B21, China Town Mall, Midrand

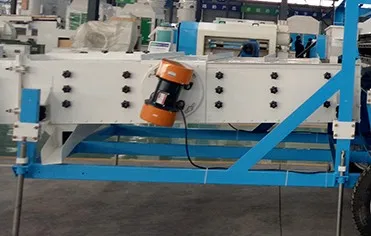

Red Kidney Bean Cleaning Machine Cleaner Barley lentil bean maize cleaning and grader Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600951003766

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this machine used for?

The Red Kidney Bean Cleaning Machine (mobile seed cleaner and grader) is used to clean and grade seeds, grains, spices and crops such as red kidney beans, barley, lentils, maize/corn, wheat, rice, sunflower seed, oilseeds, chili and vegetable seeds by removing dust, awns, husks, chaff, broken and diseased seeds and separating by size and density.

2. What cleaning and separation technologies does the machine use?

It combines a broken-proof bucket elevator, dual air suction/blower system with cyclone dust collector, de-awner, vibration cleaner/grader, and a gravity (density) table to remove light impurities, large impurities, broken seeds and separate by density and size.

3. What is the processing capacity?

Rated capacity ranges from 5 to 20 t/h (based on wheat). Model-specific: 5XFZ-7.5 — 7.5 t/h (wheat) and 5 t/h (rice); 5XFZ-10 — 10 t/h; 5XFZ-20 — 20 t/h (wheat) and up to 15 t/h (corn). Actual capacity varies with crop, moisture and feed conditions.

4. What cleaning performance can I expect?

Typical performance figures are selection rate ≥98%, cleanness rate ≥99% and broken rate ≤0.5%, depending on crop and operating settings.

5. What are the machine dimensions, weight and mobility features?

Dimensions vary by model: 5200×2340×3560 mm, 5600×2340×3560 mm, and 6000×2350×3560 mm. Total weights are approximately 2100 kg, 2600 kg and 3500 kg respectively. The unit is mobile with wheels and a traction frame; travel speed is under 10 km/h for towing.

6. What power and motor specifications are required?

Total installed power is approximately 15.35 kW, 17.35 kW or 17.55 kW depending on model. A huller motor (optional) is 7.5 kW. Exact voltage and electrical specifications should be confirmed with the supplier to match local supply.

7. How does the machine manage dust and provide a clean working environment?

A dedicated air suction system with top and bottom blowers and a cyclone dust collector removes light impurities and dust from the airflow, improving cleaning efficiency and reducing dust in the work area.

8. How does the gravity table work and what does it remove?

The gravity (density) table uses differences in specific gravity and vibration to separate heavier healthy seeds from lighter impurities such as stones, blighted, diseased, moldy and insect-damaged seeds. The table area is about 3.7 m² to allow effective separation.

9. How many output streams does the machine provide?

The machine classifies and discharges seeds by size and quality to different outlets (e.g., cleaned seed, oversize, undersize, light impurities and waste) based on screening, grading and gravity separation stages.

10. Is the machine suitable for red kidney beans, lentils and maize?

Yes. The unit is designed for a wide range of small-particle products including red kidney beans, lentils and maize/corn. Settings (screens, airflow, gravity table adjustment) should be optimized for each crop for best results.

11. What routine maintenance is required?

Regular tasks include cleaning screens and cyclones, checking and tightening belts and fasteners, greasing bearings, inspecting and replacing worn screens or rubber parts, verifying blower and motor operation, and keeping the electric control box connections clean and dry.

12. Are spare parts and after-sales support available?

Standard wear parts (screens, belts, blowers, bearings, control components) are typically available from the manufacturer or supplier. For warranty, spare parts and service availability, contact the supplier or dealer directly for terms and lead times.

13. How is the machine delivered and installed? Is operator training provided?

The machine is provided as a mobile unit and is largely assembled. Minor on-site setup and electrical hookup may be required. Many suppliers offer installation assistance and operator training—confirm these services at purchase.

14. What safety precautions should operators follow?

Follow lockout/tagout before maintenance, keep guards in place, wear appropriate PPE (masks, hearing protection, gloves), avoid loose clothing near moving parts, ensure proper grounding of the electrical system, and follow the supplied operation manual and local safety regulations.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading