B21, China Town Mall, Midrand

| Quantity | Price |

|---|

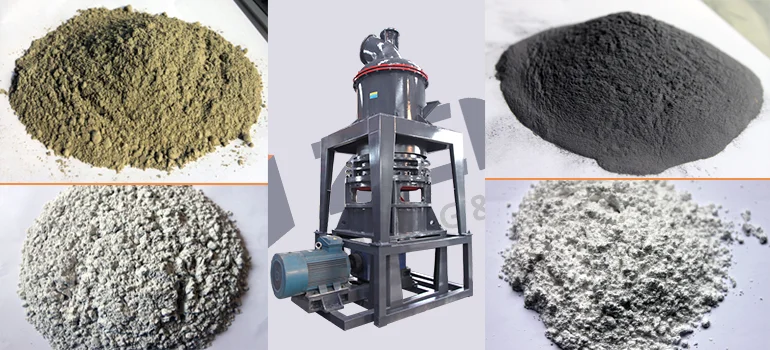

Produce micro-scale stone powders down to 2500 mesh with the high-performance ZENITH stone super fine grinding mill. Ideal for ultra-fine mining applications, it delivers precisely-milled particulates.

Typical finenesses range from 2500-3250 mesh, meeting demands from industries like ceramics, paints, battery production and healthcare that require extremely fine mineral powders.

Inside the intelligent micro-grinding system, multiple grinding chambers equipped with centrifugal micro-fluitization technology pulverizes stones into uniform ultra-micro particles. Unlike other mills, it ensures over 90% of products are below 2500mesh.

Processing up to 1-5 tons per hour depending on feed material, the machine guarantees large-volume manufacturing of high-value super fine powders. Automated functions optimize milling efficiency while lowering operating costs.

Backed by its industry-leading fineness capabilities, contact ZENITH to boost output of your micro-scale production. The grinding mill sets a new standard for industrial ultra-fine powder generation.

Use Range: can be used in more than 300 kinds of stone materials powder grinding, such as: calcite, calcium carbonate, dolomite, gypsum, carbon black, gypsum, kaolin, marble and so on

Product Description

China Famous Small Raymond Mill Fine Powder Processing Machine Mineral Equipment With Capacity 10-35 Tph Advantages

Ultrafine Powder

The fineness can be adjusted between 325-2500 meshes, and the screening rate can achieve D97≤5μm once. | Higher Capacity With the same fineness and power, the capacity is 40% higher than that of jet grinding mill and stirred mill, and the yield is twice as large as that of ball mill. |

| Continuous Operation The lubricating device is installed outside of the main shaft, so that lubrication without shutdown can be realized, and the production can be continued for 24h. | Eco-friendly Production Silencer and noise elimination room are configured to reduce noises. Besides, the operation is organized by conforming to national environmental protection standards. |

fine powder processing machine introduction:

Zenith fine powder processing machine is widely used in making fine powder or micro powder, a new kind of machine for producing ultrafine powder. grinding machines in pakistan is mainly used for grinding the material with middle and low hardness, moisture below 6%, and the material should be non-explosive and non-flammable, such as: calcite, chalk, limestone, dolomite, kaolin, bentonite, steatite, mica, magnetite, iolite, pyrophillite, vermiculite, meerschaum, attapulgite, diatomite, barite, gypsum, alunite, graphite, fluorite, phosphate ore, potassium ore pumice, etc. The size of the finished product from fine grinder pulverizers can be adjusted between 325-2500 mesh.

fine powder processing machine working principle

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, edge of then evenly sent to the upper distribution plate of the turnplate by vibrating feeder and sloping feeding pipe. When the grinding machines in pakistan is at work, all the grinding rollers are rolling in the ring, and the materials are driven to the edge of the turnplate by the centrifugal force and fall down into the grinding chambers where the materials are repeatedly pressed, crushed and grinded by the rollers.The high-pressure air blowepowder gypsum production liner constantly inhales air within the grinding machines in pakistan and, in turn, the air flow with crushed materials are brought to the classifier whose high-speed impeller will screen the airflow: the unqualified particle size will fall and return to the grinding machines in pakistan for being reground while the qualified particle size mixed with air will go into the cyclone powder collector. of the qualified powders will fall an exit from the discharging valve at the bottom; a small proportion of the fine powders, with airflow, moves to the dust cleaner, and clings to the surface of the filter bags. At the same time, the fine powders clinging to the surface fall down by the sudden vibration of the filter bags, which is caused by the instantly ejected high-pressure gas controlled by the pulse valve. The materials from the above two lots are sent by the conveyor at the bottom to get finished powders packed. In addition, filtered clean air will be emitted from the air outlet of muffler in the end.

fine powder processing machine Features:

1.High pressure spring design.

2.Smoothly vibration reduce design

3.Convenient vane adjust design.

4.The machine has a strong material applicability , which suits for many kinds of material whose Moh’s hardness is less than 9.3.

5.Grinding device adopts superimposed multistage seal, sealed performance is good.

fine powder processing machine application

fine powder processing machine is widely used in many industrial fields, such as building, chemical, chemical fertilizer, metallurgy, mining, nonmetal,abrasive, bearing materials, ceramic, steel, thermal power, bricks & tiles, coal industry, etc. It can grind these materials which are 9 or less on the Meshesscale, and moisture is below 6%., and they should be non-explosive and non-flammable mining materials. The final size can be adjusted from 30 to 400 meshes easily.There are thousands of materials our mtm power can grind.

fine powder processing machine Technical Data:

| Model | Number of roller (piece) | Ring diameter (mm) | Number of ring (piece) | Max. inlet size (mm) | Final size (mesh) | Capacity (kg/h) | Main equipment rotate speed (r/min) |

| XZM221 | 21 | Φ800 | 3 | ≤10 | 325-2500 | 600-5500 | 235 |

| XZM224 | 24 | Φ900 | 3 | ≤20 | 325-2500 | 700-5500 | 235 |

| XZM236 | 36 | Φ1000 | 4 | ≤20 | 325-2500 | 700-7500 | 235 |

| Basic data | Item | Unit | specification | ||

| XZM221 | XZM224 | XZM236 | |||

| Motor of main machine | Model | - | Y250M-4 | Y280S-8 | Y2-315L-6 |

| Power | kw | 55 | 37×2 | 110 | |

| Speed-adjustable motor | Model | - | Y180M-4 | Y180L-4 | Y2VP200L-4 |

| Power | kw | 18.5 | 22 | 30 | |

| Motor of elevator | Model | - | Y100L-4 | Y100L-4 | Y100L-4 |

| Power | kw | 3 | 3 | 3 | |

| Motor of blower | Model | - | Y225M-2 | Y225M-2 | Y280S-2 |

| Power | kw | 45 | 55 | 90 | |

| Hammer crusher | Model | - | PC300*400 | PC300*400 | PC400*600 |

| Power | kw | 11 | 11 | 18.5 | |

| Electromagnetic Vibrating feeder | Model | - | GZ1F | GZ1F | GZIF |

| Power | kw | 0.06 | 0.06 | 0.06 | |

| Discharge valve | Model | - | ZJD-200 | ZJD-200 | ZJD-200 |

| Power | kw | 0.75 | 0.75 | 0.75 | |

| Note: If there is any change of above specification, it is all according to the booklet with machine. |

At Afrimart, we strive to process all orders promptly. Once the payment has been successfully cleared into our account, your order will be processed within 2 to 5 business days. Please note that this processing time excludes weekends and public holidays.

Following the processing of your order, the estimated delivery lead time ranges between 35 to 60 days. However, please be aware that this timeframe is subject to variations due to potential delays in shipping and customs clearance. While we aim to adhere to the original delivery schedule, unforeseen circumstances may occasionally extend the delivery window beyond the anticipated 35 to 60 days.

In the event of high demand or other factors leading to longer shipping times for certain items, we will communicate any expected delays during the initial order confirmation. We appreciate your understanding and patience as we work to ensure your order arrives as swiftly as possible.