B21, China Town Mall, Midrand

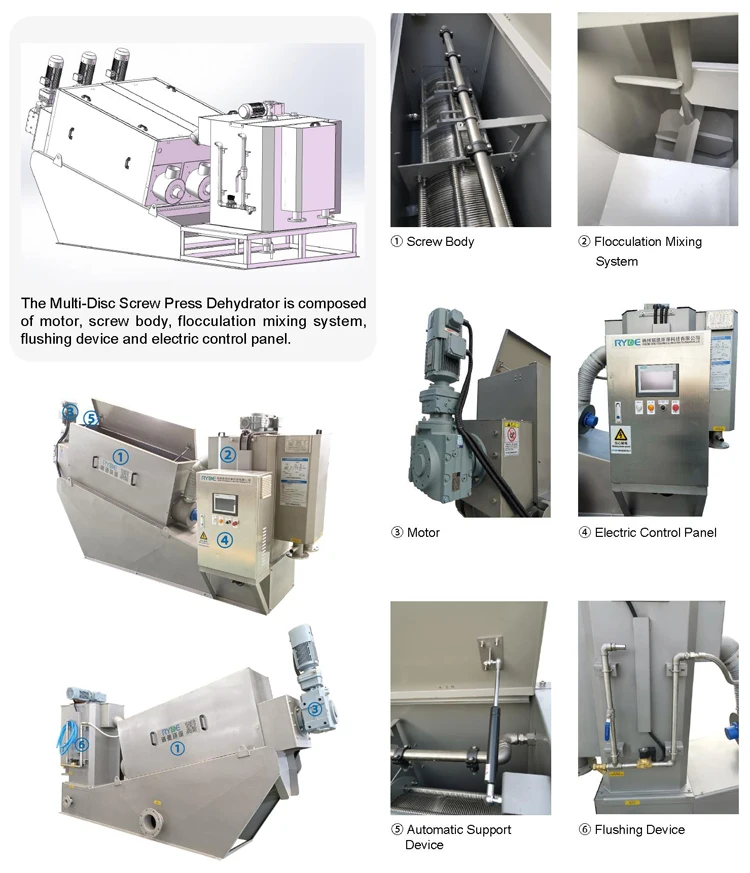

Waste water recycling system vertical screw press sludge treatment volute dewatering screw press machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601102225126

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 13 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the waste water recycling system vertical screw press?

The main function of the waste water recycling system vertical screw press is to dehydrate sludge through solid-liquid separation using screw extrusion principles.

2. What is the capacity of the RDL131 model?

The RDL131 model has a dry sludge treating capacity of 6-12 kg/h.

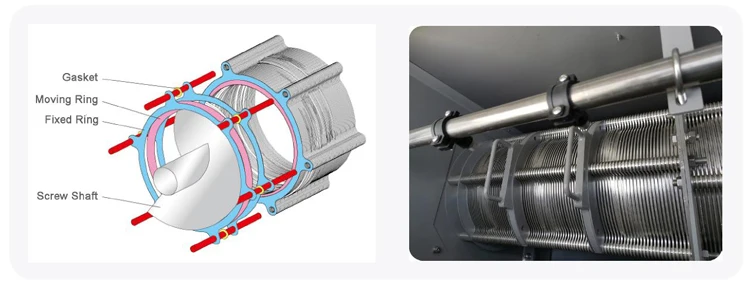

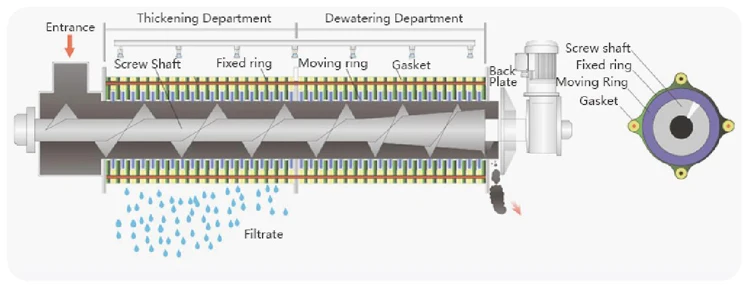

3. What is the moisture content of the output sludge?

The output sludge moisture content is typically between 75-85%.

4. What materials are used in the construction of the screw body?

The screw body is made of SS304, SS316, or SS2205 materials, which provide durability and resistance to corrosion.

5. Does the machine require regular cleaning?

No, this type of dehydrator does not require cleaning as the moving ring in the filtering device is always in motion, preventing clogging.

6. What is the energy consumption of the whole machine?

The power consumption of the machine is 0.36 kW, and it has a water consumption of 28 L/h.

7. What is the required water supply pressure for operation?

The required water supply pressure for operation is ≥0.2 MPa.

8. What type of flocculant is used in the process?

Polymer flocculation is used as a conditioning agent before dehydration, specifically with 2-8g-PAM/kg-DS when the concentration of PAM is 0.1-0.2%.

9. What are the dimensions of the machine?

The dimensions of the machine are 2000 mm in length, 790 mm in width, and 1040 mm in height.

10. Can the electronic control system be customized?

Yes, the electronic control system can be customized according to customer requirements and can include PLC and communication modules.

11. What types of connections are available for the machine?

The machine includes various pipe ports for sludge inlet, filtrate outlet, return flow, sewage outlet, flushing water inlet, and polymer inlet, with specified flange and thread connections.

12. What is the net weight of the machine?

The net weight of the machine is 250 kg, while the operating weight is 390 kg.

13. What is the principle behind the operation of the screw press?

The operation principle is based on screw extrusion, where the rotating screw exerts pressure to dehydrate sludge while filtering out liquid.

14. Is installation assistance provided for the machine?

While the product does not explicitly mention installation assistance, it is advisable to contact the engineers for detailed information and support.

15. Who should I contact for detailed information and engineering drawings?

For detailed information and engineering drawings, you should contact our engineering team directly.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading