B21, China Town Mall, Midrand

Plastic injection Molding Machine Pet Chair Making Container Pet Preform Pallet blow injection Molding Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600430769920

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 13 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main application of the Plastic Injection Molding Machine?

The Plastic Injection Molding Machine is primarily used for manufacturing plastic products, including pet chairs, containers, and preforms through injection molding and blow molding processes.

2. What technology does the machine adopt?

The machine adopts advanced European technology, featuring a hydraulic unit with proportional pressure and flow control for precise adjustments in pressure and speed.

3. How does the temperature control work in this machine?

The machine uses a closed-loop PID temperature control system, which ensures high precision in maintaining the desired temperature during the injection molding process.

4. What safety features are included in the machine?

The machine is equipped with two safety systems: one for machine safety and the other for electrical safety, ensuring the operators' safety during operation.

5. What materials are used for the molds?

The molds are produced using high-grade materials and incorporate hot runner technology, with imported steel for durability and a high-quality surface finish.

6. Can the machine's dimensions and specifications be customized?

Yes, the machine type and specifications can be customized based on customer inquiries to meet specific production needs.

7. What is the automatic level of operation?

The machine features a high level of automation, which minimizes manual labor requirements and enhances operational efficiency.

8. What is the clamping system of the machine?

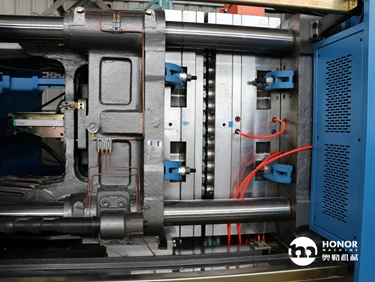

The machine uses a 5-point twin toggle clamping system designed through modular optimization for strong and stable clamping, meeting strict clamping conditions.

9. What type of hydraulic components does the machine use?

The machine utilizes famous imported hydraulic components to ensure low maintenance trouble and high operational reliability.

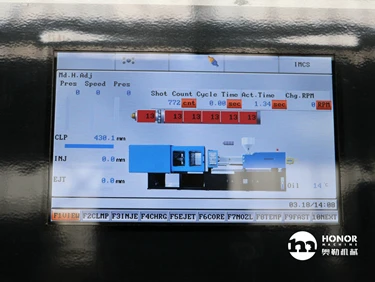

10. What kind of control unit does this machine have?

The control unit is an imported computer specifically designed for injection molding machines, featuring multiple functions and precise control processing.

11. How does the injection unit contribute to the molding quality?

The injection unit incorporates balanced double injection cylinder technology, ensuring evenly distributed force during fast injection, which significantly improves the injection quality.

12. What is the weight capacity of the machine models?

The weight capacity varies by model, ranging from 3.0 tons to 13.8 tons, depending on the specific clamping tonnage and specifications.

13. Is the machine suitable for mass production?

Yes, the machine is designed for high efficiency and can achieve a good product rate of over 99%, making it suitable for mass production of plastic items.

14. What languages are available on the display screen?

The LCD display screen has high clarity and supports both Chinese and English languages for user convenience.

15. Can the machine be used for different types of plastics?

Yes, the machine is designed to accommodate various types of plastics, and different screws can be developed to suit different injection conditions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading