B21, China Town Mall, Midrand

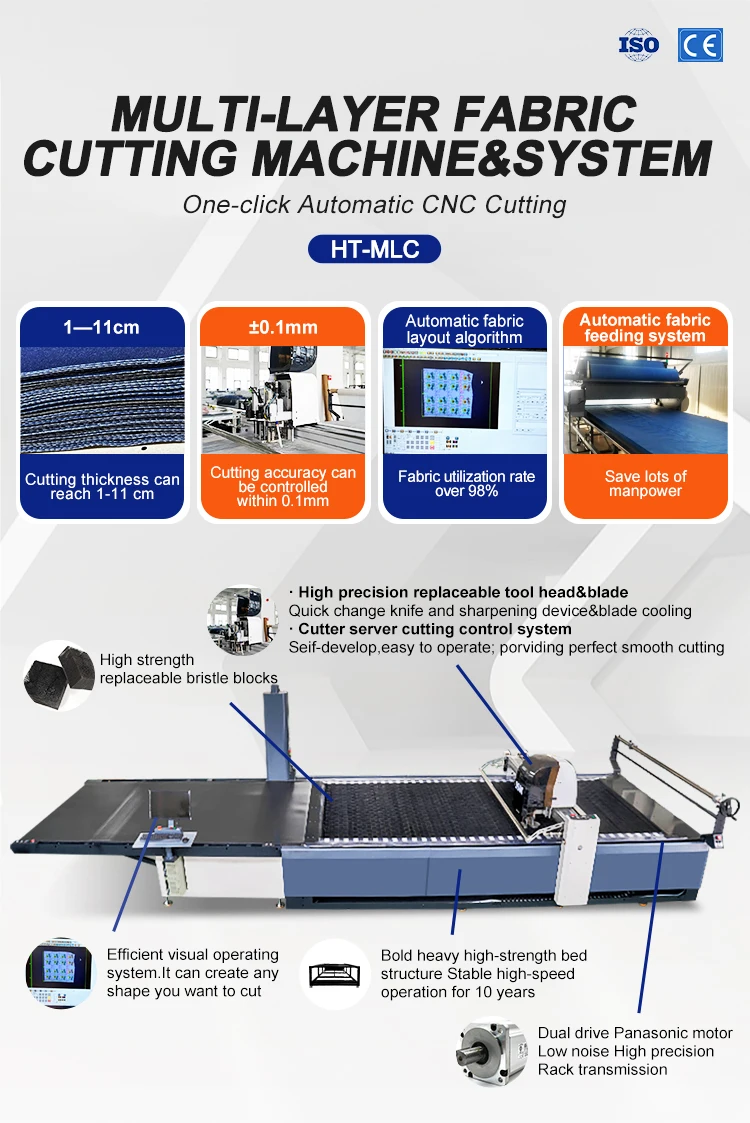

Multi High Layer Ply Fabric Pants Cotton Cutting CNC Bullmer Machine Cut Jeans Suits Cloth Fabric Cutting Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601048566357

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 01 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of fabrics can the Multi High Layer Ply Fabric Pants Cutting Machine cut?

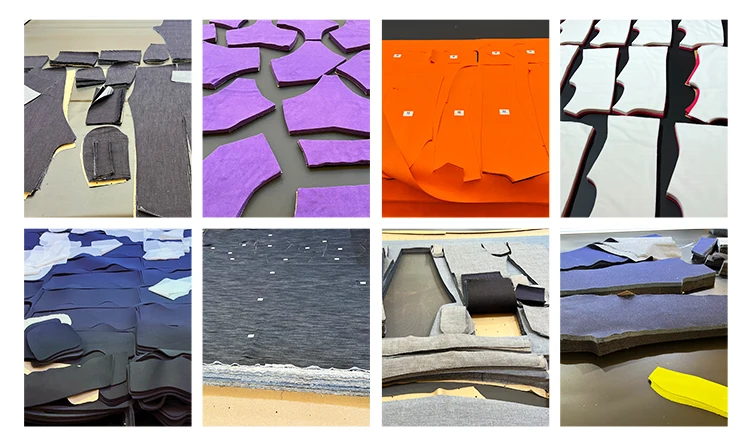

The machine can cut a variety of materials including fabric, textiles, lace, leather, denim, foam, PVC, cardboard, and more.

2. What is the maximum cutting thickness of the machine?

The machine can cut materials with a thickness ranging from 0.1mm to 110mm.

3. What is the production capacity of the cutting machine?

The machine can produce up to 650 pairs of pants per hour, 500 pieces of clothing per hour, and 6000 pieces of medical gowns per hour.

4. What is the maximum cutting speed of the machine?

The maximum cutting speed is 70m/min.

5. Is the cutting length limited?

No, there is no limitation on the cutting length due to the automatic fabric feeding system.

6. What power supply does the machine require?

The machine requires a power supply of 220V/380V, 50/60Hz.

7. How does the machine ensure cutting accuracy?

The machine offers a cutting precision of ±0.1mm and utilizes high-speed cameras for precise positioning.

8. Can the machine be customized to specific sizes?

Yes, the machine model is customizable and can accommodate different cutting ranges.

9. What safety features does the machine have?

The machine is equipped with an inductive safety protection device to ensure safe operation.

10. How does the automatic feeding system work?

The automatic feeding system utilizes a crawler conveyor for seamless material receiving and feeding.

11. What are the main components of the cutting machine?

The main components include an automatic multi-layer cutting bed, an automatic cloth spreading machine, and an air flotation table.

12. Does the machine come with a warranty?

Yes, the machine comes with a three-year warranty and offers 24/7 customer service.

13. What is the role of the intelligent graphic layout software?

The intelligent graphic layout software allows for efficient design and fabric layout, maximizing material utilization rates over 98%.

14. What types of accessories are included with the machine?

Accessories include a motor, guide rail, switch, knife drive, and conveyor belt among others.

15. Is the blade of the machine easy to maintain?

Yes, the blades are replaceable and easy to load and unload, and the machine is equipped with an automatic spin double-sided sharpening device.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading