B21, China Town Mall, Midrand

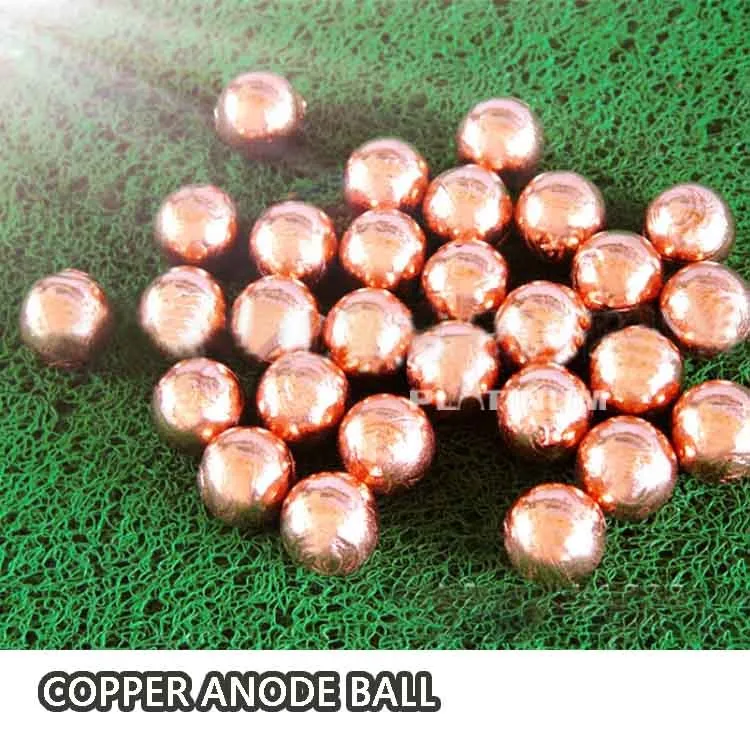

phosphor anode copper ball skew rolling cold rolling machine

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 60804645387

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the phosphor anode copper ball cold rolling machine?

The primary function of the phosphor anode copper ball cold rolling machine is to produce phosphorous copper balls, specifically for use in the copper industry, including applications in Printed Circuit Boards Electroplating and Industrial and Plastic Electroplating.

2. What are the key features of this machine?

Key features include the new technology of skew rolling for anode phosphorous copper balls, a durable whole material movable knife plate, increased roll life, convenient disassembly and maintenance with a split body design, and excellent shock resistance.

3. How does this machine improve production efficiency?

This machine improves production efficiency by saving manpower and providing stable performance, allowing for higher production rates of copper balls compared to traditional methods.

4. What is the production capacity of the machine?

The machine is designed for the production of Φ25 copper balls, which is a common size used in various electroplating processes.

5. Is there a need for a foundation to install the machine?

No, the one-piece high-strength base allows the machine to be used on the ground without requiring an installation foundation, making it more convenient to set up.

6. What safety features does the machine have?

The machine includes multiple protection links that enhance safety during operation, ensuring a secure working environment.

7. How long is the roll life compared to similar machines?

The roll life of this machine is increased to double that of similar machines, resulting in reduced maintenance and replacement costs.

8. Can the machine be easily maintained?

Yes, the split body design of the machine allows for easy disassembly and maintenance, making it user-friendly and efficient to service.

9. What materials can be processed with this machine?

The machine is specifically designed for processing phosphorous copper to produce copper balls, primarily used in electroplating applications.

10. What is the weight of the machine?

The machine has a weight of 4 tons, which contributes to its stability and shock resistance during operation.

11. Is training provided for operating the machine?

Yes, typically training is provided to ensure that operators are familiar with the machine's functionalities and safety protocols.

12. What industries benefit from using this machine?

Industries that benefit from this machine include electronics manufacturing, particularly those involved in PCB production, as well as various sectors engaged in electroplating.

13. What is the durability of the movable knife plate?

The movable knife plate is made of whole material, providing excellent strength and durability to withstand the rigors of continuous operation.

14. How is the performance of this machine compared to traditional rolling methods?

This machine offers superior performance through its advanced skew rolling technology, resulting in better quality and consistency of the copper balls compared to traditional rolling methods.

15. Is the machine suitable for large-scale production?

Yes, the machine is designed to meet the needs of large-scale production in the copper industry, providing efficiency and stability in operations.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading