B21, China Town Mall, Midrand

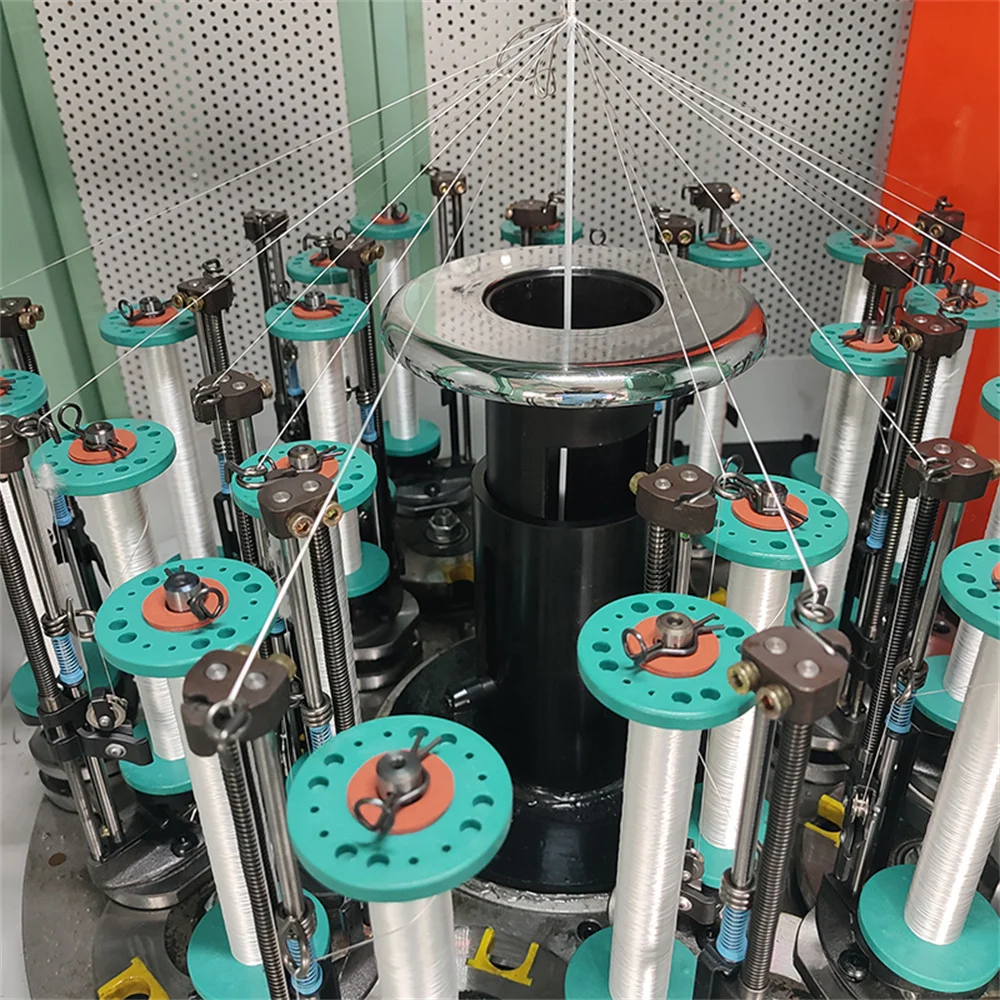

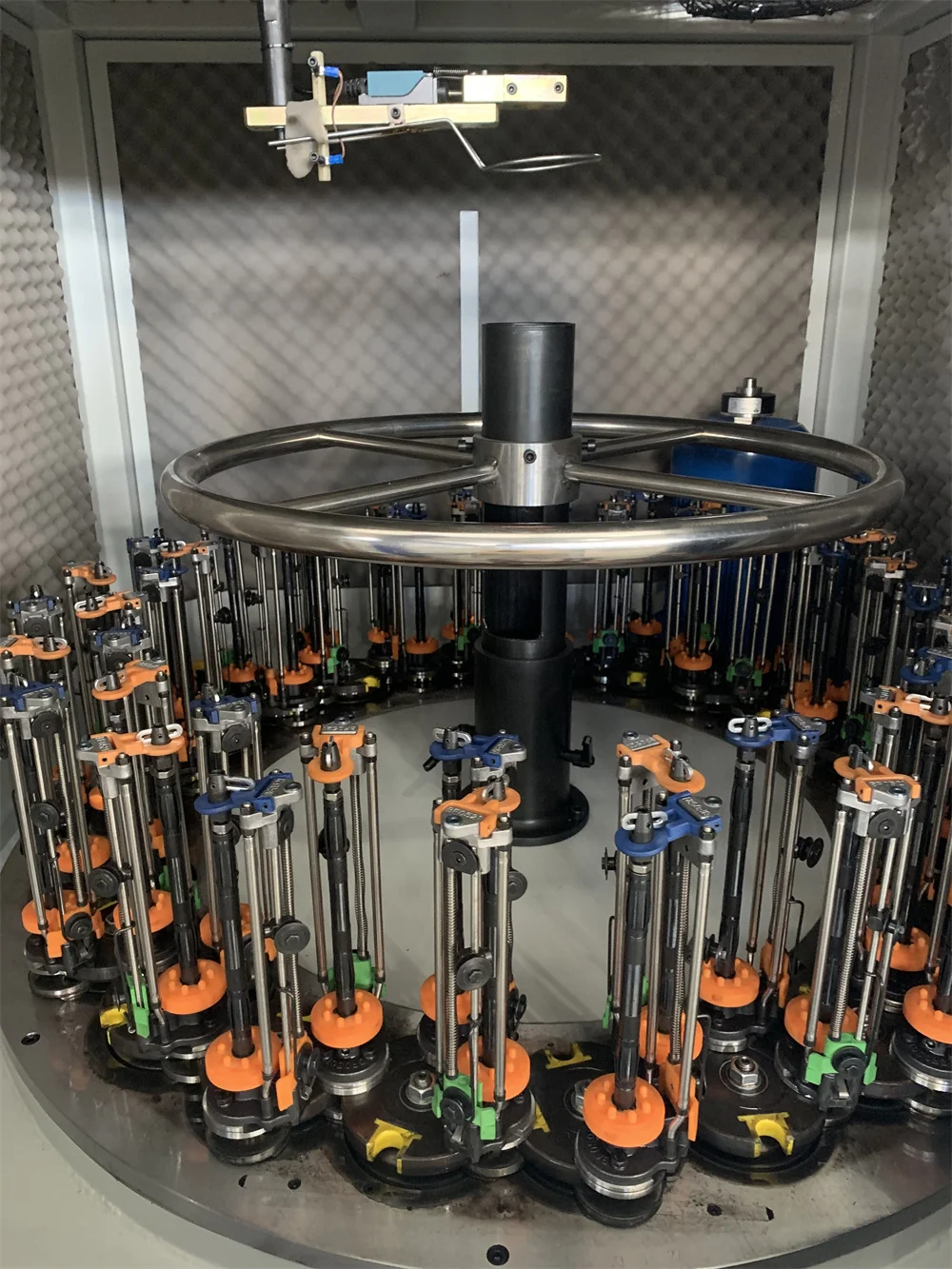

vertical high speed braiding machine wiring harness braiding machine stainless steel hose braiding machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600852573631

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of materials can be braided using the GLT vertical high-speed braiding machine?

The machine can braid various materials including stainless steel wire, nylon wire, aluminum wire, carbon steel, polyester yarn, cotton yarn, and aramid fiber.

2. What is the maximum output of the braiding machine?

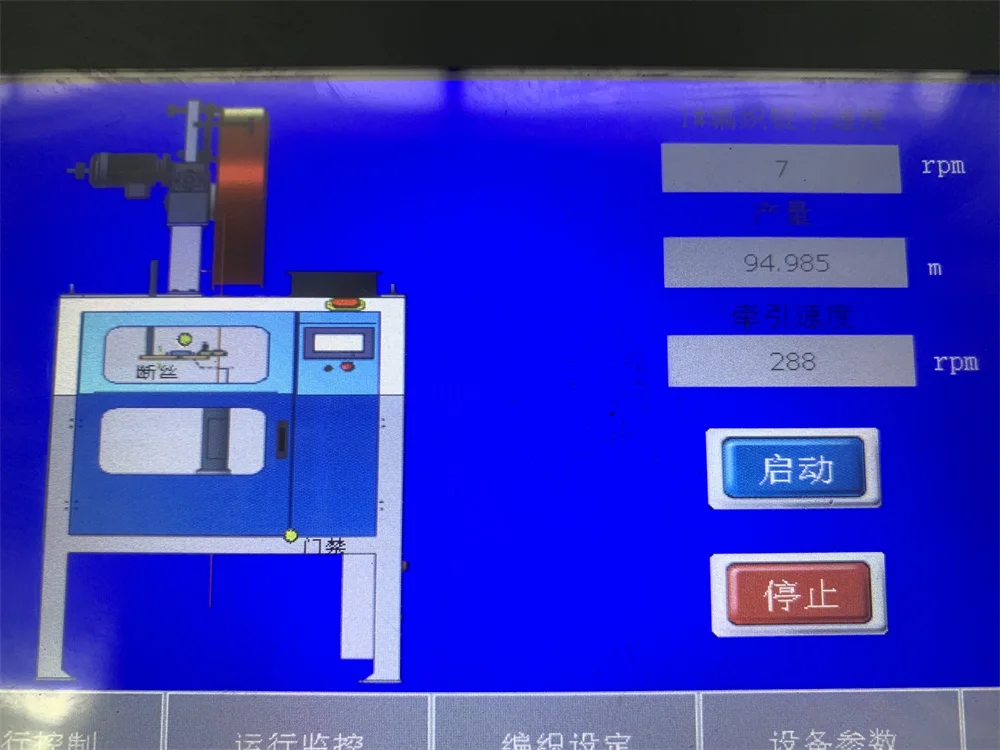

The maximum output of the machine is 98 meters per hour, which is more than three times that of commonly used models.

3. Is the braiding machine easy to maintain?

Yes, the GLT braiding machine is designed for convenient maintenance with flexible transmission, easy assembly, and disassembly of its structure.

4. What are the operating speeds for different carrier configurations?

The operating speeds are as follows: 16 Carrier at 55 rpm, 24 Carrier at 50 rpm, 36 Carrier at 36 rpm, and 48 Carrier at 20 rpm.

5. Does the machine come with an automatic shutdown feature?

Yes, the machine has a high degree of automation including an automatic shutdown feature when a wire breaks.

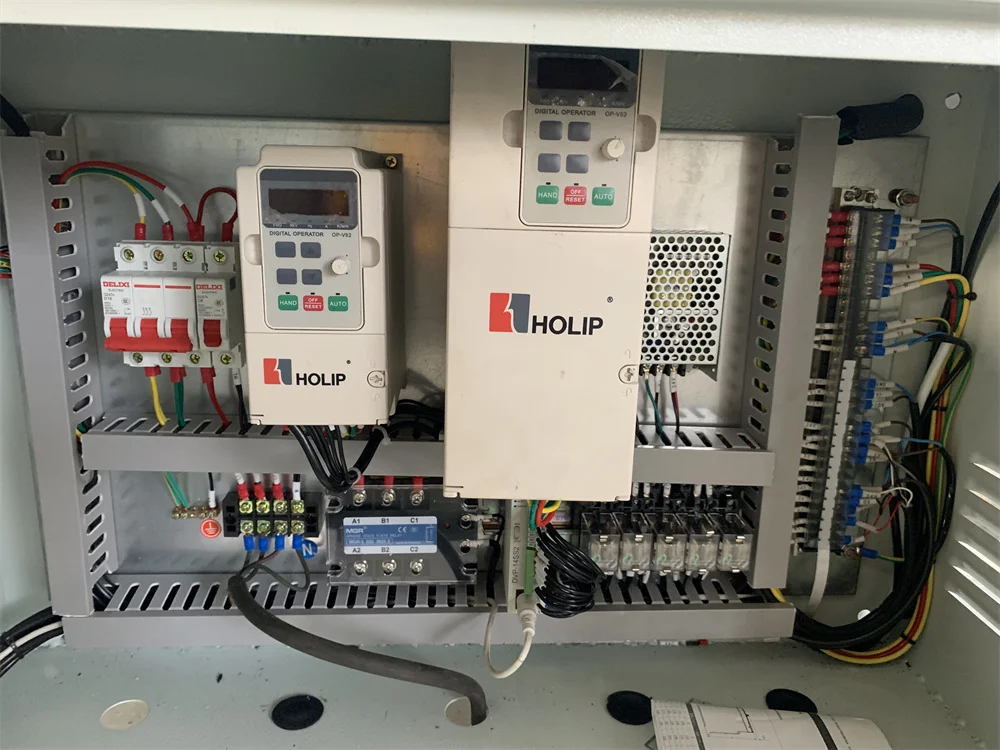

6. What is the voltage requirement for the braiding machine?

The machine operates on a 3 Phase 380V voltage, although customizations are available.

7. What types of hoses can be produced with this braiding machine?

The machine is suitable for producing various hoses including pressure-resistant braided rubber pipes, water heating braided hoses, and Teflon hoses.

8. What are the key advantages of using this braiding machine?

Key advantages include high production efficiency, low noise operation, convenient maintenance, and a long service life due to quality material and design.

9. Can I customize the machine for specific production needs?

Yes, the braiding machine can be customized for various specifications and options as per your production requirements.

10. What safety features are included in the machine?

The machine includes an empty bobbin detector and a central lubrication system to ensure safe and efficient operation.

11. What can I do if I need assistance with setup and operation?

For assistance with setup and operation, please contact our customer support team who can provide guidance and support.

12. What are the dimensions of the hoses that can be braided?

The machine can braid hoses with diameters ranging from 20mm to 48mm depending on the specific model.

13. Is there a digital display for monitoring production?

Yes, the machine is equipped with a digital production counter for monitoring output effectively.

14. What is the noise level of the machine during operation?

The machine operates at a low noise level due to its suction, shock absorption, and embedded devices designed to minimize sound.

15. Can the braiding patterns be adjusted?

Yes, the machine can produce different braid patterns including 2 over 2 and 1 over 1 configurations.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading