B21, China Town Mall, Midrand

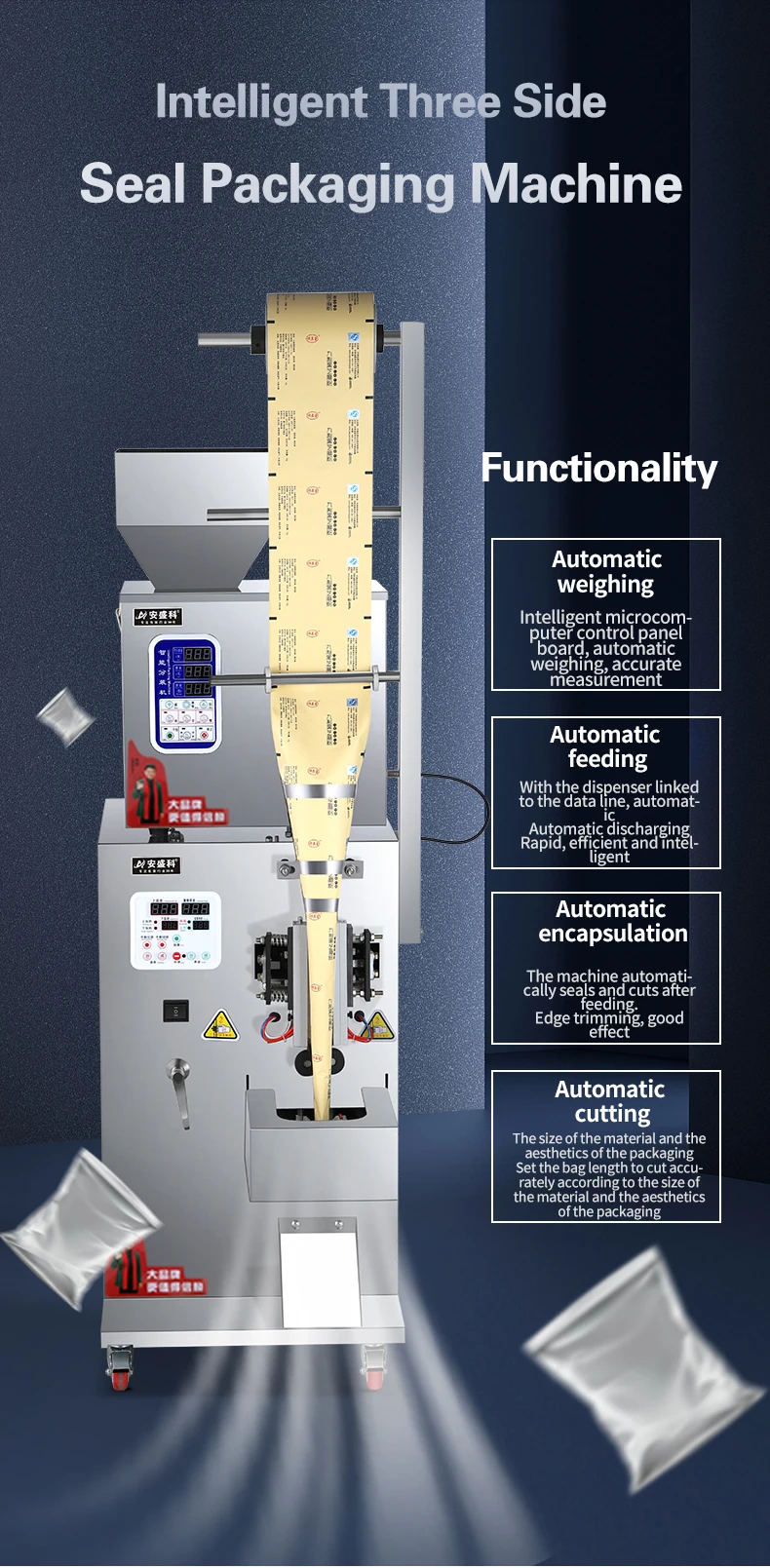

Qianshou Semi-Automatic Filling Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600958931255

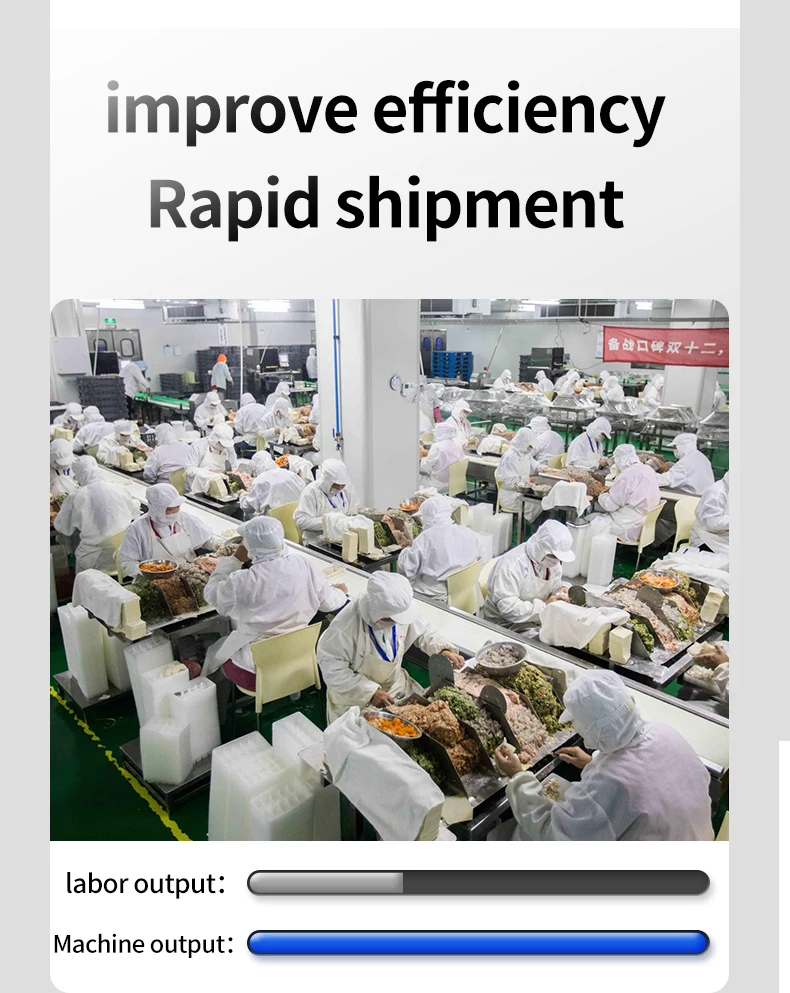

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries and products is the Qianshou Semi-Automatic Filling Machine suitable for?

The machine is designed for food, beverage and general commodity industries. It can handle a wide range of products commonly used in those sectors — including snacks, granules, powders and many liquid products — but you should confirm compatibility for specialized or abrasive products with our sales team.

2. What does "semi-automatic" mean for this machine?

Semi-automatic means the machine automates core functions (dispensing, sealing, labeling/counting where applicable) while requiring an operator for certain steps such as loading pouches, initiating cycles or changing rolls. It combines easy manual control with automated precision.

3. What is the filling accuracy of the Qianshou machine?

The machine achieves a filling accuracy of up to 99.75%, ensuring very consistent fill weights/volumes when set up and calibrated properly.

4. What is the production capacity / speed?

Typical production capacity is about 7 bags per minute, depending on product characteristics, pouch size and operator workflow.

5. What are the machine dimensions and weight?

Commonly cited dimensions vary by configuration. Typical dimensions listed are 61 cm (L) x 40 cm (W) x 104 cm (H). Another configuration shows 30 cm x 49 cm x 127 cm. Net weight is approximately 45 kg. Please confirm the exact model specification when ordering.

6. What power requirements does the machine have?

The standard driven type is electric with an operating voltage of 220V. Confirm local power standards and any optional voltages with sales before purchase.

7. Which packaging materials and pouch types are supported?

The machine is designed primarily for plastic pouch packaging and is suitable for common pouch formats used in food and commodity packaging. For unconventional films or multilayer laminates, please consult us to verify compatibility.

8. What roll film widths are available and how do I calculate required width?

Available roll widths include 6, 7, 8, 9, 10, 11, 12, 12.5, 13, 14, 15, 16, 17, 18 and 20 cm (and some listings show additional sizes such as 5 and 13 cm). To calculate required roll width, measure the finished bag width and multiply by 2. Example: for a 7 cm bag, required roll width = 7 x 2 = 14 cm.

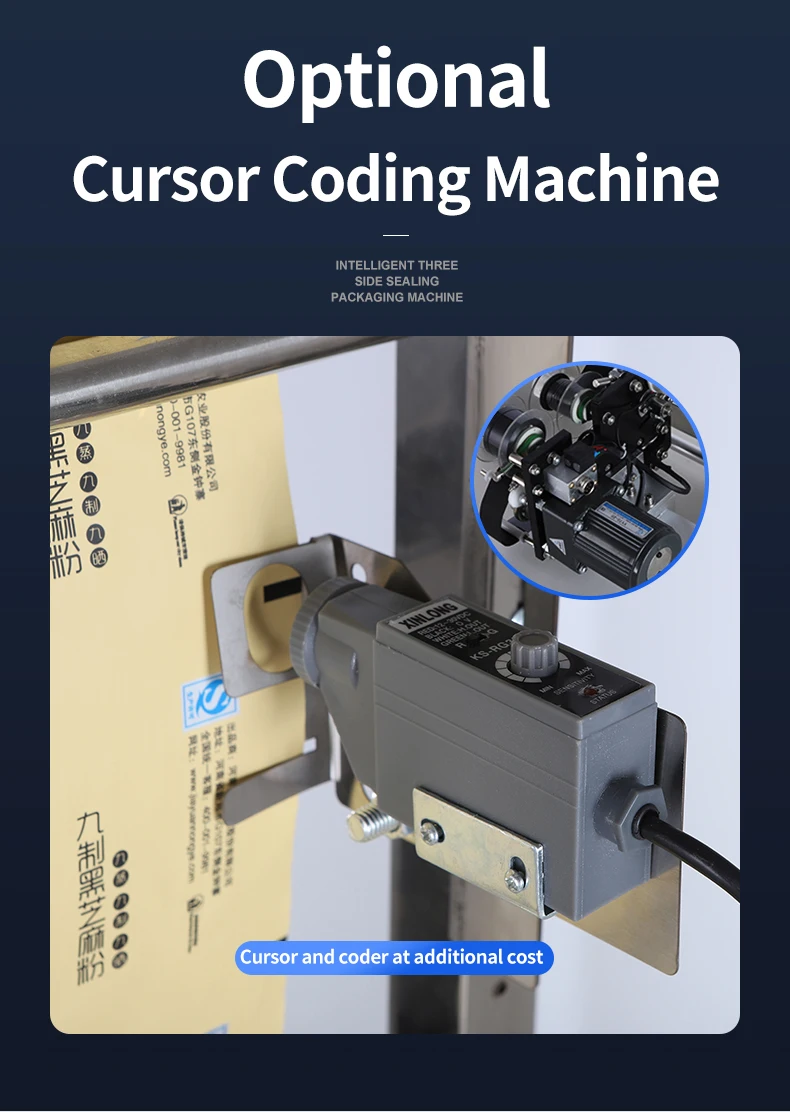

9. Is the machine customizable or available with OEM/ODM options?

Yes. The Qianshou machine supports customization and OEM/ODM services for special specifications, roll widths, and other requirements. Contact customer service to discuss customizations.

10. Does the machine support remote monitoring?

Yes. The unit can be equipped with remote monitoring features that allow operational status checks, alarms and basic remote control/diagnostics to enhance production oversight.

11. What are the main components and build quality?

Core components include a motor, pressure vessel, pump, PLC, gears, bearings and gearbox. The machine is built from robust materials for durable performance in demanding environments.

12. What warranty and after-sales support are included?

Standard warranty coverage is 1 year. After-sales support includes spare parts and service; contact customer service for details on spare part availability and extended service plans.

13. How easy is it to install and operate?

Installation is straightforward for experienced techs — basic setup includes connecting power (220V), mounting film roll and configuring settings. The semi-automatic interface is user-friendly, with quick adjustments for filling volume and seal parameters. Training is recommended for optimal performance.

14. What maintenance is required to keep the machine running reliably?

Regular maintenance includes cleaning contact surfaces, checking and lubricating moving parts, inspecting seals and film path, and periodic inspection of pump/motor and electrical connections. Follow the maintenance schedule provided in the user manual.

15. Are safety certifications and documentation available?

Safety features and documentation are provided, and specific certifications (CE, UL, etc.) can be supplied upon request depending on model and customer requirements. Please request required certificates when placing an order.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading