B21, China Town Mall, Midrand

Categories

-

Appliances

Commercial Appliances

Household Appliances

Kitchen Appliances

Major Appliances

-

Bags & Shoes

Men’s Luggage Bags

Men’s Shoes

Women’s Bags

Women’s Shoes

-

Beauty & Personal Care

Beauty Equipment

Hair Products

-

Computers

Computer Accessories

Networking

Storage Devices

-

Consumer Electronics

Camera & Photo

Home Audio & Video

Portable Audio

Printing Equipment

-

Electrical & Tools

Tools & Hardware

Electrical Equipment

-

Furniture

Commercial Furniture

Decorations

Bedroom Furniture

Dining Room Furniture

-

Kids & Toys

-

Machinery

Material Handling

Construction Machinery

Industrial Machinery

Agriculture Machinery

-

Medical Supplies

Household Medical Devices

Professional Medical Devices

Medical Consumables

Animal & Veterinary

-

Men's Fashion

Men’s Bottoms

Men’s Clothing

Men’s Accessories

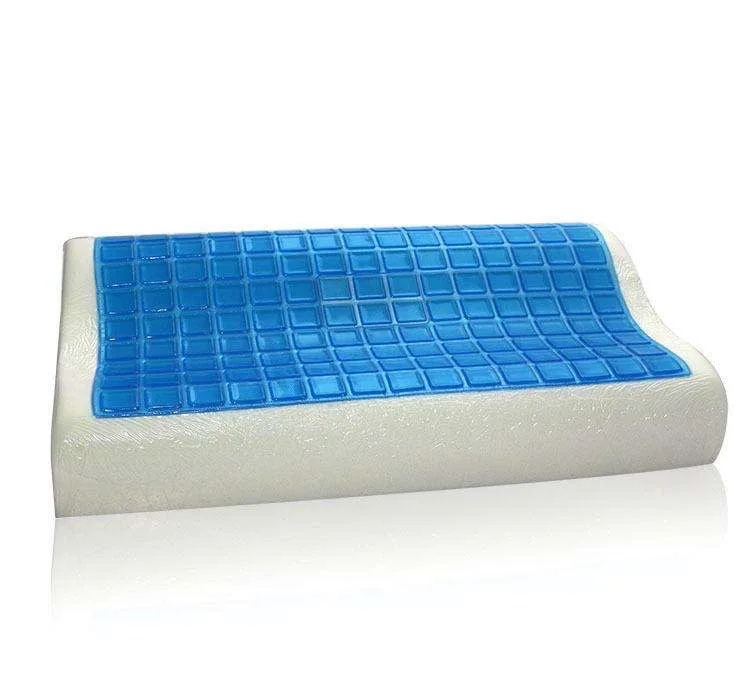

PU Silicone Pillow Insole Low Pressure Foaming Machine Automatic Springbuck Molding Foaming Production Machinery

- Section : Machinery

- Category : Plastic & Rubber Processing Machinery

- SKU : 1601193604932-1729509290

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Jan, 2025, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

Related Products

Recently Viewed Products

Customer Support

▲