B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Shoe Upper Knitting Machine?

The Shoe Upper Knitting Machine is designed to produce high-quality shoe uppers and various knitted items such as belts, hats, scarves, sweaters, collars, and underwear.

2. What is the power rating of the Shoe Upper Knitting Machine?

The machine is equipped with a powerful motor that operates at 1700 W, providing robust performance for demanding knitting tasks.

3. What are the available bed widths for this machine?

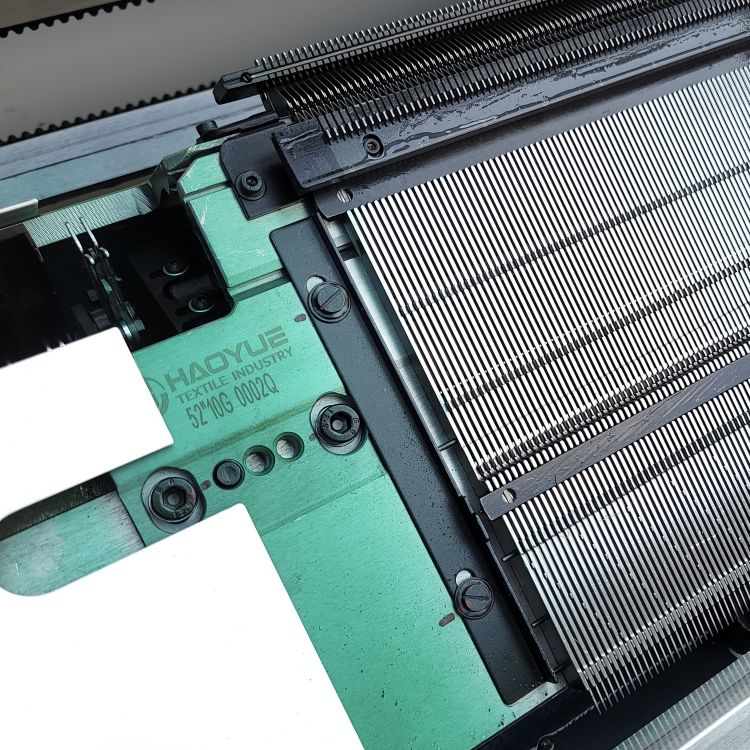

The Shoe Upper Knitting Machine has a standard bed width of 36 inches, with additional models available in widths ranging from 36 to 80 inches.

4. What gauge options are available for the knitting machine?

The machine offers adjustable gauges of 12g, 14g, and 16g, allowing for different fabric densities based on your project needs.

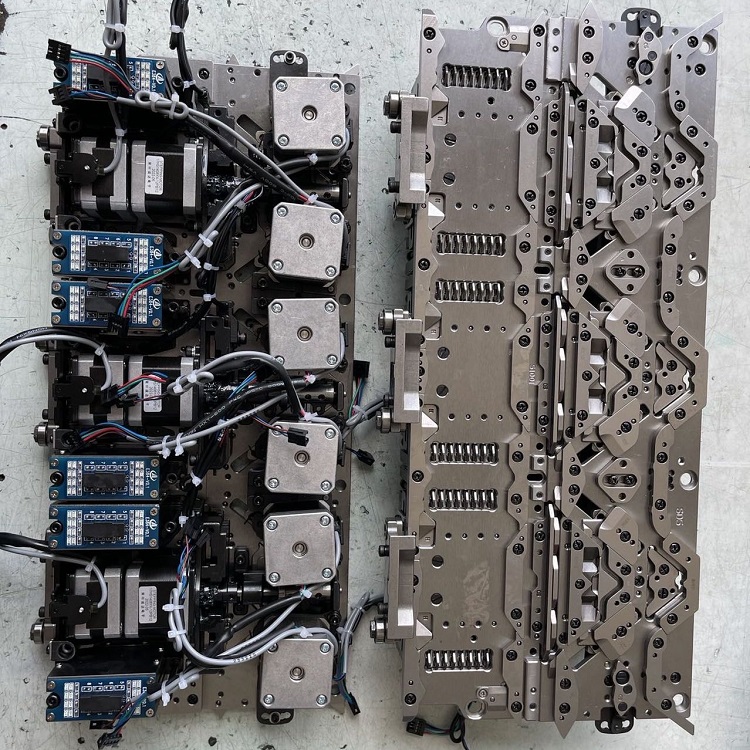

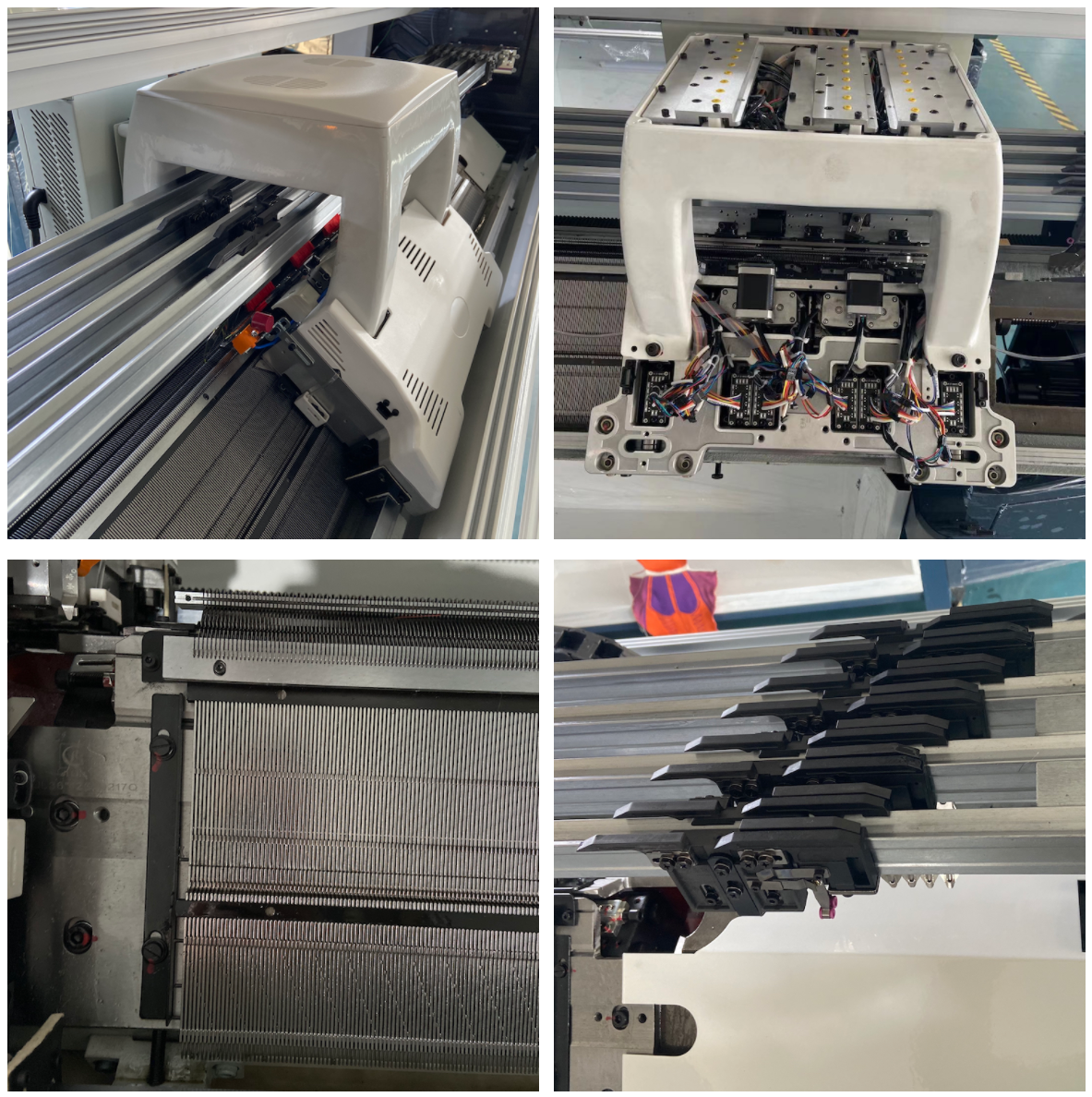

5. How does the single carriage knitting system work?

The machine features a single carriage with three knitting systems that can operate together or separately, enhancing productivity while allowing for complex knitted patterns.

6. What are the dimensions of the Shoe Upper Knitting Machine?

The machine has compact dimensions of 2300 mm x 900 mm x 1700 mm, making it suitable for various workshop setups.

7. Is the Shoe Upper Knitting Machine easy to maintain?

Yes, the machine is designed for easy maintenance and comes with a machinery test report to ensure high standards, minimizing downtime.

8. What types of patterns can the machine knit?

The machine can knit a wide range of patterns including transfer, tuck, pointelle, intarsia, jacquard, and irregular multi-colored designs.

9. How does the dynamic stitch function work?

The dynamic stitch function allows the machine to knit a wider range of patterns and different densities on the same line, creating more 3D effects.

10. What is the maximum knitting speed of the machine?

The machine can achieve a maximum knitting speed of 1.6 m/s, which can be increased by 20-30% with high-speed reversal.

11. Does the machine support color changing?

Yes, the machine features a color-changing system that can execute color changes via motor, allowing for various design options.

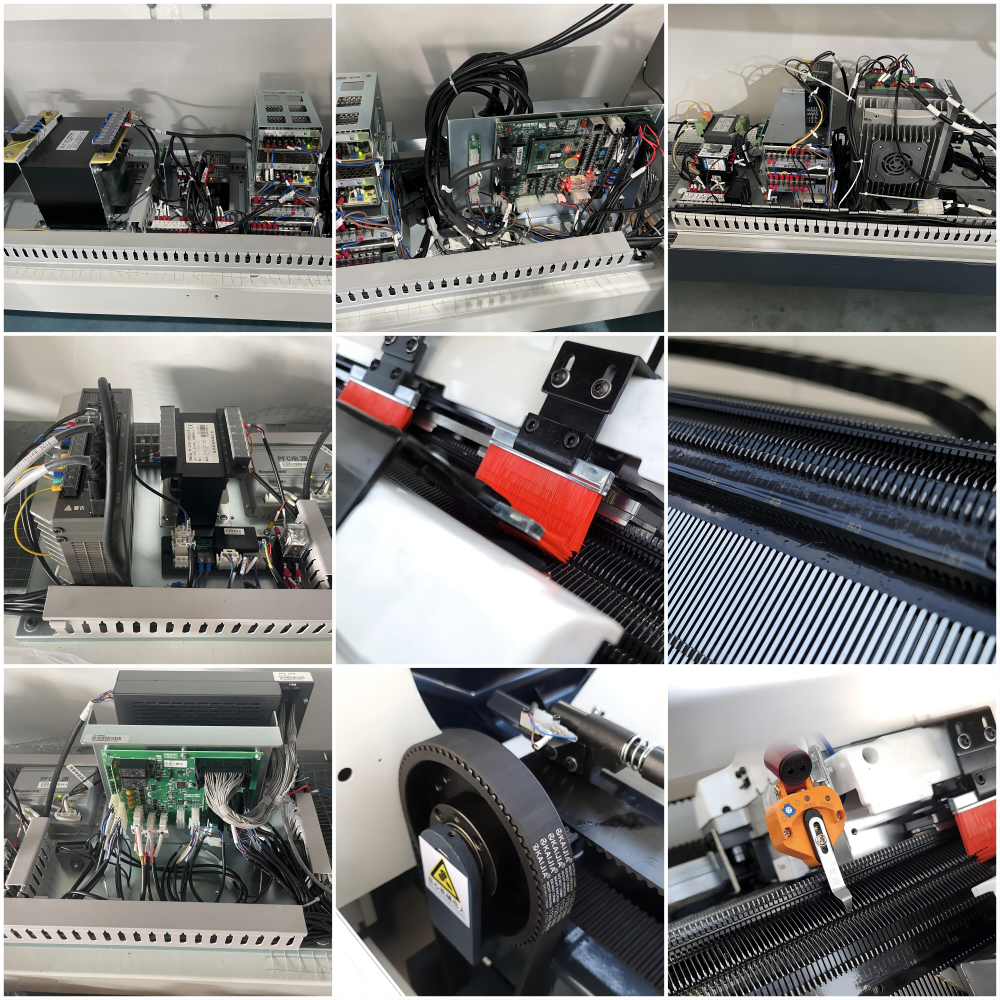

12. What type of control system does the machine have?

The machine is equipped with an LCD industrial display for parameter adjustments, a USB memory interface, and supports multiple languages including Chinese, English, Spanish, and Russian.

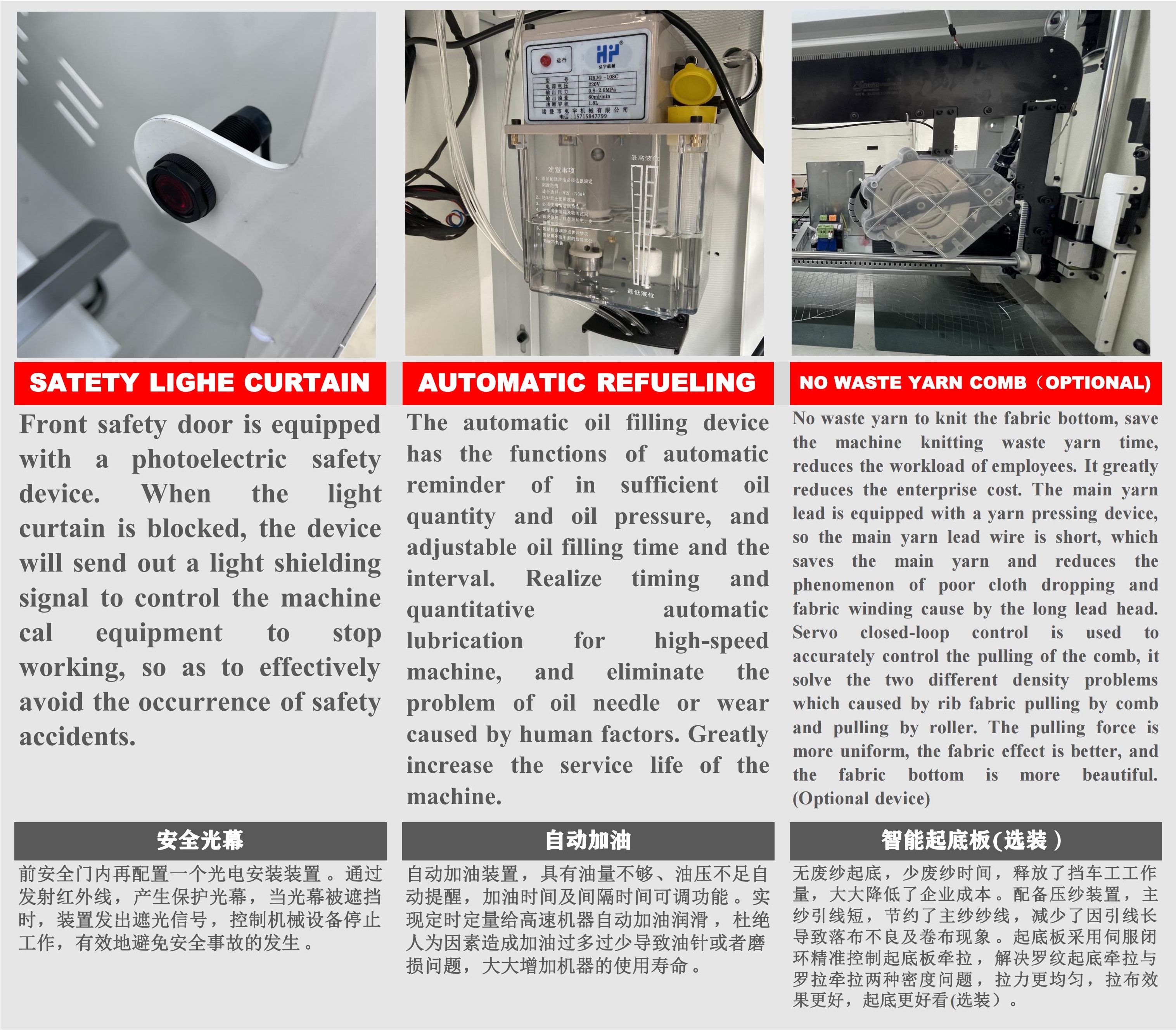

13. What safety features does the machine include?

The machine has an automatic alarm system that detects issues such as yarn-breaking, knots, and needle breakage, along with a safety auto-lock protection device.

14. Can the machine connect to a network?

Yes, the machine has a network interface that enables remote monitoring and connection with ERP systems.

15. What power supply options are available for the machine?

The Shoe Upper Knitting Machine can operate on a single-phase 220V or three-phase 380V power supply.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading