B21, China Town Mall, Midrand

SANY 710 Underground Coal Mine Drilling Machine of Coal Mining Equipment List

- Section : Machinery

- Category : Mining Machinery

- SKU : 62015332824

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the SANY 710 Underground Coal Mine Drilling Machine?

The SANY 710 Underground Coal Mine Drilling Machine is designed for drilling operations in underground coal mining, facilitating the extraction process by creating drill holes for blasting and other mining activities.

2. What are the key features of the SANY 710 drilling machine?

Key features include a highly reliable hydraulic system, high-reliability electric system, advanced electric control system, modularity for easy maintenance, and a black box data storage system for operational tracking.

3. How does the hydraulic system in the SANY 710 improve efficiency?

The hydraulic system utilizes a duplex pump setup with a large displacement pump for height adjustment and a small displacement pump for braking, minimizing power loss and enhancing overall efficiency.

4. What is the maximum operating temperature for the oil in the hydraulic system?

The oil temperature in the hydraulic system is maintained below 50℃, thanks to a fin-type cooler installed in the oil return pipeline.

5. Can the SANY 710 drilling machine be adapted for different mining conditions?

Yes, the SANY 710 features high modularity and interchangeable components, allowing mine owners to adjust the machine's performance to meet specific mining needs at a low cost.

6. What safety features are included in the electric system?

The electric system includes a shock test and inspection for electric components, as well as a complete intelligent self-diagnostic system that provides failure locating and warning functions.

7. What is the significance of the multi-sensor shock test analytic technology?

This technology effectively controls the shocks of all shafts in the engagement direction, which enhances the stability and reliability of the drive system during operation.

8. How does the SANY 710 handle high inclination working conditions?

The machine employs a quadrant control strategy developed through extensive testing and analysis to ensure optimal performance in high inclination working conditions.

9. What are the different models available in the SANY 710 series?

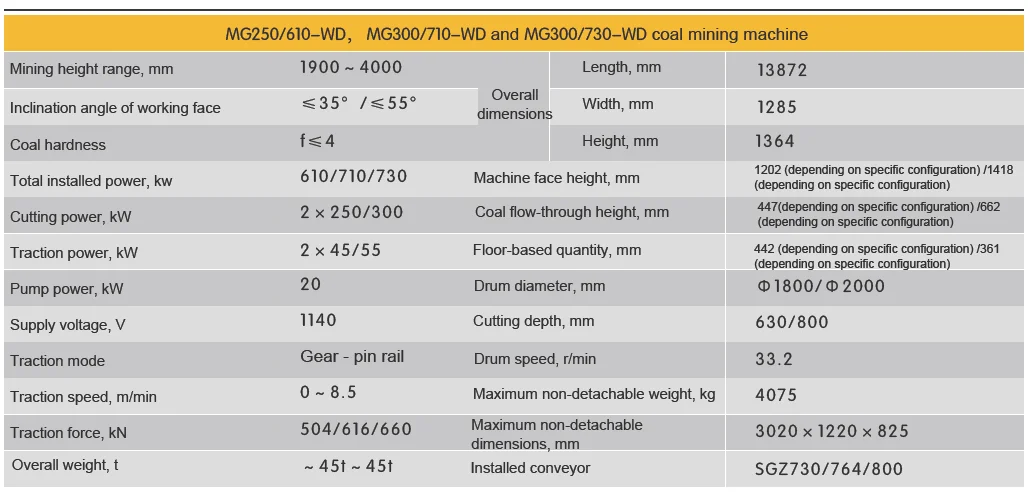

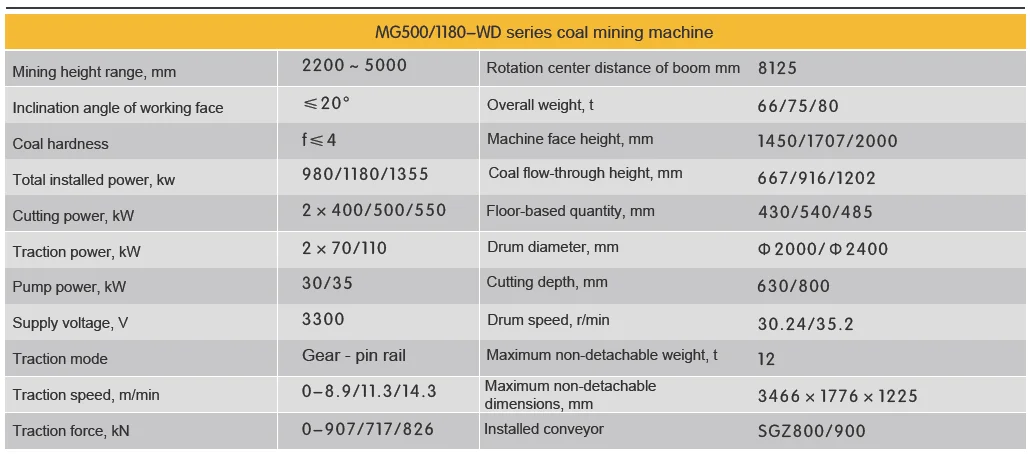

The SANY 710 series includes models such as MG250/610-WD, MG300/710-WD, and MG300/730-WD, each with varying mining height ranges and yearly output capacities.

10. What is the yearly output capacity of the SANY 710 drilling machine?

The yearly output capacity varies by model, ranging from 150,000 to 400,000 tons, depending on the specific equipment model selected.

11. What is the machining accuracy of the housing in the SANY 710?

The housing is finish machined using imported machining centers to ensure perfect dimensional tolerances and roughness, guaranteeing the proper functioning of the drive system.

12. How does the black box data storage system work?

The black box data storage system records all operational data during the machine's running time, including failure memory, which can be referenced for diagnostics and analysis.

13. Is maintenance easy for the SANY 710 drilling machine?

Yes, the design includes a high-integrated and modularized main control cabinet and inspection cabinet for easy maintenance and integral replacement of components.

14. What types of applications can the SANY 710 drilling machine be used for?

The SANY 710 can be utilized for a variety of applications in coal mining, including drilling for blasting, creating ventilation pathways, and facilitating the extraction of coal from underground seams.

15. What measures are in place to ensure the reliability of electric components?

The electric components undergo rigorous shock testing and inspection to ensure that they can withstand operational stresses and maintain reliability during use.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading