B21, China Town Mall, Midrand

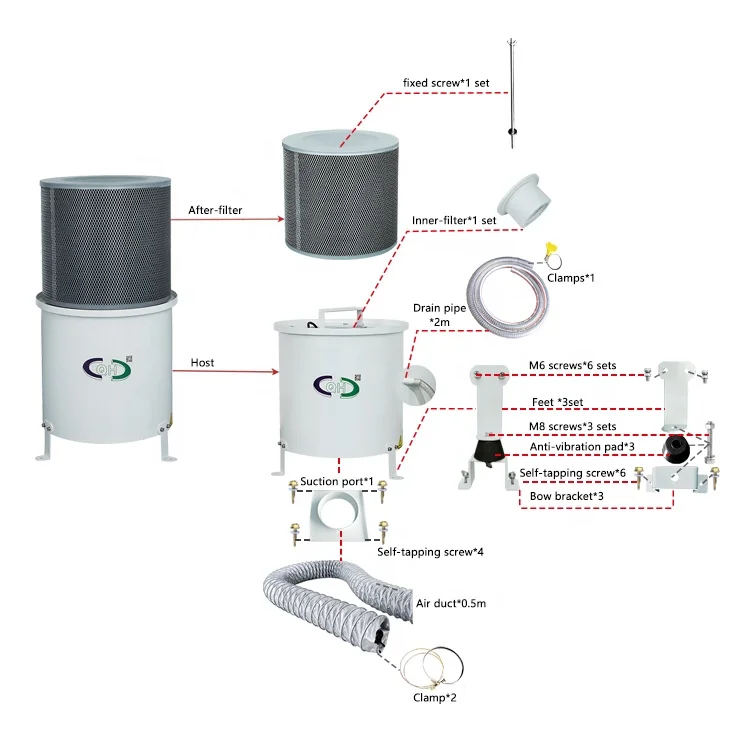

Oil Mist With Small Size And Light Weight And Large Air Volume And Low Energy Consumption

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601051142962

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 24 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Compact Oil Mist Collector used for?

The unit collects and purifies oil mist and aerosol generated by machining centers, CNC lathes, cleaning equipment, cold forging machines, grinders, corers and similar manufacturing processes to improve workplace air quality and protect equipment.

2. What are the airflow and power specifications?

Air volume ranges from 300 to 2000 m³/h (models available across this range). Rated power is 0.12–0.75 kW depending on the model.

3. What are the voltage and frequency options?

Standard configuration is 3-phase 380V, 50Hz. Customized voltage/frequency options are available on request to suit local power supplies.

4. How energy efficient is this collector?

The collector is designed for high air volume with low energy consumption; typical power draw across models is between 0.12 and 0.75 kW, providing efficient cleaning while minimizing electricity cost.

5. Does the product require consumable filters?

No consumable filters are required according to the product description, which reduces ongoing operating costs. Contact the supplier for details about any occasional replaceable wear parts.

6. What maintenance is required and how often?

Routine maintenance generally includes emptying/removing collected oil, visually inspecting and cleaning collection components, and checking fan and electrical connections. Frequency depends on usage intensity — inspect weekly to monthly and follow the supplier's maintenance guidance.

7. What warranty and after-sales support are provided?

The product comes with a 1-year warranty for the full machine and core components. The supplier also provides a machinery test report, outgoing inspection video, and online support after the warranty period.

8. What are the noise levels during operation?

Noise levels vary by model and operating point, typically in the range of 59–70 dB.

9. What suction inlet sizes are available?

Suction diameters are available in the range of 100–250 mm to fit common ducting and hoods.

10. What is the maximum static pressure the unit can handle?

The collector can handle static pressures in the range of approximately 100–800 Pa, depending on model and configuration.

11. Is the unit easy to install and move?

Yes — the compact, lightweight design makes installation and relocation straightforward. Specific mounting or mobility accessories (casters, brackets, duct kits) may be available from the supplier.

12. Can one unit cover multiple workstations or capture points?

Coverage depends on required capture efficiency, ducting layout and distance. In many cases a single appropriately sized unit can serve a small cell or machine group; for larger areas or multiple distant points, multiple units or a ducted system are recommended. Contact the supplier with your floor plan and capture requirements for sizing guidance.

13. Are safety or compliance certificates available?

The supplier provides a machinery test report and inspection video. For specific certifications (CE, UL, local approvals), ask the supplier at time of purchase — many certification options can be provided or arranged per customer requirements.

14. How do I choose the correct model for my application?

Select a model based on required capture airflow (m³/h), suction inlet size, static pressure losses from ducting/hoods, and noise or size constraints. Provide details about the machine type, number of machines, distance to the collector, and typical oil mist generation when contacting sales for a recommended model and quotation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading