B21, China Town Mall, Midrand

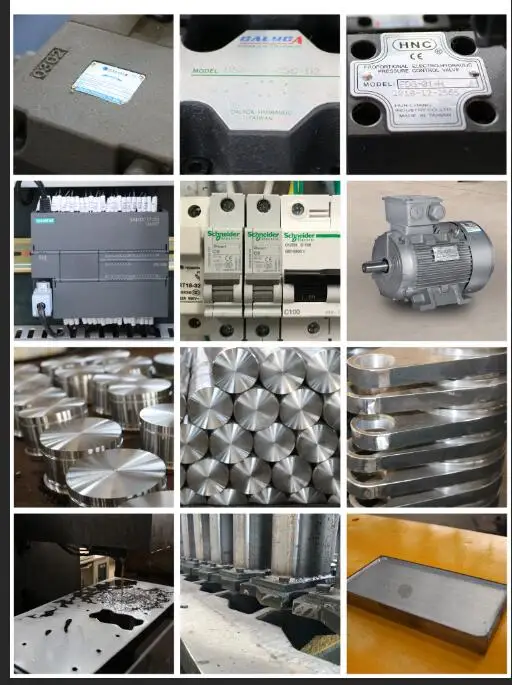

QT4-25 Interlock Hollow Block Paver Making Machine.

- Section : Machinery

- Category : Brick Making Machinery

- SKU : 1600171424998

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the production capacity of the QT4-25 Interlock Hollow Block Paver Making Machine?

The production capacity varies depending on the size of the blocks. For example, it can produce 360 to 450 pieces of 1400*200*200mm blocks per hour.

2. How much space is required to operate the QT4-25 machine?

A minimum of 60 square meters of workshop area is required to operate the QT4-25 Interlock Hollow Block Paver Making Machine.

3. What is the moulding period for the QT4-25 machine?

The moulding period for the QT4-25 machine is approximately 24 seconds.

4. Is the QT4-25 machine easy to operate?

Yes, the QT4-25 is designed for easy operation and maintenance, making it suitable for users with minimal experience.

5. What types of bricks can be produced with the QT4-25 machine?

The QT4-25 can produce various types of bricks, including hollow bricks, solid bricks, paving bricks, and curbstones. Different moulds can be used to customize brick shapes and sizes.

6. How many workers are needed to operate the QT4-25 machine?

A minimum of 2 workers is needed to meet the production requirements for the QT4-25 Interlock Hollow Block Paver Making Machine.

7. What is the total power requirement for the QT4-25 machine?

The total machine power requirement for the QT4-25 is 22.05 KW.

8. Can the QT4-25 machine be used in different environmental conditions?

Yes, the QT4-25 can operate in different seasons and environments. With proper maintenance, its service life can reach 15-20 years.

9. Does the QT4-25 machine require special kilns or chimneys for brick production?

No, the bricks produced by the QT4-25 do not require a fire process, which eliminates the need for special kilns and chimneys, saving energy and space.

10. What is the vibration frequency of the QT4-25 machine?

The vibration frequency of the QT4-25 machine ranges from 4500 to 5100 times per minute.

11. How is the QT4-25 machine maintained?

Maintenance involves regular cleaning of the mixer and machine components, checking the oil levels, and ensuring proper operation protocols are followed.

12. What makes the QT4-25 machine cost-effective?

The QT4-25 machine is cost-effective due to its low initial price, minimal installation requirements, and the potential for profitability within six months of operation.

13. What is the hydraulic system rated pressure for the QT4-25?

The hydraulic system rated pressure for the QT4-25 is 15 Mpa.

14. Can the QT4-25 machine be customized for different brick sizes?

Yes, the QT4-25 machine allows for customization of brick sizes and shapes by changing the mould.

15. What is the weight of the mould and vibration platform?

The QT4-25 machine uses an upper die push-pull method and a vibration platform, but specific weights are not detailed in the product description.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading