B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Pizza Cone Machine and who is it for?

The Pizza Cone Machine is a commercial appliance that forms and bakes cone-shaped pizzas quickly and consistently. It's designed for pizzerias, food trucks, fast-casual restaurants and caterers who want a novel, portable pizza format.

2. What models and capacities are available?

There are multiple models that hold 2, 3 or 4 molds per cycle. Machine weight and footprint vary by model (examples: ~35–60 kg; sizes from ~380×350×980 mm up to 640×430×1120 mm). Molds can be customized to suit your product.

3. What are the electrical requirements and power consumption?

Models are available in common commercial configurations (110V/2600W and 220V/2600W options). Rated current is approximately 12A. Confirm the exact spec for the model you order.

4. What temperature range does the machine support?

Adjustable temperature control from 0°C up to 330°C, allowing you to fine-tune bake time and crust crispiness for different recipes.

5. How long does it take to make a pizza cone and what is the throughput?

Bake time depends on dough, filling and temperature but typically takes only a few minutes per cone. As a guideline, expect roughly 12–20 cones per hour per mold (so a 4‑mold machine could produce approximately 48–80 cones per hour) depending on settings and prep speed.

6. What types of dough and fillings can I use?

Use standard pizza doughs (thin or slightly thicker) and a wide variety of fillings—savory pizzas, vegetarian combos, and even sweet dessert cones. Avoid overly wet fillings that may make the dough soggy; pre-cook very wet ingredients or reduce moisture before filling.

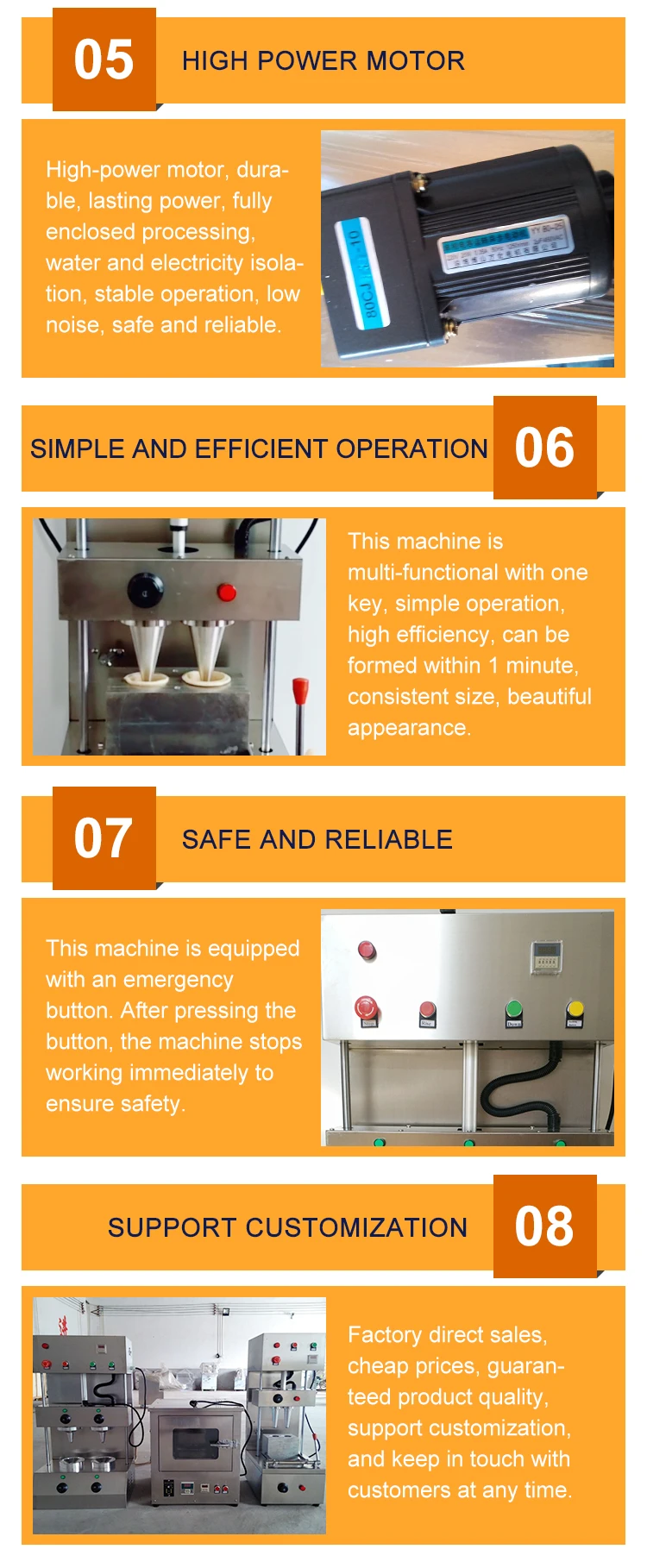

7. Is the machine easy to operate and how much training is required?

Yes. The machine is designed for simple operation: shape or place dough with fillings into the mold, set temperature and time, and start. Most staff learn operation in a short training session (minutes to an hour depending on menu complexity).

8. How do I clean and maintain the machine?

Turn off and unplug the unit and allow it to cool. Remove molds and any detachable parts, then clean with warm soapy water or food-safe cleaner. Wipe housing with a damp cloth. Non-stick surfaces reduce sticking—do not use abrasive tools on non-stick coatings. Regularly inspect seals, hinges and heating elements and schedule preventive maintenance as needed.

9. What materials is the machine made from?

The machine is built for commercial use with high-quality materials—typically a stainless-steel housing and non-stick molds—providing durability and easy cleaning. Confirm materials with your supplier for specific models.

10. Are replacement molds and spare parts available?

Yes. Replacement molds and common spare parts are available—check with the vendor or manufacturer for lead times and part numbers. Custom mold sizes can also be ordered in many cases.

11. Can the machine be used for catering or outdoor/food truck service?

Yes. The compact countertop design makes it suitable for food trucks, pop-ups and catering. Ensure your vehicle or venue has the correct power supply and ventilation for safe operation.

12. What safety features should I be aware of?

Standard safety practices include keeping hands and loose clothing away from hot surfaces, using heat-resistant gloves when handling molds, ensuring proper grounding and ventilation, and turning off/unplugging before cleaning. Follow all local electrical and food-safety regulations.

13. Can the machine produce dessert or non-pizza cone items?

Yes. The machine is versatile—use it for dessert cones (sweet dough, fruits, chocolate), stuffed bread cones or other creative fillings. Adjust temperature and time for different products.

14. Does the product come with certifications and warranty?

Certification (CE, UL, etc.) and warranty coverage can vary by region and model. Ask your supplier for certification documents and the warranty terms specific to the unit you plan to purchase.

15. How do I order, and what are typical lead times and installation requirements?

Order through the manufacturer or authorized dealer. Lead time depends on stock and customization (molds, voltage options)—ask the seller for current delivery estimates. Installation is typically plug-and-play for standard power models, though commercial setups may require professional electrical hookup and adequate ventilation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading