B21, China Town Mall, Midrand

UV DTF Printer 2 in 1 Mobile Case Boxes Printing Machine

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600817799431

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the product and which models are available?

This is the UV DTF Printer 2 in 1 Mobile Case Boxes Printing Machine. The specification sheet references model BN-604. The BN-A30 UV DTF is listed as a presale model — please contact the supplier for availability and details on presale models.

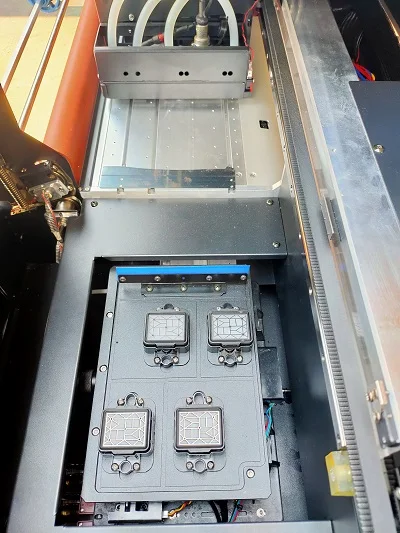

2. What printhead does the machine use and how many heads can it have?

The machine uses Epson I3200 printheads and is available with either 3 or 4 heads (head quantity options).

3. What print media and maximum width does the printer support?

The printer is designed for AB film (commonly used for DTF workflows) and supports media up to 600 mm wide.

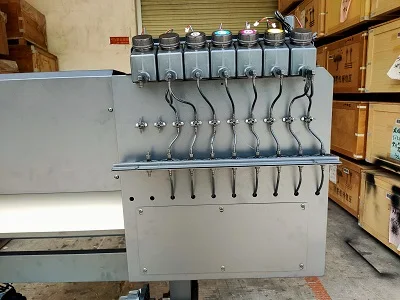

4. What kind of ink does the machine use?

This model uses UV DTF special ink formulated for the UV DTF workflow and high-capacity ink supply is supported.

5. What are the printing speeds?

Listed speeds are approximately 6 PASS at 6 m²/h and 8 PASS at 4 m²/h. Actual throughput will vary by image, RIP settings, and substrate.

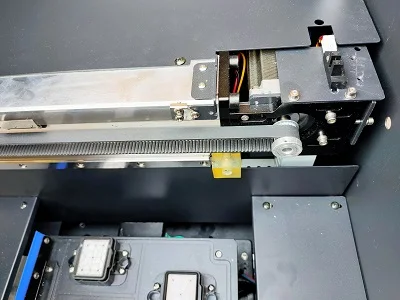

6. How does the machine handle winding/unwinding and media feeding?

The machine features an unbiased winding system and a dual-power retractable (retractable) system for media handling. It does not use a pinch roller platform, which helps avoid pressure marks on the film.

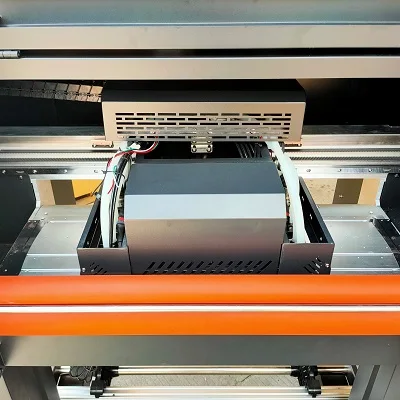

7. Is there heating or laminating capability?

Yes — the unit includes constant-temperature heating for the laminating film (automatic) and upper and lower rubber roller heating to assist fixation and curing.

8. What connectivity and file formats are supported?

Transmission is via a gigabit network interface. Supported file formats include PDF, JPEG, TIFF, etc. The recommended RIP software is Maintop 6.1 (also lists PP and PF compatibility).

9. What are the electrical requirements and power consumption?

The machine requires 220 V power and has a listed machine power of 1000 W.

10. What are the machine dimensions and shipping weight?

Machine size is 1700 × 850 × 1420 mm (L×W×H). Packing size is 1800 × 900 × 750 mm. Gross/net weight is listed as 255 kg.

11. How does the intelligent ink detection system work and what benefits does it provide?

The intelligent ink detection system monitors ink levels and ink status to help prevent nozzle dry-out and reduce downtime by alerting the operator to low or abnormal ink conditions. For detailed operation and thresholds consult the user manual or supplier.

12. What does 'no pinch roller platform' mean and why is it beneficial?

'No pinch roller platform' means the printer does not use heavy pinch rollers that press directly on the media surface. This reduces risk of pressure marks or deformation on delicate films and certain finished substrates — useful when printing on film for transfers or thin media.

13. Is the operation interface easy to use?

The printer includes a smart operation panel for machine control and settings. For full walkthroughs and training options, contact the supplier for user guides or demonstration.

14. What maintenance is required for the printheads and the machine?

Routine maintenance typically includes printhead cleaning cycles, checking/refilling ink, keeping the heating/laminating rollers clean, and periodic inspection of the retractable and winding systems. Follow the manufacturer's maintenance schedule in the user manual to ensure printhead longevity and consistent output.

15. What support, warranty and purchasing information is available?

Warranty terms and after-sales support are not specified in the listing. For pricing, warranty, lead times (including BN-A30 presale model), spare parts, and local service options, please contact the supplier or your sales representative.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading