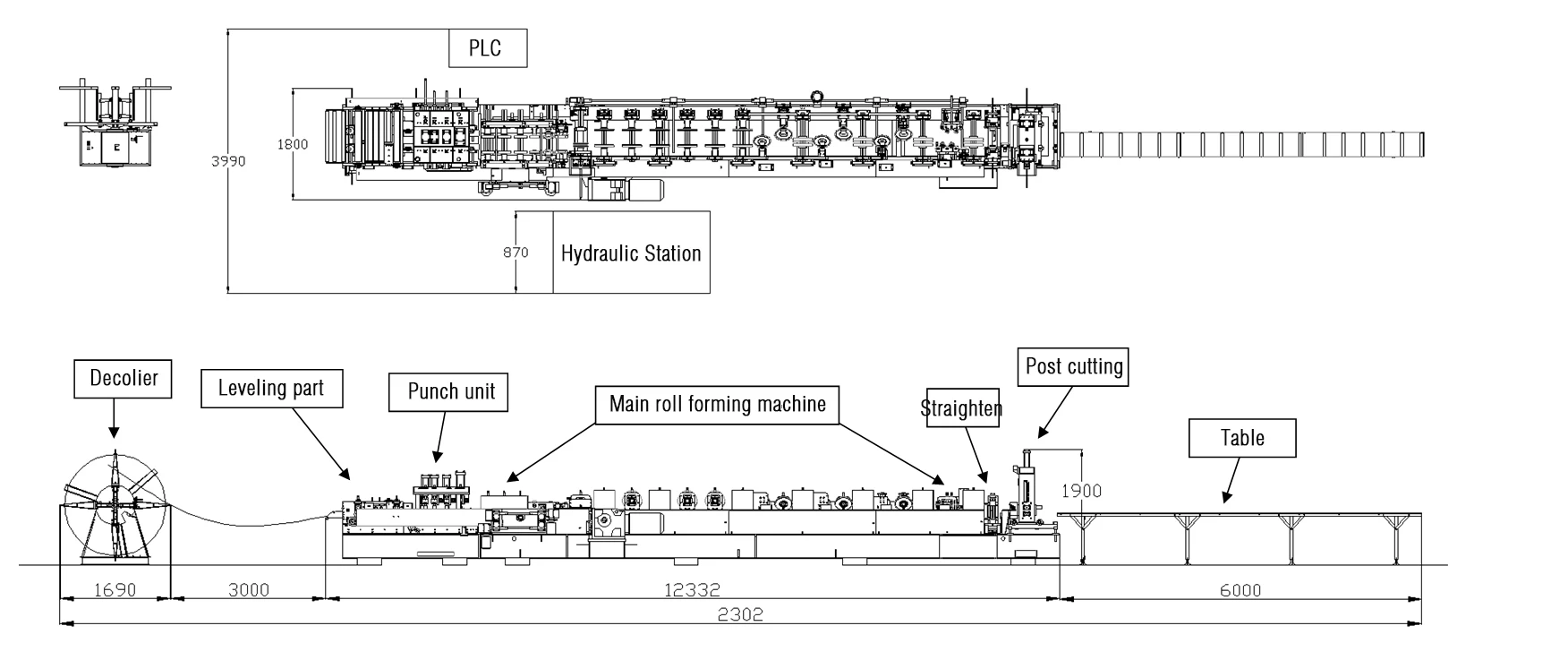

Yes, the machine includes a 5-ton manual decoiler that can accommodate coils with an inner diameter of 450-550 mm.

13. What brands of components are used in the PLC system?

The PLC system uses Delta (Taiwan) for the PLC, Omron for the encoder, and Schneider for other electrical components.

14. Does the machine include a leveling device?

Yes, the machine is equipped with an electric feeding and leveling device that automatically adjusts the feeding width for accurate roll forming.

15. What is the tolerance for length measurements?

The machine has a tolerance of ±1.0 mm for lengths up to 3000 mm, ensuring high accuracy in production.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading