B21, China Town Mall, Midrand

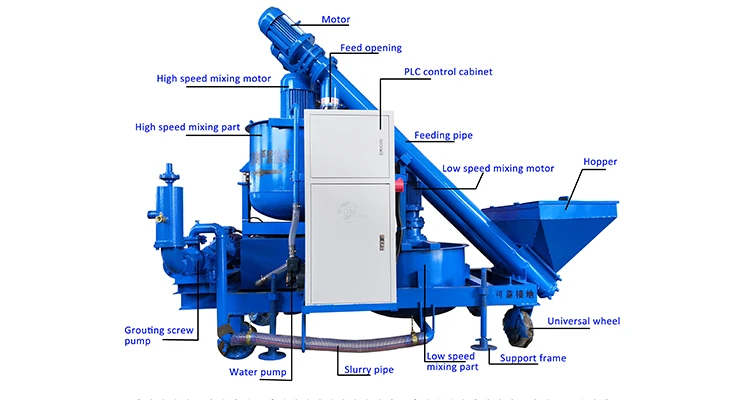

PLC Grouting System Post Tension Injection Cement Machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600441215433

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the PLC Grouting System Post Tension Injection Cement Machine (ZNYJ-Ⅱ-700) used for?

The ZNYJ-Ⅱ-700 is an intelligent, PLC-controlled grouting unit designed for post-tension (pre-stressed) tendon injection and general cementitious grouting. It integrates automatic water filling, slurry distribution, high- and low-speed mixers, vacuum pump, screw squeeze pump and electric valves for automated grout production and injection.

2. What are the key technical specifications of the ZNYJ-Ⅱ-700?

High-speed mixer speed 1100 rpm, single mixing capacity up to 500 kg, mixing measurement accuracy better than 0.2% (rated amount), high-speed motor 5.5 kW. Low-speed storage mixer speed 70 rpm, storage capacity up to 800 kg, low-speed motor 1.5 kW. Two spiral conveyors (motors), each 3 kW. Maximum slurry pressure 1.2 MPa with pressure display accuracy better than 1%. Overall weight ~1.2 t and dimensions 2900 mm × 1500 mm × 2300 mm.

3. What types of grout or materials can this machine handle?

The unit is intended for cement-based grouts used in post-tension injection (cement, water and common admixtures). Use of specialized resins or non-cementitious materials should be confirmed with the manufacturer before use.

4. How automated is the system and what does PLC control manage?

The PLC control manages automatic water filling, programmed slurry dosing and distribution, mixer operation, screw feeding, vacuum pump control, electric valves and pressure monitoring—enabling automated batch mixing, storage and injection sequences to reduce manual intervention.

5. What are the maximum batch and storage capacities?

Maximum single mixing (high-speed) capacity is 500 kg. The low-speed storage tank can hold up to 800 kg.

6. What is the maximum slurry pressure and pressure measurement accuracy?

Maximum slurry pressure is 1.2 MPa. The slurry pressure display has an accuracy better than 1%.

7. What level of measurement accuracy does the system provide for dosing?

The system provides measurement accuracy better than 0.2% for the rated mixing amount, ensuring consistent batch proportions.

8. What are the basic operating steps to produce and inject grout?

Typical workflow: verify power and leveled placement, program the PLC batch parameters, load cement and admixtures (automatic feeding handles bulk material), start the high-speed mixer for the measured batch, transfer mixed slurry to the storage mixer, use the screw squeeze pump and vacuum system for line priming and injection, and monitor pressure and PLC status during injection. Always follow the supplied operation manual and site procedures.

9. What electrical and site requirements are needed to install and run the machine?

The datasheet lists motor powers for components, but specific power supply voltage/current and connector details are not included here. A stable industrial power supply (typically three-phase) and proper grounding are required. For exact electrical specifications, circuit protection and site hookup instructions, consult the manufacturer's electrical documentation or contact the supplier.

10. How is the machine cleaned and what maintenance is required?

Clean mixers, discharge lines and pumps immediately after use by flushing with water to prevent grout setting. Regularly inspect and service seals, liners, pump components and valves. Maintain the vacuum pump per manufacturer recommendations, lubricate bearings and screw conveyors, and periodically calibrate sensors and weighing/dosing systems. Keep a maintenance log and use genuine spare parts.

11. What are common troubleshooting tips for performance issues?

For inconsistent mixes: verify water/cement ratios and check feeder calibration. For low discharge pressure: inspect pump, suction lines, valves and vacuum system for leaks or blockages. For clogs: stop, depressurize and clean lines; check particle size or mix fluidity. If PLC alarms occur, consult the error code log and operator manual; contact service if unresolved.

12. Is the equipment mobile and how is it transported on site?

The ZNYJ-Ⅱ-700 is described as easy to move; its weight is approximately 1.2 t and dimensions are 2900 × 1500 × 2300 mm. It can be relocated on site using suitable lifting equipment or a trailer/forklift per the manufacturer’s transport instructions and lifting points.

13. Are spare parts, commissioning and operator training available?

Spare parts, commissioning services and operator training are typically provided by the manufacturer or authorized dealers. Contact your supplier to arrange spare parts, recommended spares list, on-site commissioning and formal training packages.

14. What safety precautions should operators follow when using this grouting system?

Follow standard site PPE requirements (eye/hand protection, respiratory protection when handling dry cement), ensure pressure lines are secured and pressure relief/isolation procedures are known, lock out/tag out electrical sources before maintenance, never open pressurized lines, and adhere to the machine’s safety sections in the operator manual. Ensure only trained personnel operate the PLC and pumping systems.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading