B21, China Town Mall, Midrand

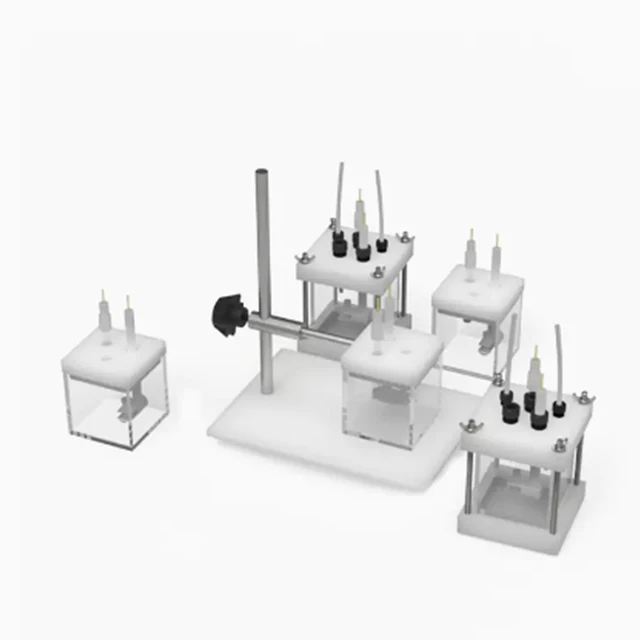

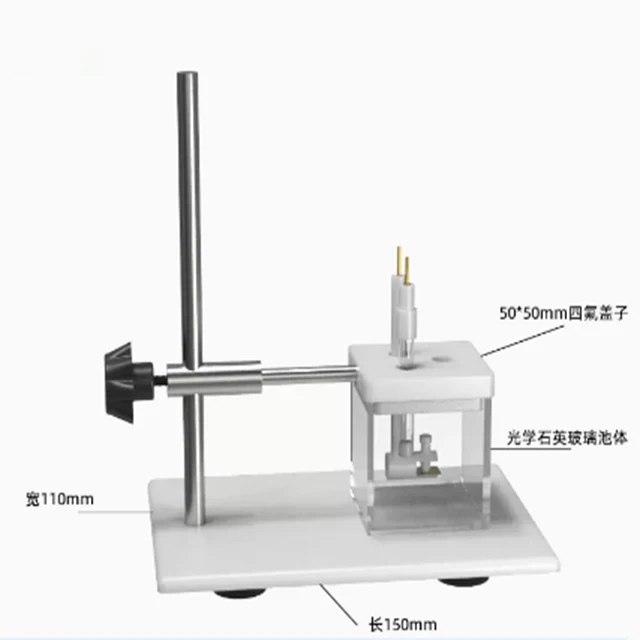

Laboratory Electrochemical Cell For Quartz Glass

- Section : Medical Supplies

- Category : Other Lab Supplies

- SKU : 1600990134757

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 19 Jan, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Laboratory Electrochemical Cell for Quartz Glass used for?

It is a compact electrolytic cell designed for precision electrochemical experiments (three-electrode measurements, electrolytic tests and related analyses) in laboratories and industrial research settings.

2. What materials is the cell made from?

The cell body and wetted parts are made of high-quality quartz glass and PTFE, providing chemical resistance and durability.

3. How many electrode ports does the cell have and what size are they?

The cell has three electrode holes, each 6 mm in diameter, suitable for standard working, reference and counter electrodes up to 6 mm.

4. What is the operating temperature range?

The cell is rated for use from ambient (normal) temperature up to 60°C. It is not intended for high-temperature applications above 60°C.

5. What are the external dimensions and how much sample does it hold?

External dimensions are 50 mm × 50 mm × 50 mm. Internal usable volume depends on wall thickness and internal geometry; contact the manufacturer for the exact internal volume.

6. How is the cell sealed to prevent leaks?

Sealing is accomplished using a threaded closure combined with a rubber O-ring, providing a secure, leak-resistant seal when properly assembled.

7. How should I assemble and tighten the threaded seal?

Align parts carefully, seat the rubber ring and hand-tighten the thread until snug. Avoid excessive torque to prevent stress on the quartz glass. If stronger sealing is required, follow manufacturer's torque guidance if provided.

8. Which chemicals are compatible with quartz and PTFE parts?

Quartz glass and PTFE are resistant to most acids, bases and organic solvents. However, quartz is attacked by hydrofluoric acid (HF) and certain fluoride-containing reagents — avoid HF and consult the manufacturer for compatibility with highly aggressive reagents.

9. How should the cell be cleaned?

Rinse with deionized water and mild laboratory detergents for routine cleaning. For organic residues, use suitable organic solvents (ethanol, acetone) that are compatible with PTFE. Avoid HF and abrasive cleaners. Do not autoclave unless the manufacturer explicitly states autoclave compatibility.

10. Is the cell suitable for sterilization by autoclaving or high heat?

No — the specified applicable temperature is up to 60°C, so autoclaving (typically 121°C) and other high-temperature sterilization methods are not recommended. Use chemical sterilants or UV methods compatible with quartz and PTFE if sterilization is required.

11. Can I use my standard potentiostat and electrode leads with this cell?

Yes — the cell is designed for standard three-electrode electrochemical setups. Ensure your electrodes fit the 6 mm ports and use appropriate leads or adapters to connect the electrodes to your potentiostat.

12. How do I check or replace the rubber sealing ring?

Inspect the rubber ring regularly for cracks, chemical attack or deformation. Replace it if damaged. Contact the manufacturer or supplier for compatible replacement O-rings sized for the cell’s thread.

13. What precautions should I take when handling and storing the cell?

Handle with care to avoid mechanical shock or dropping. Store dry, protected from impact and extreme temperatures. Keep rubber seals away from prolonged ozone or harsh sunlight that could degrade them.

14. Who should I contact for custom configurations, spare parts or technical specifications not listed?

Contact the product manufacturer or authorized distributor for detailed technical drawings, exact internal volume, spare O-rings, custom electrode port modifications or any other specific requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals