B21, China Town Mall, Midrand

ODETOOLS VHB-200 3 in 1 Multifunctional Cutting, Bending, and Punching Machine

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600507271340

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

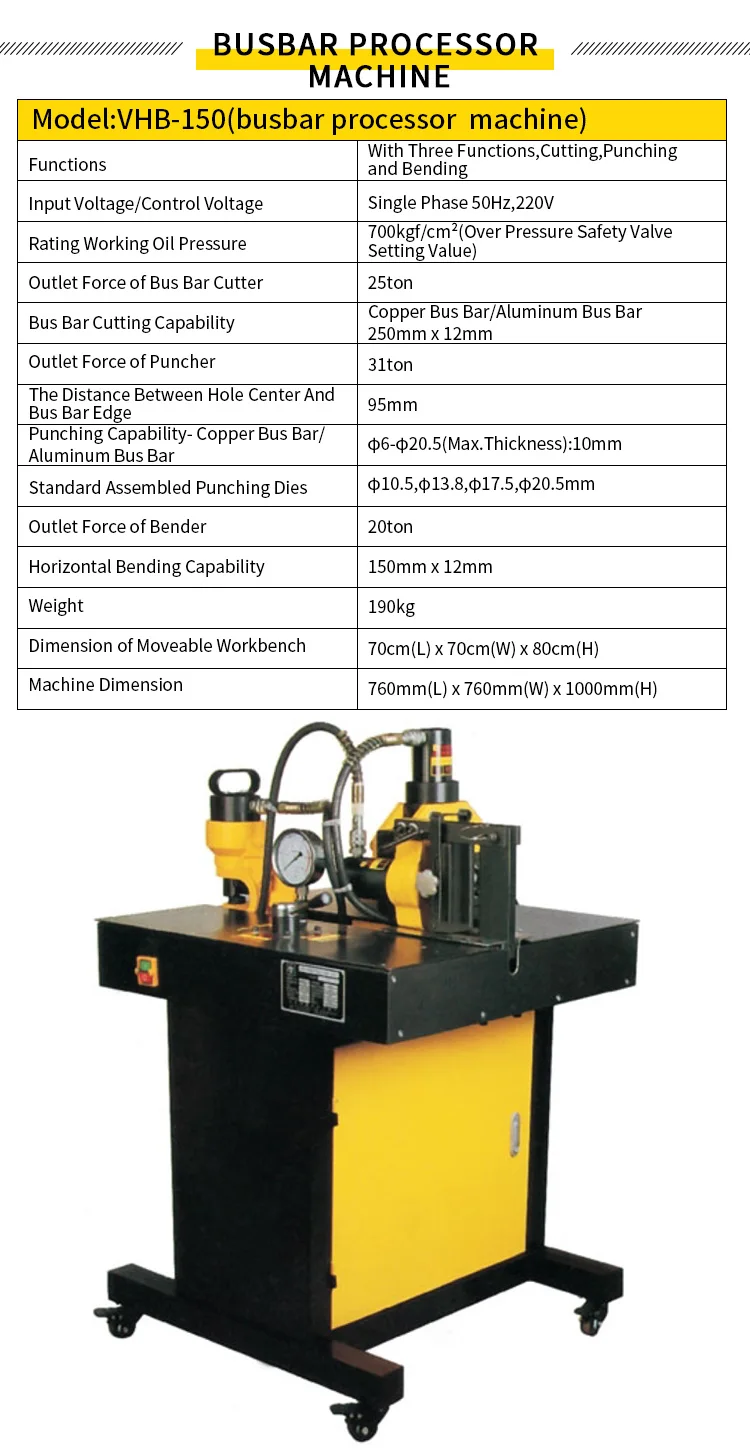

1. What is the ODETOOLS VHB-200 3 in 1 machine designed to do?

The VHB-200 is a multifunctional metalworking machine that performs cutting, bending, and punching operations. It is intended for professional use in manufacturing and construction, especially for processing busbars and similar metal components.

2. What are the key specifications of the VHB-200?

Key specs include a machine weight of 230 kg, overall dimensions 105 cm x 75 cm x 130 cm, cutting force 20 tons, punching force 35 tons, bending force 20 tons, and rated oil pressure of 700 kg/cm². It also includes machinery test report and outgoing inspection video.

3. What materials and sizes can the machine handle?

The machine is designed to cut and bend copper and aluminum busbars up to 250 mm x 12 mm (cutting) and perform horizontal bending up to 200 mm x 12 mm. It can also work with other soft metals — consult the supplier for steel or harder materials.

4. What are the cutting, punching, and bending capacities?

Cutting force: 20 tons (suitable for busbars up to 250 x 12 mm). Punching force: 35 tons (supports various mold sizes). Bending force: 20 tons (horizontal bending up to 200 x 12 mm).

5. Which punching mold sizes are compatible with the VHB-200?

The machine accommodates punching molds with nominal sizes of 10.5 mm, 13.8 mm, 17.5 mm, and 20.5 mm. Custom molds may also be used or ordered from the manufacturer.

6. What are the machine's physical dimensions and weight?

Overall dimensions are 105 cm (length) x 75 cm (width) x 130 cm (height), and the machine weighs approximately 230 kg.

7. What hydraulic/oil pressure does the VHB-200 operate at?

The machine is rated to operate at an oil pressure of 700 kg/cm².

8. What power supply or motor requirements does the machine need?

Electrical and motor specifications are not provided in the product description. Please contact ODETOOLS or your supplier for motor power, voltage, and wiring requirements specific to your region.

9. Is installation and commissioning included, and what is required for setup?

Installation and commissioning policies vary by seller. The machine requires a stable, level floor and adequate workspace for operation. Professional installation and hydraulic/oil fill and bleed are recommended — confirm with your supplier whether on-site setup is included or offered as an add-on.

10. What safety features and precautions should I follow when using the VHB-200?

Follow standard machine safety: use guards and barriers, wear PPE (safety glasses, gloves, hearing protection as appropriate), ensure emergency stop is functional, lock out/tag out during maintenance, and train operators on safe operating procedures. Verify all safety devices before use.

11. What routine maintenance does the machine require?

Regular maintenance should include checking and topping up hydraulic oil, inspecting hoses and fittings for leaks, changing hydraulic filters per schedule, lubricating moving parts, checking fasteners, and periodic inspection of tooling and molds. Follow the manufacturer's maintenance manual for intervals and procedures.

12. Are spare parts, replacement molds, and tooling available?

Spare parts and molds are typically available from the manufacturer or authorized dealers. Contact ODETOOLS or your supplier to order replacement punches, dies, seals, or custom tooling compatible with the VHB-200.

13. What quality assurance is provided with the machine?

The product is supplied with a machinery test report and an outgoing inspection video, which document functional testing and quality checks prior to shipment.

14. What warranty and after-sales support are offered?

Warranty coverage and after-sales support vary by seller and region. The product description indicates quality inspections are provided, but you should confirm warranty length, service terms, and availability of technical support with the seller before purchase.

15. What is the typical cycle time or production speed for cutting, bending, and punching?

Cycle time depends on material, tooling, and operator. Simple cutting or punching operations can often be completed in seconds, but exact throughput should be confirmed with ODETOOLS or tested on sample parts to determine production rates for your specific application.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading