B21, China Town Mall, Midrand

MC1500 Mobile Concrete Batching Plant – Flexible, Efficient, and Powerful Concrete Mixing

- Section : Machinery

- Category : Concrete Mixers

- SKU : 60822828211

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the MC1500 Mobile Concrete Batching Plant and what are its main uses?

The MC1500 is a mobile concrete batching plant designed for high-output on-site concrete production. It suits medium to large construction projects — roads, bridges, infrastructure, and ready-mix operations — especially where mobility and quick setup are required.

2. What production capacity does the MC1500 deliver?

The MC1500 produces approximately 20–25 m³ of concrete per hour with a 750 L discharge capacity per batch, providing a steady supply for medium to large projects.

3. What are the key technical specifications (size, weight, power)?

Work size: 6581 x 2530 x 2937 mm; weight: 8.8 t; mixing power: 30 kW; discharge capacity: 750 L; capacity: 20–25 m³/h. For full electrical specifications and local power requirements, consult the supplier.

4. Is the MC1500 easy to transport and set up on site?

Yes. The plant is mobile and compact for fast transport and quick setup. It requires no permanent foundation, making it easy to move between sites and start production quickly.

5. Can the discharge height be customized?

Yes. The MC1500 offers a customizable discharge height up to 3.8 m to accommodate different truck heights and site requirements.

6. What type of mixer does the MC1500 use and how reliable is it?

The MC1500 uses a planetary concrete mixer (brand: SDDOM), which provides powerful, consistent mixing performance suitable for large batch production and long service life when maintained properly.

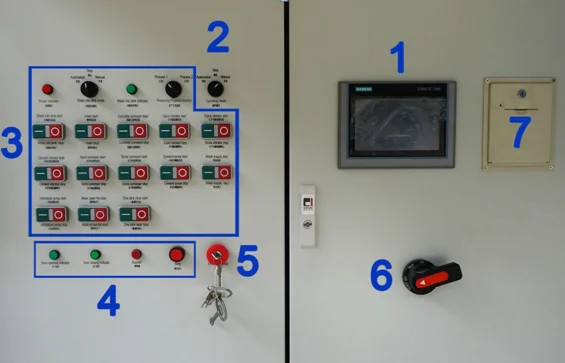

7. What control system does the plant use?

It uses a Siemens PLC with a touch control interface. Features include automatic/manual selection, mixing time/volume/formula settings, indicator/alarm lights, emergency stop, and an onboard printer.

8. What core components are included and are they durable?

Core components include engine, bearings, pressure vessel, gears, and pump. These high-quality parts are selected for durability and long-term reliable operation.

9. Does the MC1500 meet international standards and how is quality verified before delivery?

The plant is designed according to Europe CE standards. Each unit undergoes video outgoing inspection and a machinery test report is provided to verify operational readiness prior to shipment.

10. What warranty and after-sales support come with the MC1500?

A 12-month warranty is provided. The plant is shipped with inspection reports and the manufacturer/supplier provides support for delivery, commissioning, and after-sales service — contact your supplier for specific service terms.

11. What packaging and shipping arrangements are available?

Standard packing is used for safe transport. Units ship from Qingdao Port for international delivery. Shipping details and FOB/EXW terms should be confirmed with the supplier.

12. Are there optional parts or accessories available?

Optional accessories include a screw conveyor. Additional accessories or customizations (e.g., different discharge heights, auxiliary conveyors) can be discussed with the supplier.

13. What safety features are built into the MC1500?

Safety features include emergency stop, indicator and alarm lights, and PLC-controlled interlocks. Standard safe operating procedures should be followed on site.

14. How many operators are required and is training provided?

The MC1500 can typically be operated by one trained operator with support personnel for loading and logistics. Supplier-provided training during commissioning is recommended and often available.

15. What routine maintenance is recommended to ensure long service life?

Perform daily visual inspections and cleaning, check and maintain lubrication points, monitor wear parts (mixer blades, bearings, seals), and follow the manufacturer's maintenance schedule. Keep a stock of critical spare parts and consult the manual or supplier for detailed maintenance intervals.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading