B21, China Town Mall, Midrand

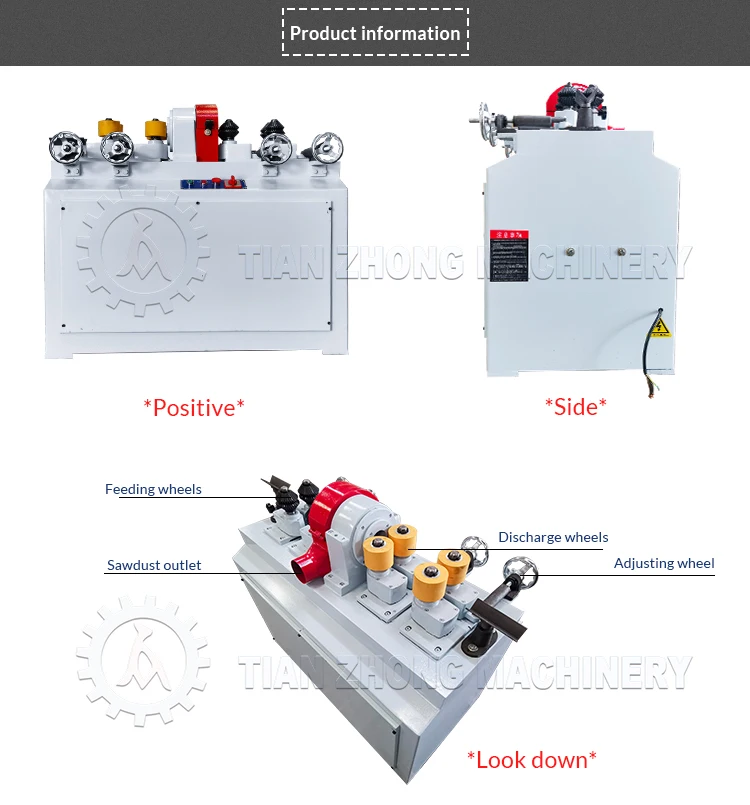

Wood Round Rob Making Machine

- Section : Machinery

- Category : Woodworking Machinery

- SKU : 1600795730187

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the Wood Round Rob Making Machine?

The Wood Round Rob Making Machine, also known as the CNC Tenoner, is designed for creating round rods in woodworking operations, making it ideal for manufacturers looking to enhance their production capabilities.

2. What is the power specification of this machine?

The machine operates with a power of 3 kW, providing the necessary energy for effective cutting and shaping.

3. What are the available voltage options for this machine?

The Wood Round Rob Making Machine is available in both 220V and 380V configurations to accommodate different electrical requirements.

4. What is the adjustable feed speed range of the machine?

The machine features an adjustable feed speed ranging from 3 to 5 m/min, allowing flexibility based on specific project requirements.

5. What is the spindle velocity of the Wood Round Rob Making Machine?

The machine operates at a spindle velocity of 4000 r/min, providing fast and precise cuts for wood processing.

6. What cutting diameters can the machine handle?

The machine is capable of handling cutting diameters from 15 to 50 mm, accommodating various project specifications.

7. Is the machine easy to operate for beginners?

Yes, the Wood Round Rob Making Machine is designed for user-friendly operation, making it accessible for operators of all skill levels.

8. What core components ensure the machine's performance?

The machine is equipped with a powerful engine, durable bearings, and a robust motor, ensuring reliable performance and longevity.

9. What quality assurance measures are included with the machine?

The machine comes with a machinery test report and a video outgoing inspection to ensure it meets stringent quality standards.

10. What are the overall dimensions of the machine models?

The overall dimensions vary by model: MC-9050 (860*650*980 mm), MC-9050A (970*650*980 mm), MC-9050B (1100*650*980 mm), and MC-9050C (1470*590*1000 mm).

11. What is the weight of the different models of the machine?

The machine weights vary by model: MC-9050 (250 kg), MC-9050A (310 kg), MC-9050B (350 kg), and MC-9050C (520 kg).

12. Can the feed speed be adjusted during operation?

Yes, the feed speed can be adjusted during operation to cater to different project requirements.

13. Is there any maintenance required for the machine?

Regular maintenance is recommended to ensure optimal performance and longevity, including checking the motor, bearings, and general cleanliness of the machine.

14. Where can I find replacement parts for the Wood Round Rob Making Machine?

Replacement parts can typically be found through the manufacturer’s website or authorized distributors. Always check with the supplier for compatibility.

15. What type of wood is compatible with this machine?

The machine is designed to work with various types of hardwood and softwood, making it versatile for different woodworking projects.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals