B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

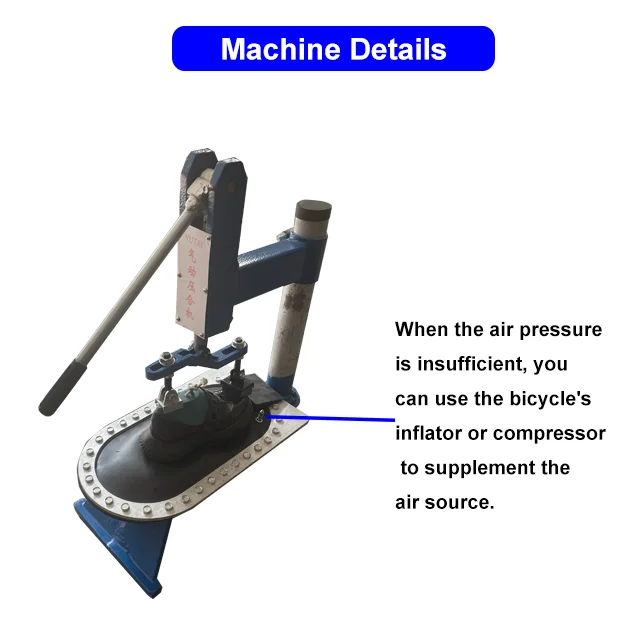

1. What are the physical dimensions of the Manual Sole Pressing Machine?

The mechanical size is 700 × 270 × 680 mm. The machine ships in a packed size of 770 × 340 × 750 mm.

2. How much does the machine weigh?

The mechanical (net) weight is 31.5 kg. The total packed weight is 39 kg.

3. Is electrical power required to operate this machine?

No. This is a manual sole pressing machine and is operated by hand, so no electrical connection is required.

4. What types of soles and materials can this machine press?

It is designed for common shoe sole materials such as rubber, PU, EVA and leather. For specialized materials or adhesives, test on sample parts or consult the manufacturer.

5. What is the maximum sole size or thickness the machine can accommodate?

The supplied specifications do not list a specific maximum sole size or thickness. The machine is intended for standard shoe sole applications—contact the supplier with sample dimensions for confirmation if you work with oversized or unusually thick soles.

6. How do I install and set up the Manual Sole Pressing Machine?

Unpack the machine from its packing (770 × 340 × 750 mm), place it on a stable, level workbench, secure any fasteners if included, and perform a functional check following the user manual. No electrical hookup is required. If a manual is not provided, ask the supplier for setup instructions.

7. What routine maintenance is required?

Regularly clean the pressing surfaces, remove adhesive residue, lubricate moving joints per the manufacturer’s instructions, and inspect bolts and fasteners for tightness. Replace worn pads or parts as needed to maintain consistent pressure and alignment.

8. Are replacement parts or service available?

Replacement parts and service availability depend on the supplier. Contact the manufacturer or vendor to order spare parts (pads, springs, fasteners) and to inquire about repair or maintenance services.

9. What safety precautions should I follow when using the machine?

Keep fingers and hands clear of the pressing area during operation, wear appropriate PPE (gloves and eye protection), ensure the machine is on a sturdy surface to prevent tipping, and follow any safety guidance in the product manual.

10. How is the machine packaged for shipping?

The machine is packed to the dimensions 770 × 340 × 750 mm and the packed weight is 39 kg. Packaging typically includes protective materials to prevent damage during transport.

11. Can the machine be customized (size, press plates, fixtures)?

Customization options vary by manufacturer. Many suppliers can provide custom press plates, fixtures, or minor dimensional changes—contact the vendor with your requirements to discuss feasibility, pricing, and lead time.

12. What is the expected lead time for delivery?

Lead time depends on the supplier’s stock and your location. Ask the vendor or their sales representative for current lead times and shipping options.

13. Does the machine come with a warranty?

Warranty terms vary by supplier. Check product listing or contact the manufacturer for details on warranty duration, coverage, and claiming procedures.

14. What should I do if the press is not providing enough pressure or is misaligned?

Inspect for loose fasteners, worn or contaminated pressing surfaces, or bent components. Clean and lubricate moving parts, tighten hardware, and replace worn pads. If problems persist, consult the supplier or a qualified technician for repair.

15. Is there a recommended operating environment for the machine?

Use the machine in a dry, well-ventilated workspace on a stable, level surface. Avoid extreme temperatures and excessive humidity to prevent corrosion and adhesive curing issues.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals