B21, China Town Mall, Midrand

Laboratorial Foam Concrete Machiner

- Section : Machinery

- Category : Other Construction Machinery

- SKU : 1600874900687

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 22 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary use of the Laboratorial Foam Concrete Machine?

The Laboratorial Foam Concrete Machine is designed for producing foam concrete in laboratory settings, making it ideal for research and testing purposes.

2. What are the key features of the Laboratorial Foam Concrete Machine?

Key features include high operating efficiency, compact weight (24 kg), durable core components, versatile application for foam concrete, ISO certification, user-friendly design, and pH balance of 7.5 in a 20% solution.

3. What is the weight of the Laboratorial Foam Concrete Machine?

The machine weighs 24 kg, making it easy to transport and fit into various laboratory spaces.

4. Is the Laboratorial Foam Concrete Machine user-friendly?

Yes, the machine features a straightforward design and operation, making it suitable for technicians and researchers alike.

5. What is the minimum order quantity for this machine?

The minimum order quantity for the Laboratorial Foam Concrete Machine is just 1 unit.

6. Are samples available for testing before purchasing the machine?

Yes, samples are available for testing, allowing you to evaluate the machine's performance before making a commitment.

7. What are the dimensions of the Laboratorial Foam Concrete Machine?

The dimensions of the machine are 41 cm x 34 cm x 54 cm.

8. What kind of certification does the Laboratorial Foam Concrete Machine have?

The machine is ISO 9001:2015 certified, ensuring high-quality manufacturing processes.

9. What is the maximum foam output of the Laboratorial Foam Concrete Machine?

The maximum foam output is between 3 to 5 m³/h.

10. What is the motor voltage required for this machine?

The Laboratorial Foam Concrete Machine operates on a motor voltage of 220V.

11. How does the foam produced by this machine benefit foam concrete?

The foam produced is uniform, improving the strength and thermal insulation performance of foam concrete.

12. What is the maximum foaming volume the machine can achieve?

The maximum foaming volume is about 100L/min, depending on the foaming agent used.

13. What precautions should I take when using the foaming liquid suction pipe?

Be careful not to remove the filter from the foaming liquid suction pipe to prevent impurities from blocking the pump.

14. Can the Laboratorial Foam Concrete Machine be used for various foaming agents?

Yes, different foaming agents can be used, but they will have various dilution factors affecting foam density.

15. How do I make foam concrete using this machine?

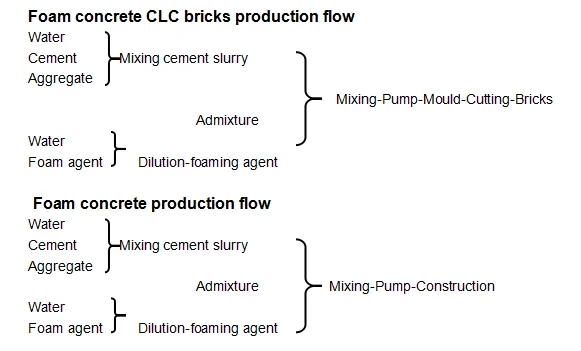

You can use a mixing bucket to make pulp, then foam the mixture on top of the slurry. After stirring, the slurry can be mixed with foam to create foam concrete, minimizing stirring time and using low speed.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading