B21, China Town Mall, Midrand

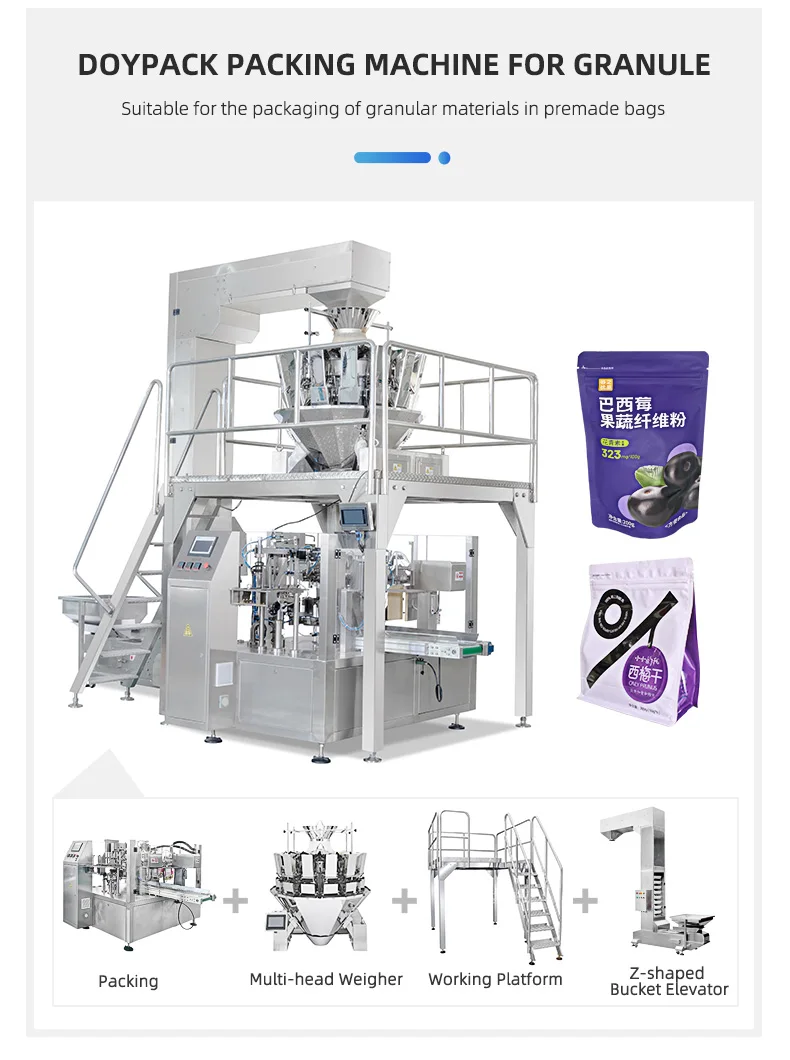

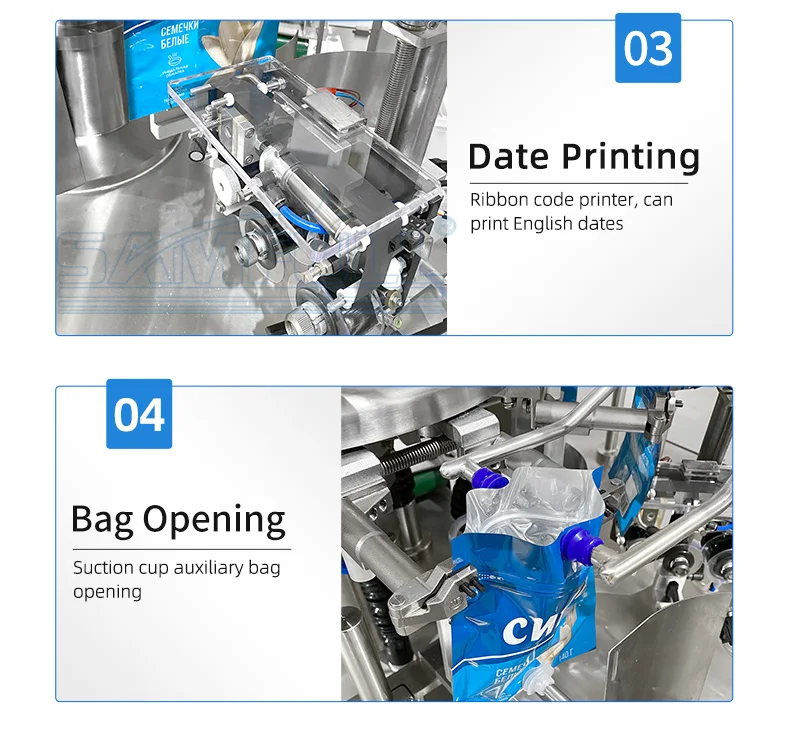

Samfull Full Automatic Rotary Doypack Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600776760871

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 18 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum production speed of the Samfull Full Automatic Rotary Doypack Packing Machine?

The machine can run up to 40 bags per minute. Typical practical speeds range from about 15 to 40 bags/min depending on product characteristics, bag size, filling method and machine configuration.

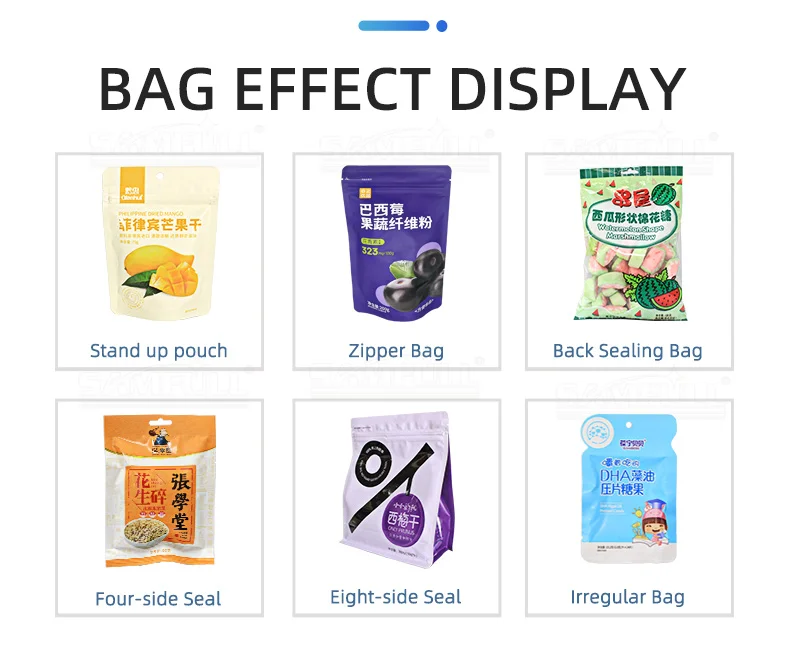

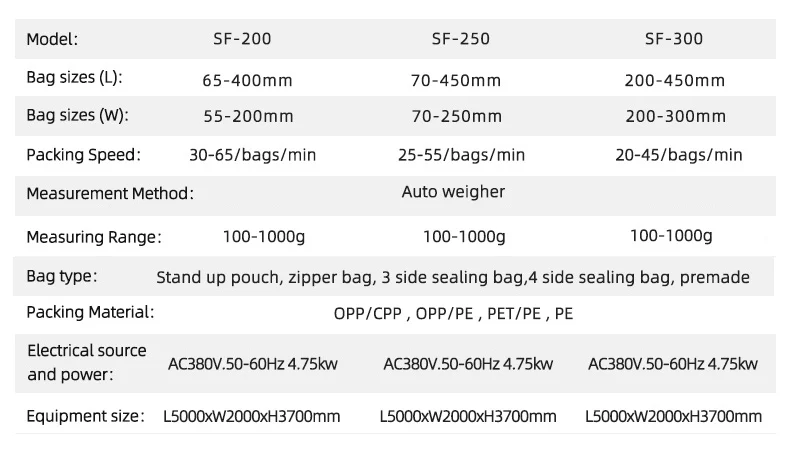

2. What bag types and sizes are supported?

It handles pre-made bags and doypack (stand-up) bags. Supported bag lengths range from 120 mm to 330 mm and widths from 80 mm to 200 mm.

3. What filling weights can the machine handle?

The filling range is 100 g to 1000 g. For very small or very large fills, please discuss your product with sales for optimal configuration.

4. Which kinds of products can be packaged with this machine?

It is designed for a wide range of applications including food, beverages, commodities and chemicals. With proper filling modules (auger, multi-head weigher, pump, piston, etc.) it can handle powders, granules, small solids and many liquids/viscous products.

5. What material is the machine constructed from and is it food-safe?

The machine is built from food-grade SUS304 stainless steel, meeting typical hygiene requirements for food industry applications.

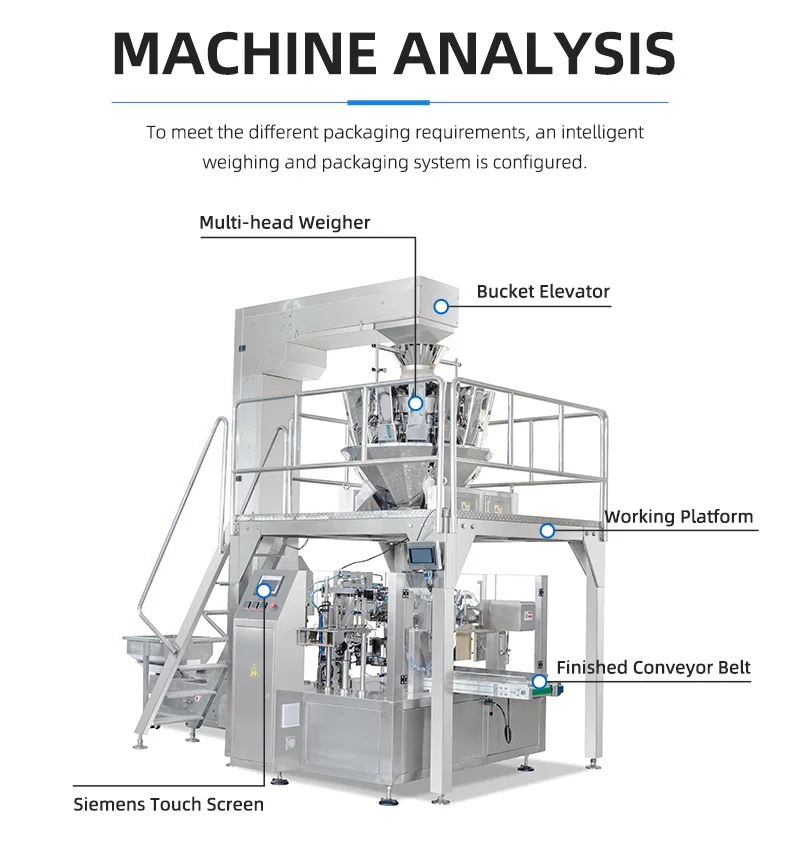

6. Can the machine be integrated with other equipment?

Yes. It can be combined with equipment such as multi-head weighers, Z-type elevators, feeding systems and working platforms to create a complete automated packaging line.

7. What type of testing and inspection is provided before shipment?

Each machine ships with a machinery test report and outgoing inspection video to demonstrate performance and quality prior to delivery.

8. What warranty and after-sales support are provided?

The machine comes with a 1-year warranty on the entire unit. After-sales support includes technical assistance, spare parts supply and guidance for installation and commissioning.

9. How easy is the machine to operate and maintain?

The machine is fully automatic and engineered for easy operation. Routine maintenance includes regular cleaning, inspection of wear parts, lubrication of moving components and following the provided maintenance schedule and manual.

10. Are spare parts and consumables readily available?

Yes. Common wear parts and consumables are available through the manufacturer or authorized distributors. For high-usage items we recommend stocking critical spares locally.

11. What electrical or utility requirements does the machine have?

Electrical, air and other utility requirements can vary by configuration. Please request the machine's technical datasheet or contact the supplier with your preferred model so exact power and pneumatic specs can be confirmed.

12. Is on-site installation and operator training provided?

Installation and operator training options are typically available—either remote or on-site—depending on your location and purchase agreement. Confirm availability and terms with the supplier.

13. Can the machine be customized for specific product or bag features?

Yes. The machine can be customized with different filling systems, dosing mechanisms, bag handling fixtures and optional accessories to suit your product, bag style or production requirements.

14. How do product characteristics affect machine performance?

Throughput and accuracy depend on product flow properties (free-flowing vs. cohesive), particle size, moisture content, bag size and target fill weight. Proper feeder/filler selection and line tuning optimize performance for each product.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading